Waxdip based walnut freshness retaining method and complete equipment

A processing method and technology for walnuts, which are applied in food processing, heating preservation of seeds, and seeds preservation by coating a protective layer, etc., can solve the problem that the walnut preservation treatment technology is not simple, environmentally friendly, economical, efficient, and difficult to achieve the expected preservation effect, etc. problem, to achieve the effect of high temperature sterilization and wax soaking time control, ensuring freshness and taste, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

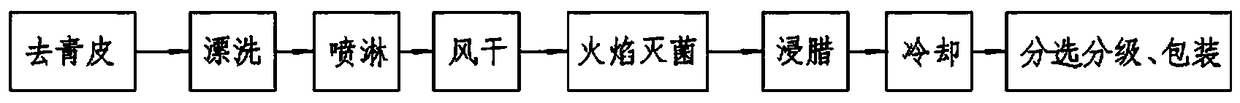

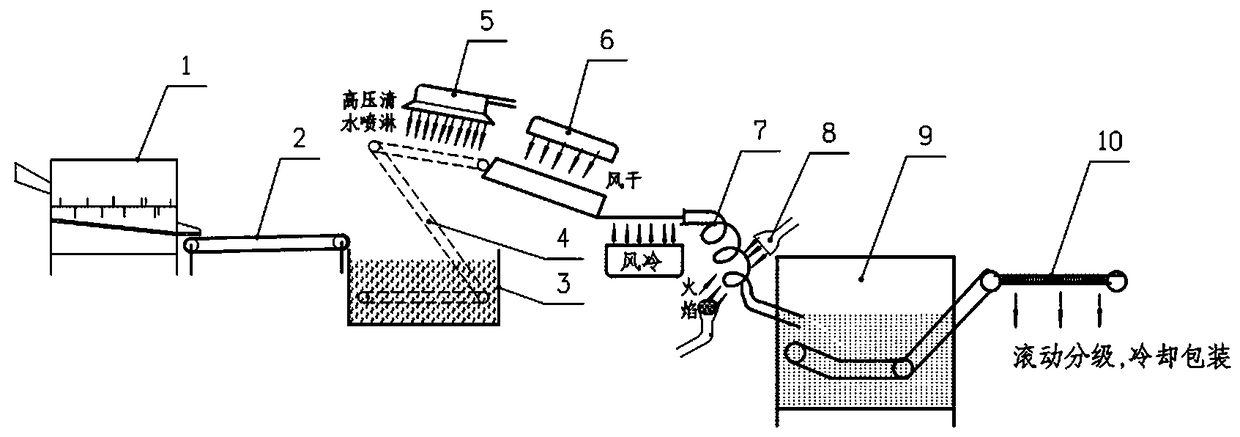

[0020] see figure 1 , the fresh-keeping treatment method of walnut soaked in wax according to the present invention, after the mature walnuts are picked, the peeling treatment is carried out manually or mechanically, and then rinsing and air-drying are carried out in time, and the walnuts after the rinsing and air-drying are sterilized by flame method, and the flame sterilized During the process, the speed of the material is controlled and the material is rolled so that the walnuts quickly pass through the flame zone. The sterilization temperature in the flame zone is controlled at 800-900 degrees, and the sterilization time is 3-6 seconds; after sterilization, it enters the wax pool for waxing treatment. Then air cool down.

[0021] The walnuts can be well kept fresh by adopting high-temperature flame instant sterilization and soaking in wax. At room temperature, fresh walnuts can be preserved for more than 180 days. Energy saving and environmental protection, enabling cons...

Embodiment 2

[0023] see figure 1 , the walnut dipping wax fresh-keeping treatment method of the present embodiment is different from Embodiment 1 in that: further, the walnuts after flame sterilization enter the wax pond, the temperature of the wax pond is controlled at 85-95 degrees, and the wax dipping time is controlled at 3-8 seconds, use 58-62° food-grade refined paraffin wax, immediately air-cool the walnuts out of the wax pool, and carry out grading treatment while air-cooling and cooling. Grading is graded by diameter. After grading, it is packaged and put into storage according to the level.

Embodiment 3

[0025] see figure 1 , the walnut dipping wax fresh-keeping treatment method of the present embodiment, differs from embodiment 1 in that: the walnuts after the green peeling treatment are soaked in an aeration tank for 2 to 3 minutes, and then rinsed with high-pressure water spray, and the walnuts after rinsing Perform air-drying treatment, and sterilize in time after cooling down to room temperature. The air-drying process adopts natural air-drying or artificial physical air-drying; artificial physical air-drying temperature is 70-85 degrees, wind speed is 4-6 m / s, and air drying time is 30-60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com