Pen holder feeding device

A feeding device and pen holder technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as the lack of recognition and judgment of the pen holder, the complex structure of the hopper under the pen holder, and the inability to guarantee the smooth arrival of the pen holder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

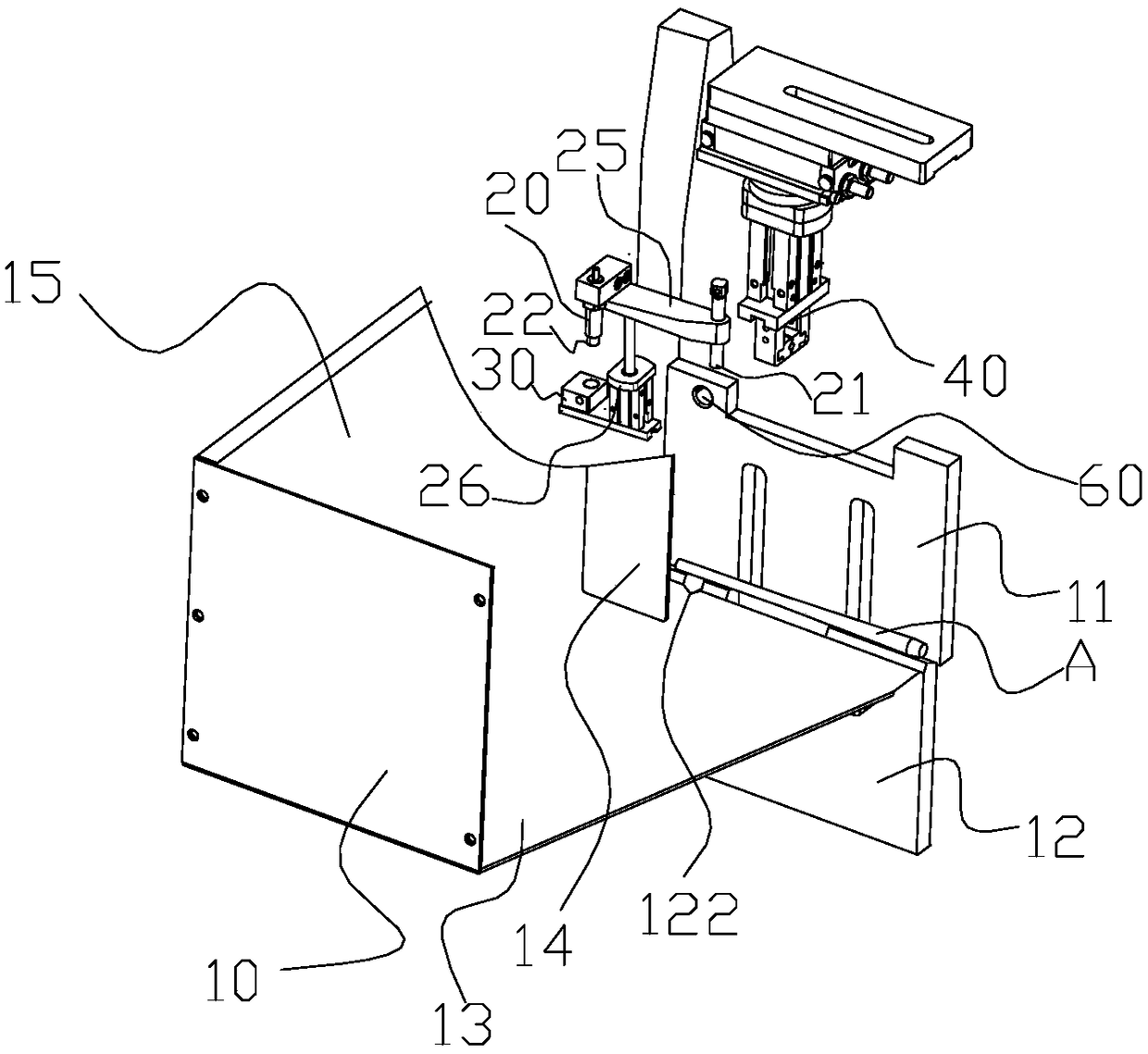

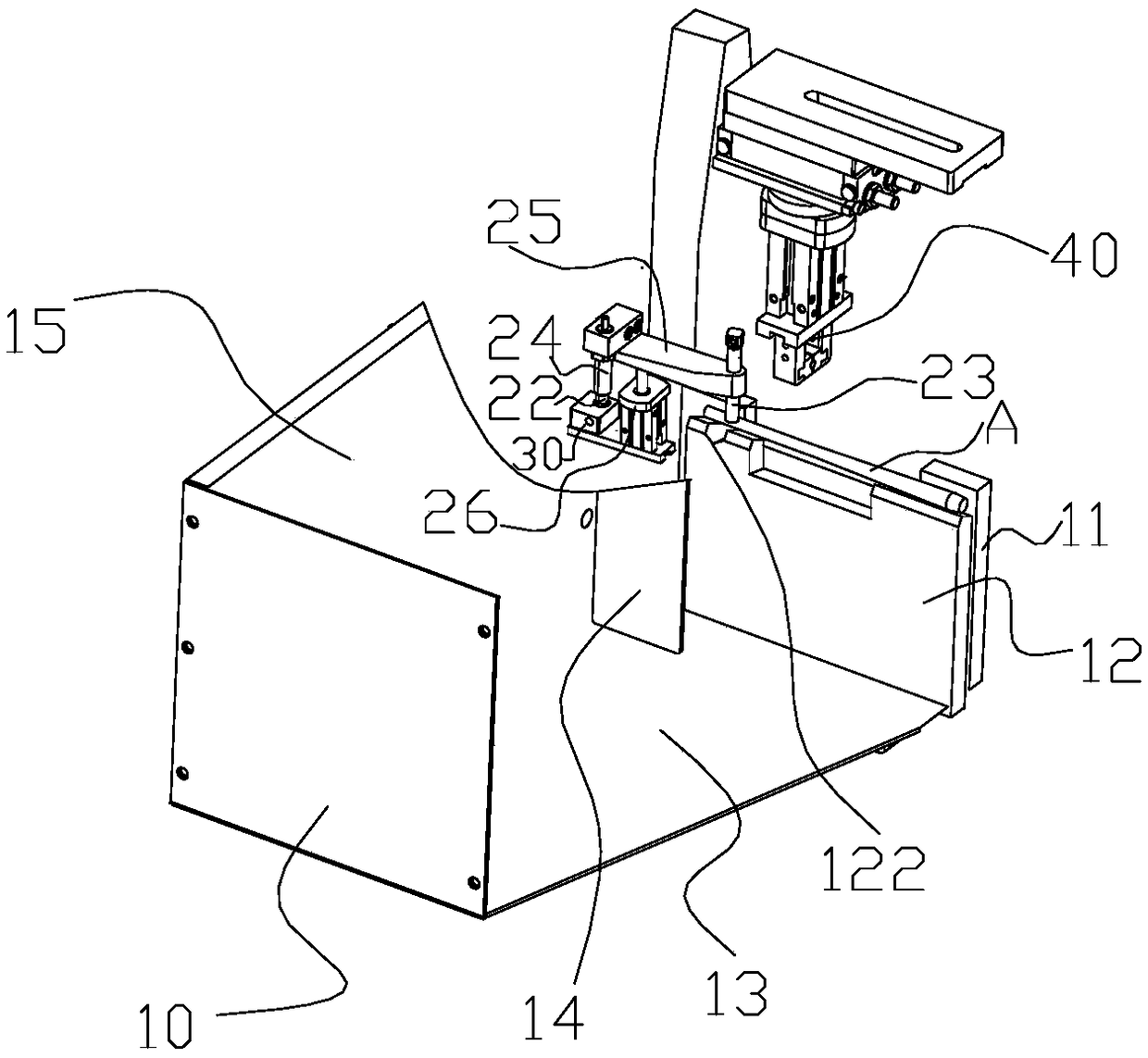

[0009] combine figure 1 , the present invention belongs to the important link in the pen-making machine, and the pen-making machine is exactly to assemble the nib and the pen holder together, except the feeding of the nib, another important aspect is exactly the pen holder feeding device that the present invention relates to, it is used for the horizontal support The supporting part of the pen holder A is a V or U-shaped notch with the notch facing upwards. A vertical displacement pressure head 21 is arranged above the V or U-shaped notch, which is connected with the pressure head 21 and displaced synchronously. A sensor 30 is arranged on the moving path of the contact 22, and the signal collected by the sensor 30 is sent to the controller, and the controller outputs a control signal to the actuator.

[0010] The core of above-mentioned technical scheme is exactly will solve the reliable timely supply of pen holder. Generally speaking, if a craft brush pen has a long pen hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com