Buffer type ball valve easy to disassemble and assemble

A technology of easy disassembly and assembly of ball valves, applied in the field of cushioning ball valves, can solve the problems of inconvenient spring removal, spring replacement, and spring damage, etc., and achieve the effect of simple structure, convenient operation, easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

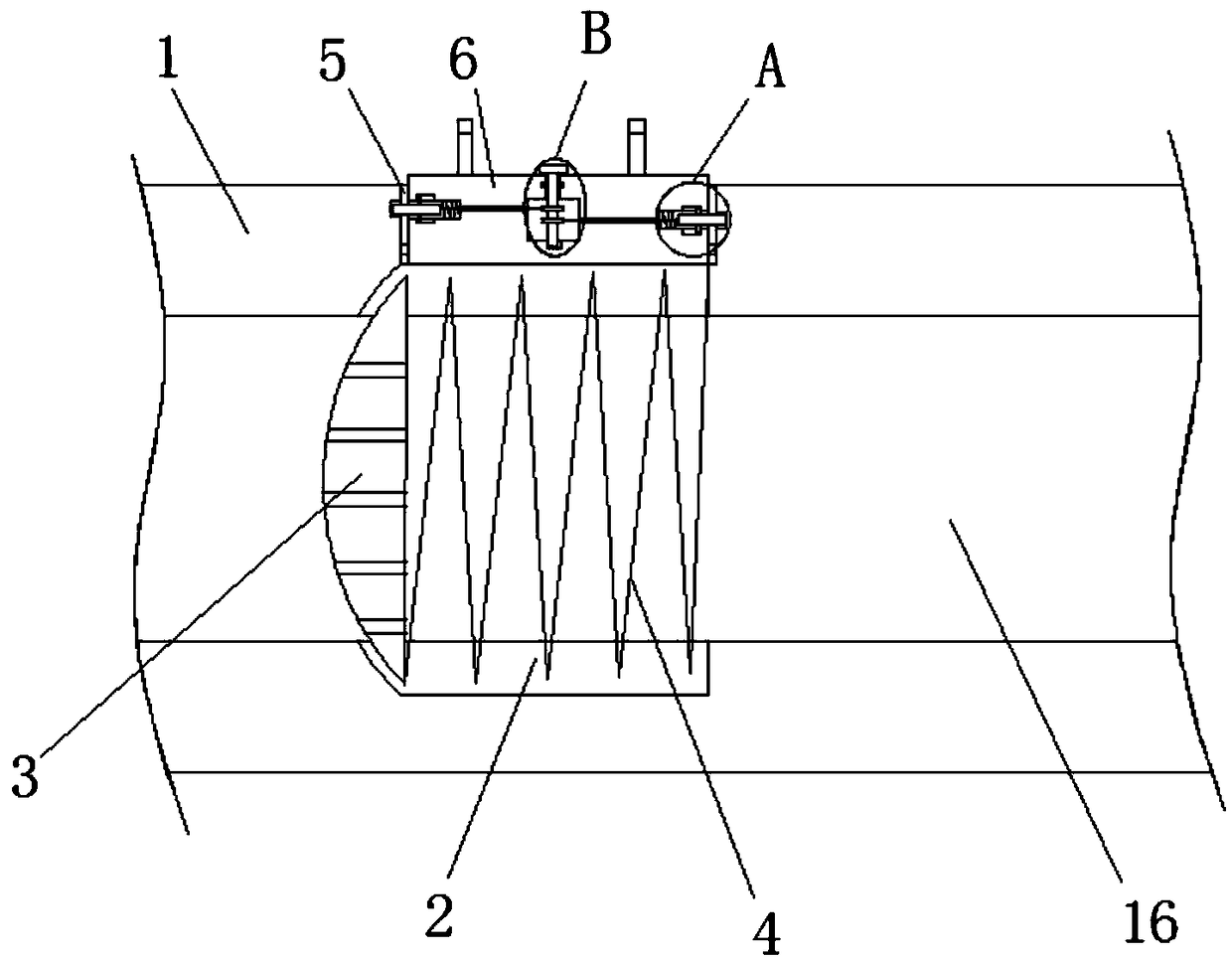

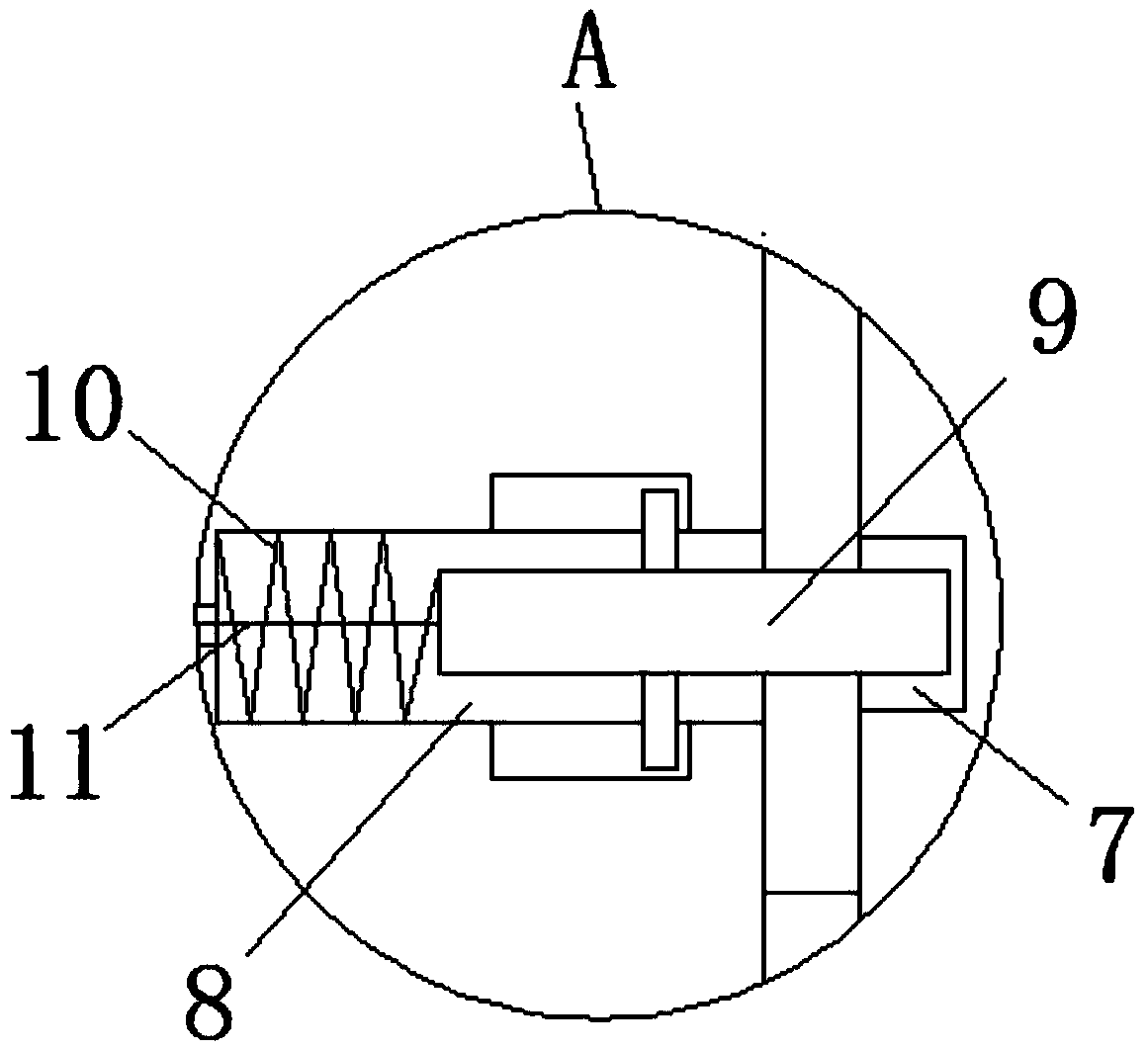

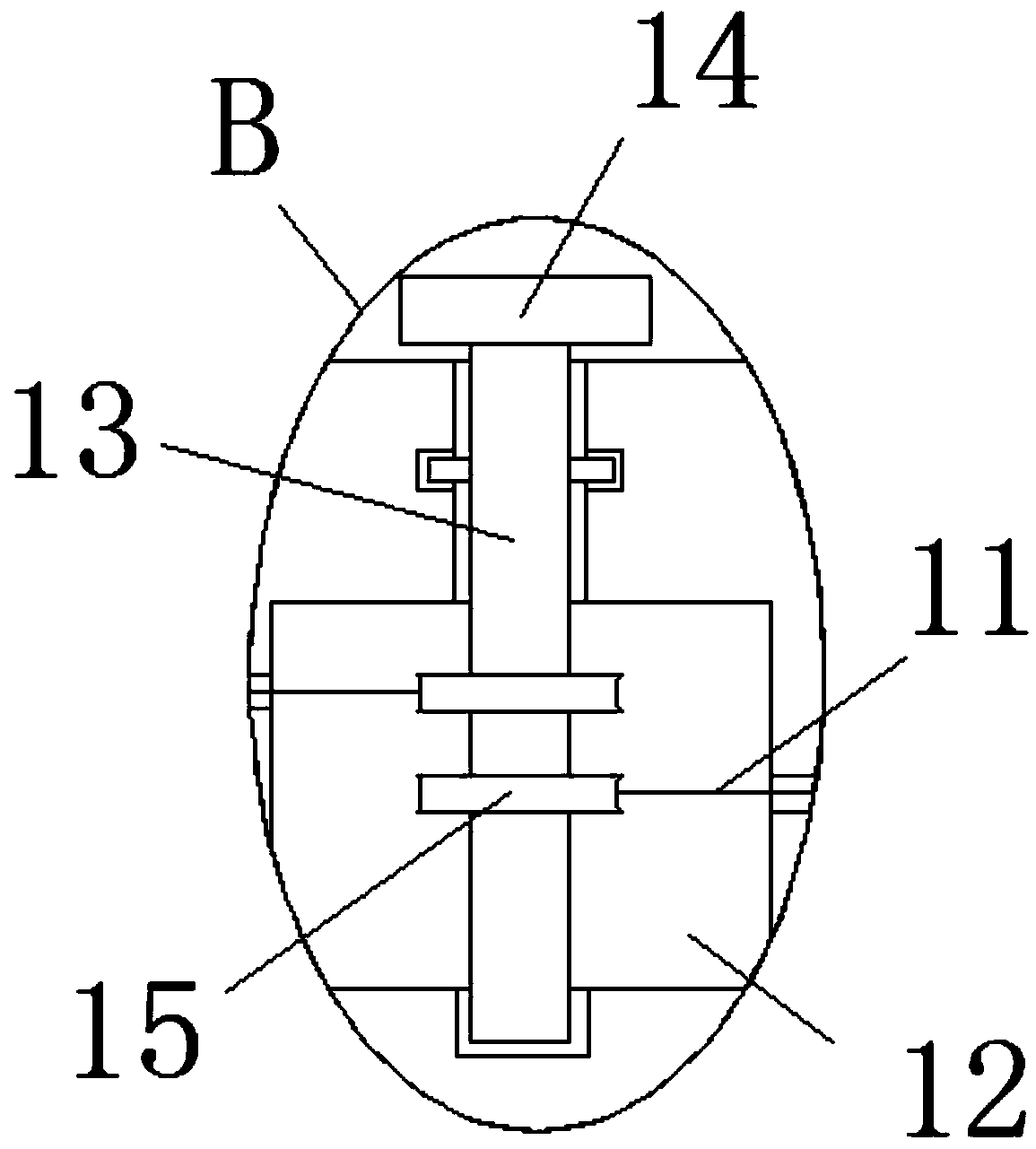

[0020] refer to Figure 1-3 , an easily disassembled buffer type ball valve, including a ball valve seat 1, the ball valve seat 1 is provided with a second communication hole 16, the top inner wall and the bottom inner wall of the second communication hole 16 are provided with a first recess. Slot 2, the same bowl-shaped baffle plate 3 with a through hole is slidably installed in the two first grooves 2, and the same buffer spring 4 is arranged in the two first grooves 2, and one end of the buffer spring 4 is connected to the two One side inner wall of one of the first grooves 2 is in contact with one side, and a first communication hole 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com