Control method of automatic material charging bag applicator

A control method and automatic charging technology, applied in packaging and other directions, can solve the problems of not being well realized, wasting manpower, manual handling, etc., and achieve the effect of good practicability and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

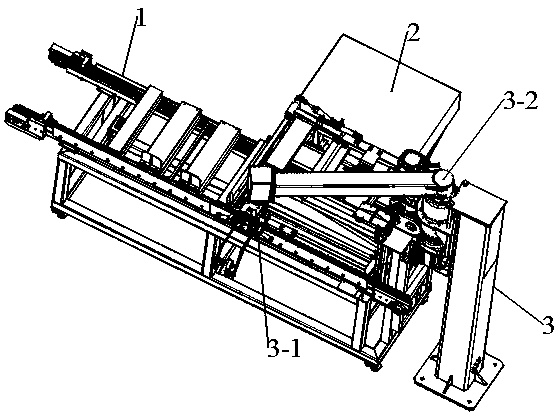

[0041] A control method for an automatic bag-filling machine, which uses a bag-filling machine to pick up and open bags, such as Figure 1-4 As shown, the bag loading and inserting machine includes a conveying mechanism 1, a remaining bag supporting mechanism 2, and a bag taking and opening mechanism 3; the conveying mechanism 1 includes an X-axis conveying device, and the remaining bag supporting mechanism 2 includes a The guide suction bag mechanism 2-3 arranged in parallel with the axis and the Y-axis material supporting device that moves linearly along the Y-axis direction, the packaging bag is placed horizontally on the Y-axis material supporting device; the bag taking and opening mechanism 3 includes a swing arm mechanism 3 -2 and the bag-grabbing manipulator 3-1 arranged on the swing arm mechanism 3-2; the bag-grabbing manipulator 3-1 includes a bag-taking device 3-16 and a bag-opening device arranged sequentially from the inside to the outside.

[0042] The packaging b...

Embodiment 2

[0045] This embodiment is further optimized on the basis of Embodiment 1. The swing arm motor 3-22 of the swing arm mechanism 3-2 drives the swing arm 3-24 to rotate, so that the bag grabbing manipulator 3-24 on the swing arm 3-24 1 is located above the remaining bag holding mechanism 2, the bag taking device 3-16 clamps the side of the packaging bag, and the bag opening device opens the opening of the packaging bag; the swing arm motor 3 of the swing arm mechanism 3-2 -22 drives the swing arm 3-24 to rotate again, and the bag that has been opened by the gripping manipulator 3-1 is moved to the charging mechanism for bagging. The hand grasping rotating motor 3-25 of the swing arm mechanism 3-2 drives the bag grabbing manipulator 3-1 to rotate, so that the side of the packaging bag is between the main fixing clip and the auxiliary fixing clip, and the opening of the packaging bag is located at the opening. Grab between the bag suction cup 3-18 and the fixed disc 3-19 of the bag...

Embodiment 3

[0050] This embodiment is further optimized on the basis of embodiment 1 or 2, as Figure 12-15 As shown, the bag grabbing manipulator 3-1 includes a fixed mount 3-11, a driving mechanical arm, a mechanical connecting rod, a first driving device 3-12, a mechanical connecting rod, a bag taking device 3-16 and a bag opening device, The fixed mounting base 3-11 is slidingly connected with the horizontal sliding base 3-26; the first driving device 3-12 is hingedly mounted on the fixed mounting base 3-11, and the driving mechanical arm includes main parts that form a jaw with each other. linkage arm 3-13, auxiliary linkage arm, the driving rod of the first driving device 3-12 is hinged with the main linkage arm 3-13, and the driving rod of the first driving device 3-12 is connected with the auxiliary linkage arm through a mechanical linkage Hinged, the first driving device 3-12 drives the main linkage arm 3-13 and the auxiliary linkage arm to open and close; the bag taking device 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com