Electronic heating device and heating method

An electronic heating and heating module technology, which is applied in the field of electronic cigarettes, can solve the problems of low peripheral temperature, insufficient baking of cigarettes, and high center temperature, and achieve the effects of energy saving, sufficient baking, and uniform release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

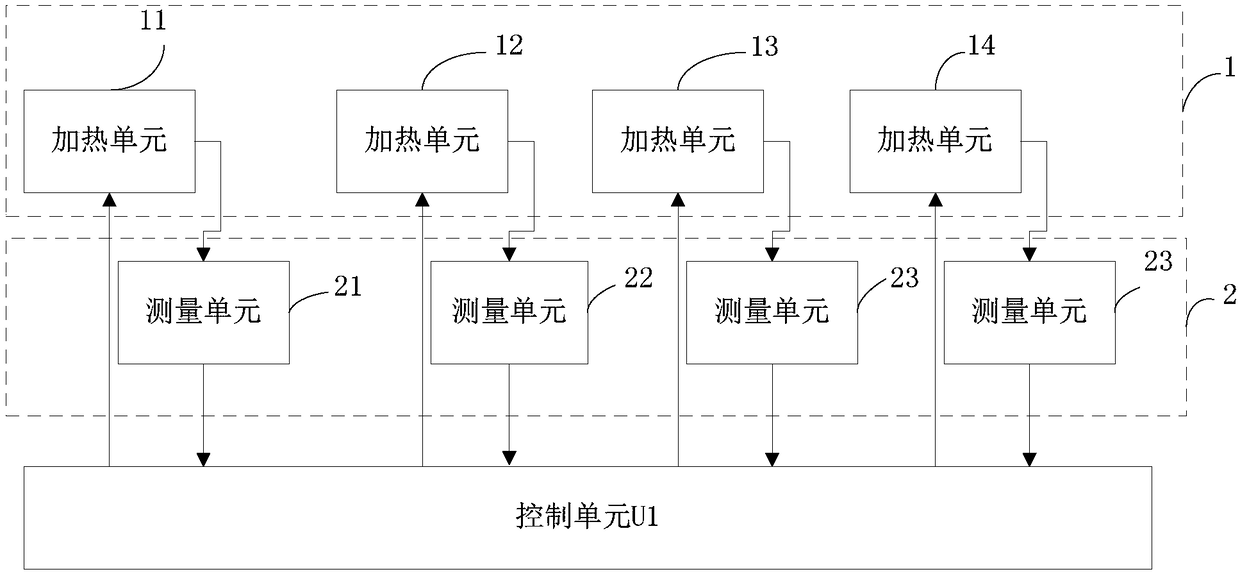

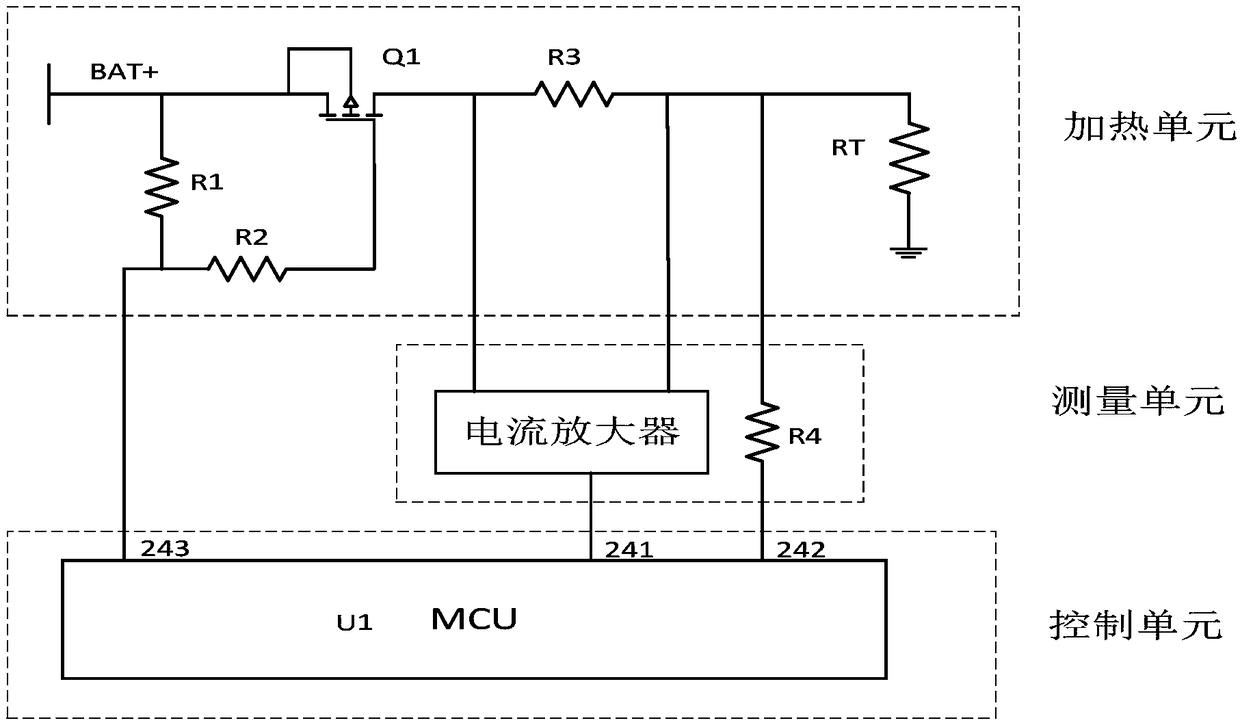

[0034] Such as figure 1 As shown, this embodiment provides an electronic heating device, which includes a control unit U1, a heating module 1 and a measurement module 2; wherein, the control unit U1 is used to output a control signal to drive the heating unit to work or shut down; the heating module 1 It is used to heat the cigarette; the measurement module 2 is used to collect the voltage and current information of the heating unit, convert the voltage and current into resistance value information, and transmit it to the control unit U1 for the control unit U1 to adjust the control signal and drive the heating module to work When the voltage and current are kept within the allowable range of the control unit U1.

[0035] The heating module is used to heat and bake the cigarettes without burning the cigarettes, and the cigarette flavor and smoke are released by the baking to be smoked by the smoker, thereby reducing the harm of tar and harmful substances to the human body.

...

Embodiment 2

[0097] In this example, if Figure 5 As shown, the number of measuring units in the measuring module 2 is one, that is to say, the measuring unit is also the measuring module 2 . The four heating units (11, 12, 13, 14) jointly measure the average temperature of the heating element RT through the measurement module 2, and each heating unit (11, 12, 13, 14) is controlled by a temperature value, and the temperature The value comes from the average temperature value of the heating element RT jointly measured by the four heating units (11, 12, 13, 14).

[0098] The heating process of the heating element, the control process of the control unit U1, the design structure of the heating unit and the design mechanism of the measurement unit are all consistent with those in the embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com