Catalyst for alkylation of toluene and methanol and preparation method thereof

A catalyst and alkylation technology, which is applied in the direction of carbon compound catalysts, physical/chemical process catalysts, catalysts, etc., can solve the problems of cumbersome catalyst preparation technology, improved catalytic activity of toluene and methanol alkylation, and achieve high selectivity, The effect of high conversion rate of toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of catalyst of the present invention comprises the steps:

[0021] (i) mixing the EU-1 molecular sieve with a binder to form a carrier, the EU-1 molecular sieve in the carrier is hydrogen type,

[0022] (ii) impregnating the carrier prepared in step (i) with a solution of a boron-containing compound and a magnesium-containing compound, drying and calcining the impregnated carrier.

[0023] The EU-1 molecular sieve preparation method described in the above (i) step comprises the steps:

[0024] (1) Mix silicon source, aluminum source, inorganic base, templating agent, surfactant and water to make reactants, so that the molar ratio of each material is:

[0025] 0.1~0.7R: 0.001~0.3M: 0.02~0.1Na 2 O: 0.003~0.05Al 2 o 3 : SiO 2 : 10~100H 2 o

[0026] Wherein, R is the template agent for preparing EU-molecular sieves, M is a surfactant, and the amount of the silicon source is represented by SiO 2 In terms of, the amount of aluminum source is Al ...

example 1

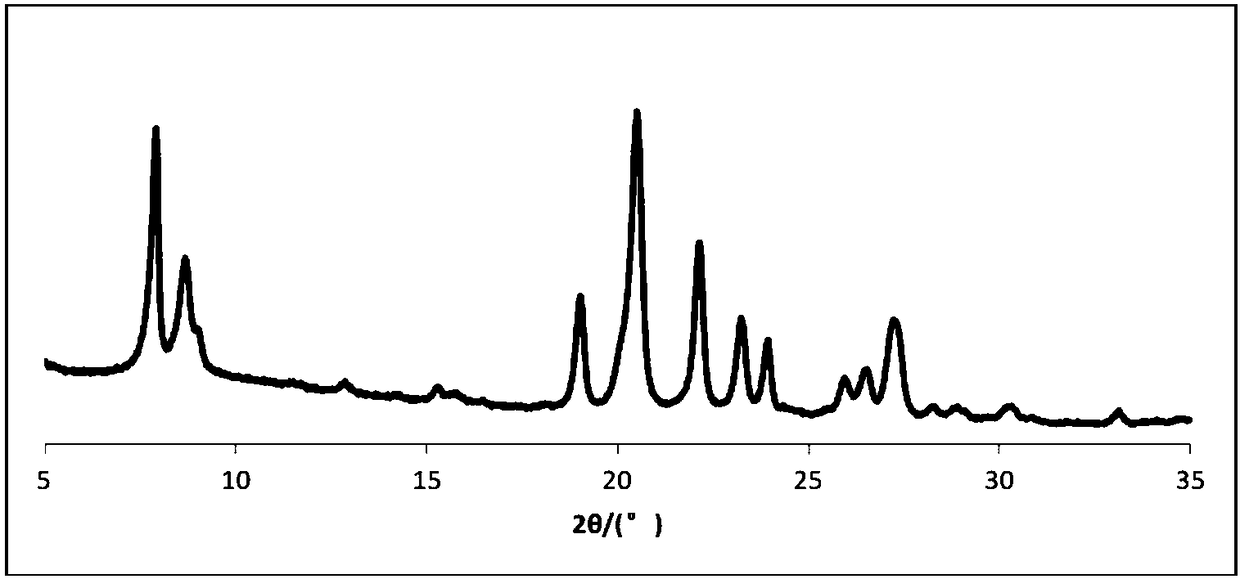

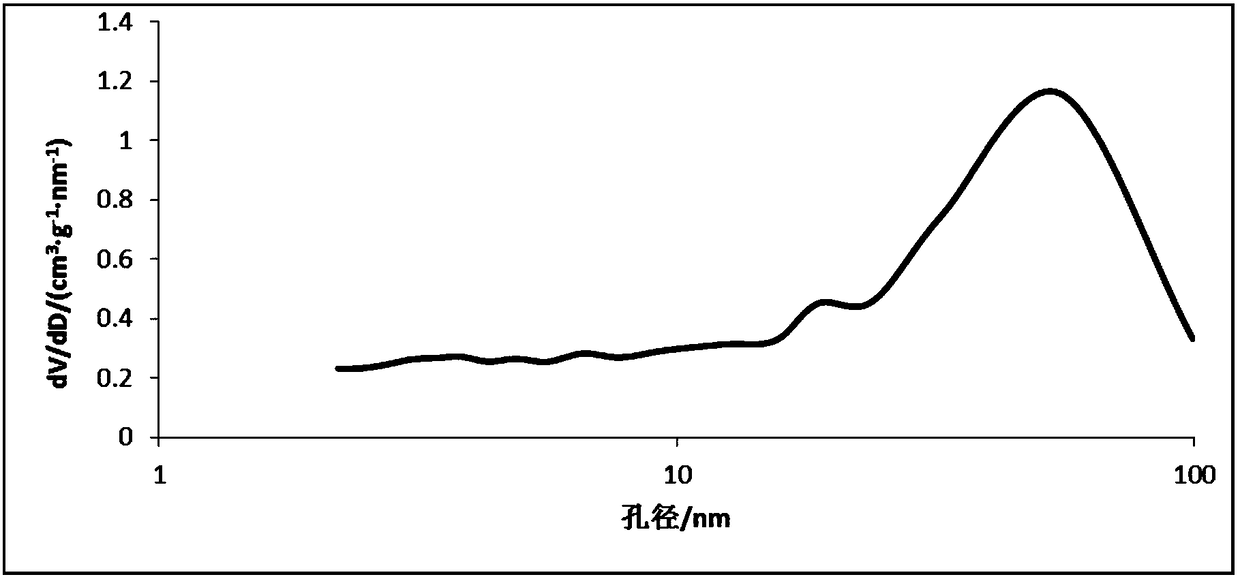

[0048] (1) Preparation of large pore volume EU-1 molecular sieve

[0049] 40g (SiO 2 Content 29 mass %) silica sol is added in 41.19g water, after stirring, add 1.31g sodium aluminate (Al 2 o 3 Content 45% by mass, Na 2 O content 33% by mass), 0.22g of sodium hydroxide, 21.64g of hexammonium trimethyldibromide (97% by mass of purity), 3.56g of hexadecyltrimethylammonium bromide (99% by mass of purity), Stir and mix to obtain reactant evenly, wherein each material mol ratio is as follows:

[0050] 0.3R: 0.05M: 0.05Na 2 O: 0.03Al 2 o 3 : SiO 2 : 20H 2 o

[0051] In the formula, R is hexammonium trimethyldibromide, and M is hexadecyltrimethylammonium bromide.

[0052] Put the above reactants into the reaction kettle, carry out the first-stage hydrothermal crystallization at 110°C under airtight conditions for 18 hours, then raise the temperature to 180°C for the second-stage hydrothermal crystallization for 54 hours, cool to 25°C, collect the solids and wash them thorou...

example 2

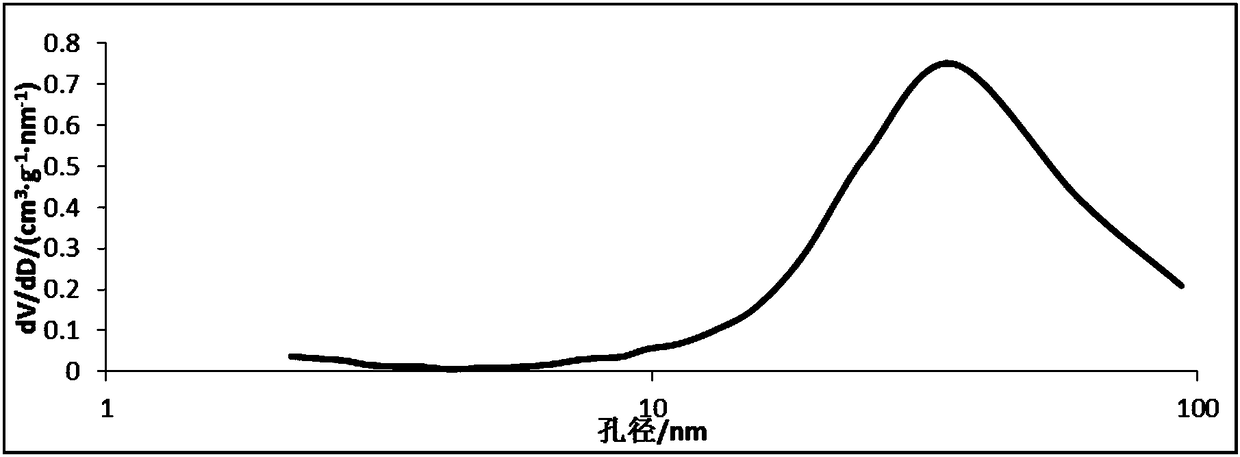

[0058] Catalyst is prepared by the method for example 1, difference is (2) in step, get the carrier 11g of hydrogen-containing type EU-1 molecular sieve, impregnate 24 hours with the solution containing 0.93g boric acid and 6.51g magnesium acetate at 25 ℃, 120 ℃ Drying for 6 hours and calcining at 500° C. for 6 hours prepared Catalyst B, wherein the boron content was 1.5% by mass and the magnesium content was 10% by mass calculated based on the carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com