Method for combined remediation of heavy metal contaminated soil through curing agent and microorganisms

A technology of combined restoration of contaminated soil, applied in the restoration of contaminated soil, etc., can solve the problems of easy death of microorganisms, achieve the effect of reducing the dissolution rate, reducing the concentration of leaching, and inhibiting cadmium pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

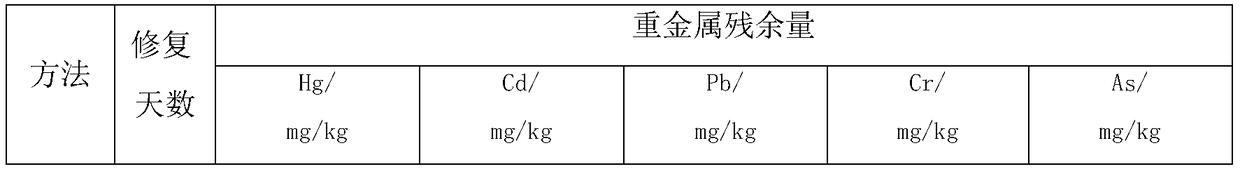

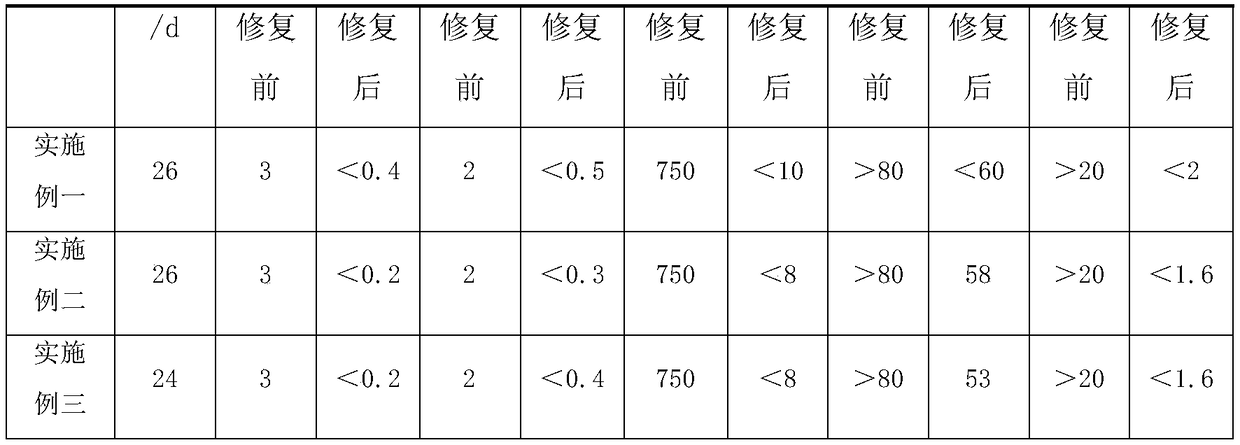

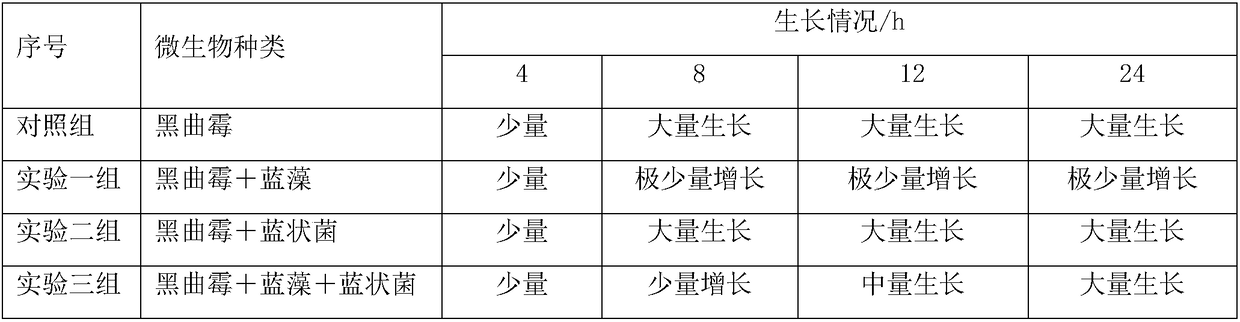

Examples

Embodiment 1

[0029] A kind of solidifying agent and the method for the joint restoration of heavy metal polluted soil of microorganism, comprise the following steps:

[0030] S1: Lay an anti-seepage membrane at a depth of 30cm in the heavy metal-contaminated soil, and break up the overturned soil agglomerates;

[0031] S2: uniformly mix the curing agent and the heavy metal-contaminated soil to obtain a mixed system, and the mass ratio of the curing agent to the heavy metal-contaminated soil is 1:100;

[0032] S3: Add water to the mixed system, so that the water content of the mixed system is 35%, and the standing time is 10 days;

[0033] S4: Dig a water diversion ditch around the heavy metal contaminated soil, and lay an anti-seepage film at the bottom of the water diversion ditch;

[0034] S5: washing the soil with water for 3 times;

[0035] S6: Spray the sterilizing solution on the soil to sterilize the soil. The spraying rate is 0.5 tons per mu per hour, stop for 1 hour after 3 hour...

Embodiment 2

[0041] S1: Lay an anti-seepage membrane at a depth of 50cm in the heavy metal-contaminated soil, and break up the overturned soil agglomerates;

[0042] S2: uniformly mix the curing agent and the heavy metal-contaminated soil to obtain a mixed system, and the mass ratio of the curing agent to the heavy metal-contaminated soil is 3:100;

[0043] S3: Add water to the mixed system, so that the mixed system and water content are 50%, and the standing time is 15 days;

[0044] S4: Dig a water diversion ditch around the heavy metal contaminated soil, and lay an anti-seepage film at the bottom of the water diversion ditch;

[0045] S5: washing the soil with water for 5 times;

[0046] S6: Spray the sterilizing solution to the soil to sterilize the soil, the spraying rate is 1 ton per mu per hour, stop for 2 hours after 4 hours of treatment, and then continue the treatment for 2 consecutive days, the sterilizing solution is copper sulfate aqueous solution , the concentration of the ...

Embodiment 3

[0051] S1: Lay an anti-seepage membrane at a depth of 40cm in the heavy metal-contaminated soil, and break up the overturned soil agglomerates;

[0052]S2: uniformly mix the curing agent and the heavy metal-contaminated soil to obtain a mixed system, and the mass ratio of the curing agent to the heavy metal-contaminated soil is 2:100;

[0053] S3: Add water to the mixed system, so that the water content of the mixed system is 45%, and the standing time is 13 days;

[0054] S4: Dig a water diversion ditch around the heavy metal contaminated soil, and lay an anti-seepage film at the bottom of the water diversion ditch;

[0055] S5: washing the soil with water for 4 times;

[0056] S6: Spray the sterilizing solution on the soil to sterilize the soil. The amount of spraying is 0.8 tons per mu per hour. After 3.5 hours of treatment, stop for 1.5 hours, and then continue the treatment for 1.5 days. The sterilizing solution is sulfuric acid Copper aqueous solution, the concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com