Method for solving wrinkle of dried separator of lithium ion battery

A lithium-ion battery and diaphragm wrinkle technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems that affect the large-scale use of dry-process diaphragms, increase the cost of battery production, and cannot eliminate wrinkles in time, and achieve the goal of processing The effect of wide selection of solvents, low investment in equipment, and wide selection of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

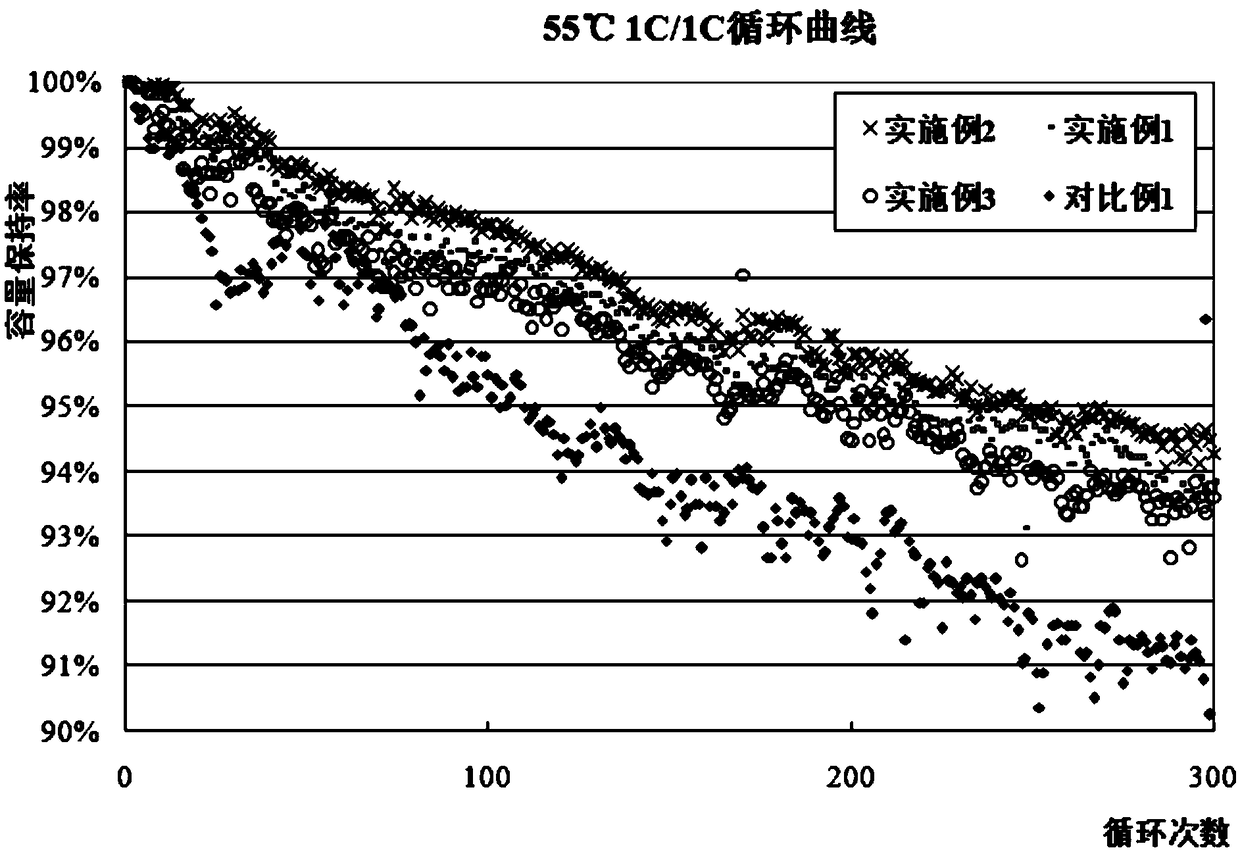

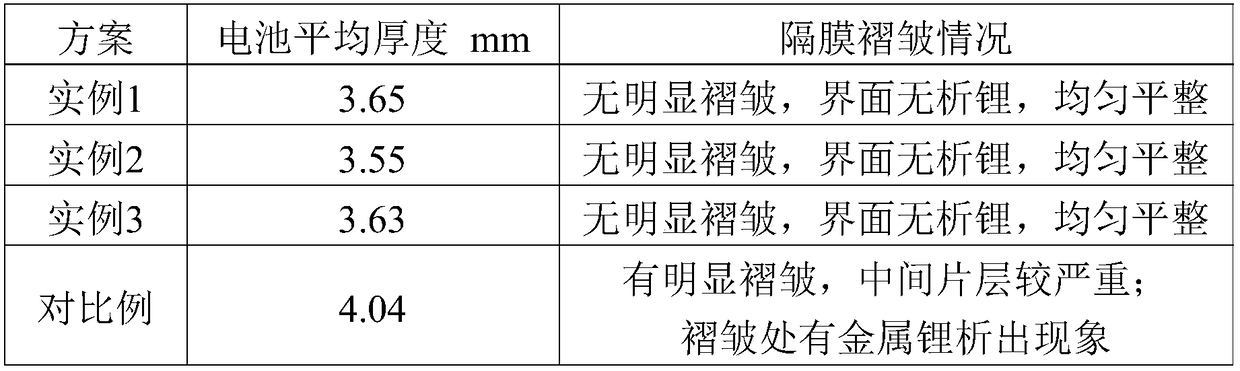

Embodiment 1

[0036] A method for solving the wrinkles of the lithium-ion battery dry-method diaphragm, including the following steps: pour ethyl methyl carbonate into a treatment tank, the treatment tank has a width of 3m, a length of 8m, and a depth of 3m, and maintains the temperature of the treatment pool at 70°C and the height of the liquid level 2m, the diaphragm is made of PP uniaxially stretched film with a thickness of 16μm; in the solvent treatment process, before the diaphragm is slit, the state of the diaphragm is treated as a parent roll, the diaphragm is immersed in ethyl methyl carbonate, and the diaphragm is passed at a speed of 10m / min In the treatment tank, the total treatment time is 3 minutes, and then it is dried at a drying temperature of 100°C. After the diaphragm is dried and rolled, it is cooled and allowed to stand for 12 hours, and finally cut.

[0037] The battery cathode material selects nickel cobalt lithium manganate ternary cathode material, the conductive agent ...

Embodiment 2

[0040] A method for solving the wrinkles of lithium-ion battery dry-method separators, including the following steps: pour ethyl methyl carbonate and dimethyl carbonate (the mass ratio of ethyl methyl carbonate to dimethyl carbonate is 1:1) The treatment tank has a width of 3m, a length of 8m, and a depth of 3m. The treatment tank is maintained at 70°C and 2m. The membrane is made of PP uniaxially stretched film with a thickness of 16μm. The solvent treatment process is before the separation of the membrane. The processing membrane is in the mother roll. The diaphragm is immersed in ethyl methyl carbonate, and the diaphragm is passed through the treatment tank at a speed of 10m / min for a total treatment time of 3 minutes, and then dried at a drying temperature of 100°C. After the diaphragm is dried and rolled, it is cooled and left for 12 hours. Finally, slitting.

[0041] The formula and preparation method of the positive electrode and the negative electrode of the battery are t...

Embodiment 3

[0043] A method for solving the wrinkles of lithium-ion battery dry-method separators, including the following steps: pour ethyl methyl carbonate and dimethyl carbonate (the mass ratio of ethyl methyl carbonate to dimethyl carbonate is 1:1) Cell, treatment cell width is 0.5m, length is 1m, depth is 1m, and the treatment cell is maintained at 80℃ and the liquid level is 0.5m. The diaphragm is made of PP uniaxially stretched film with a thickness of 16μm. The solvent treatment process is before the battery zigzag laminate , Process the diaphragm as a finished roll, immerse the diaphragm in ethyl methyl carbonate, and make the diaphragm pass through the processing tank at a speed of 40m / min. The total processing time is 45s, and then it is dried at a drying temperature of 90℃, and it is taken out of the oven for Z The font stack is available.

[0044] The formula and preparation method of the positive electrode and the negative electrode of the battery are the same as in Example 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com