Cleaning device for floor surface

A technology for cleaning equipment and floors, applied in cleaning equipment, cleaning floors, applications, etc., can solve problems such as easy slipping, difficult dust accumulation structure, difficult to destroy dust structure, etc., to achieve easy removal, reduce slipping, and improve cleaning efficiency and effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

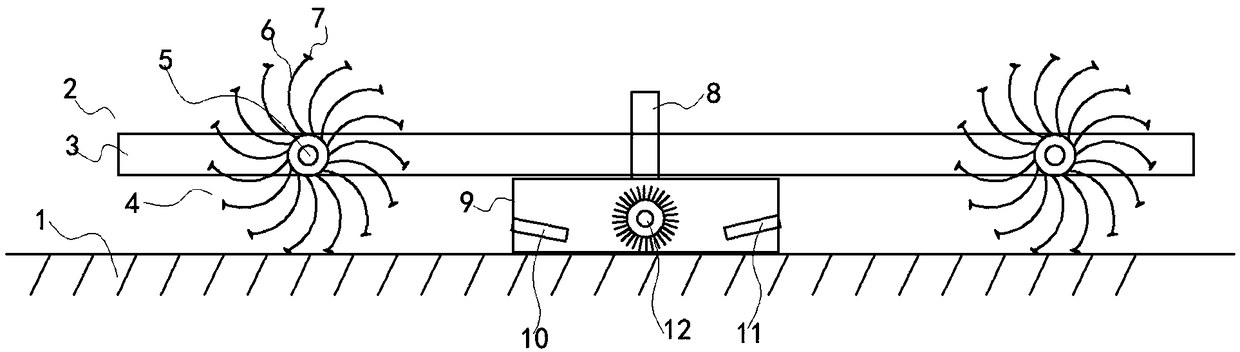

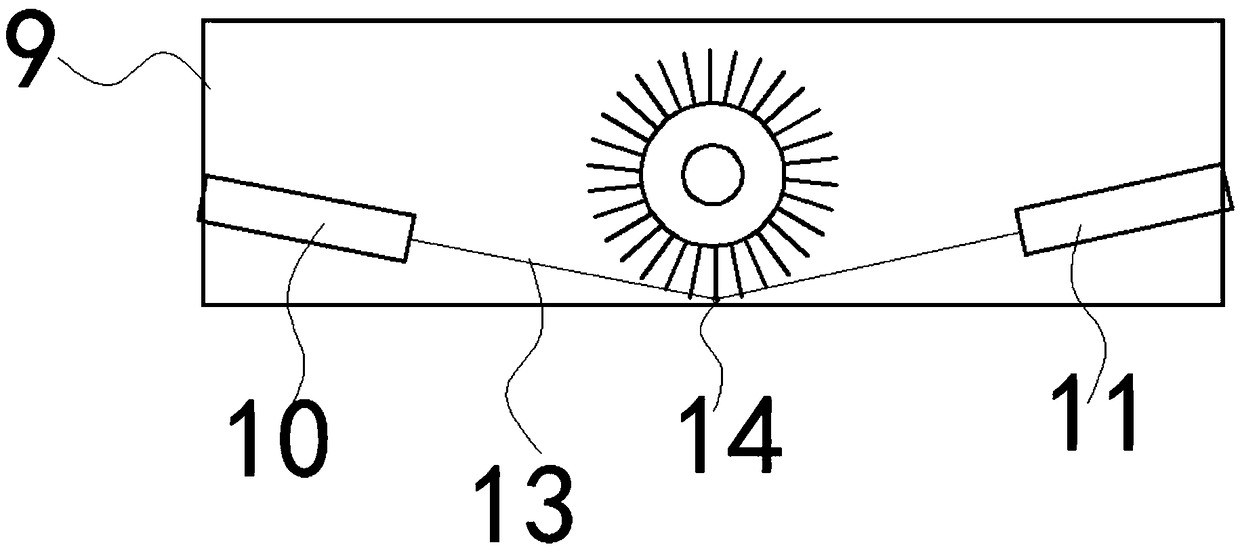

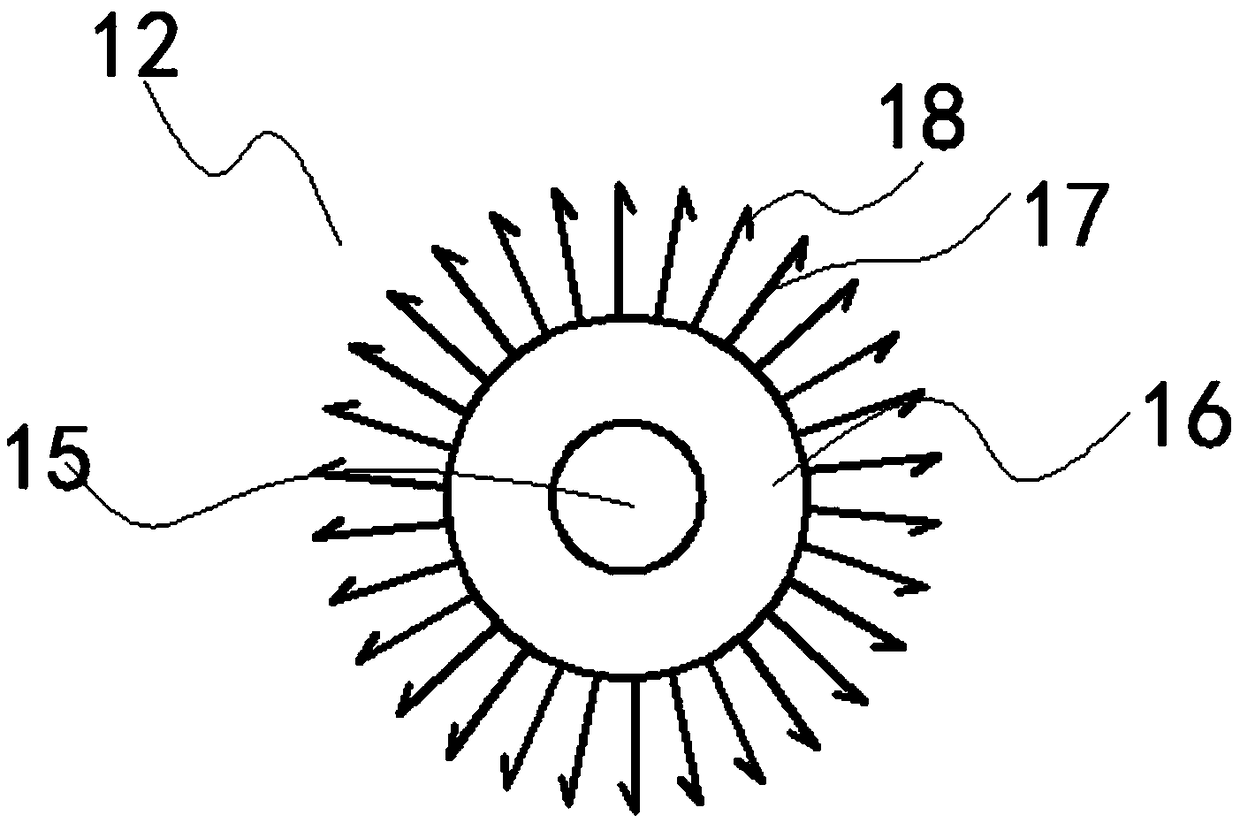

[0029] Such as figure 1 , 2 , 3 and 4, a cleaning device for floor surfaces, comprising:

[0030] The car body 2 that can run along the surface of the floor 1, the car body 2 includes a chassis 3 arranged horizontally and wheels 4 arranged on both sides of the chassis, the wheels 4 support the chassis 3 from the surface of the floor 1 at a certain height distance, The height distance needs to be set according to the size of the cover body 9, so as to be able to set the cover body 9 under the chassis 3, wherein the wheel 4 includes a central shaft 5 and spokes 6, the chassis 3 is erected on the central shaft 5, and the chassis 3 Connect with the central shaft 5 through a bearing so that the central shaft 5 can rotate. The spokes 6 are curved rod-shaped structures. The spokes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com