Solar product packaging method and system

A packaging method and solar energy technology, applied in the direction of layered products, chemical instruments and methods, lamination devices, etc., can solve problems affecting product quality, poor product lamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, the laminator is the main equipment in this embodiment. Based on this laminator, continuous lamination in stages is realized.

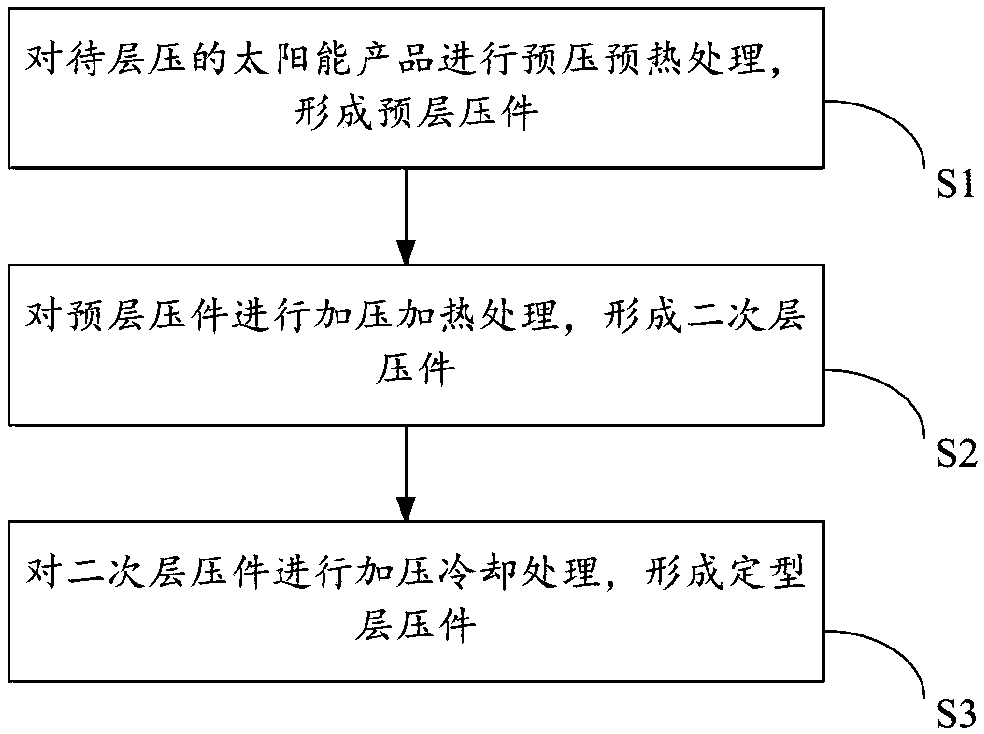

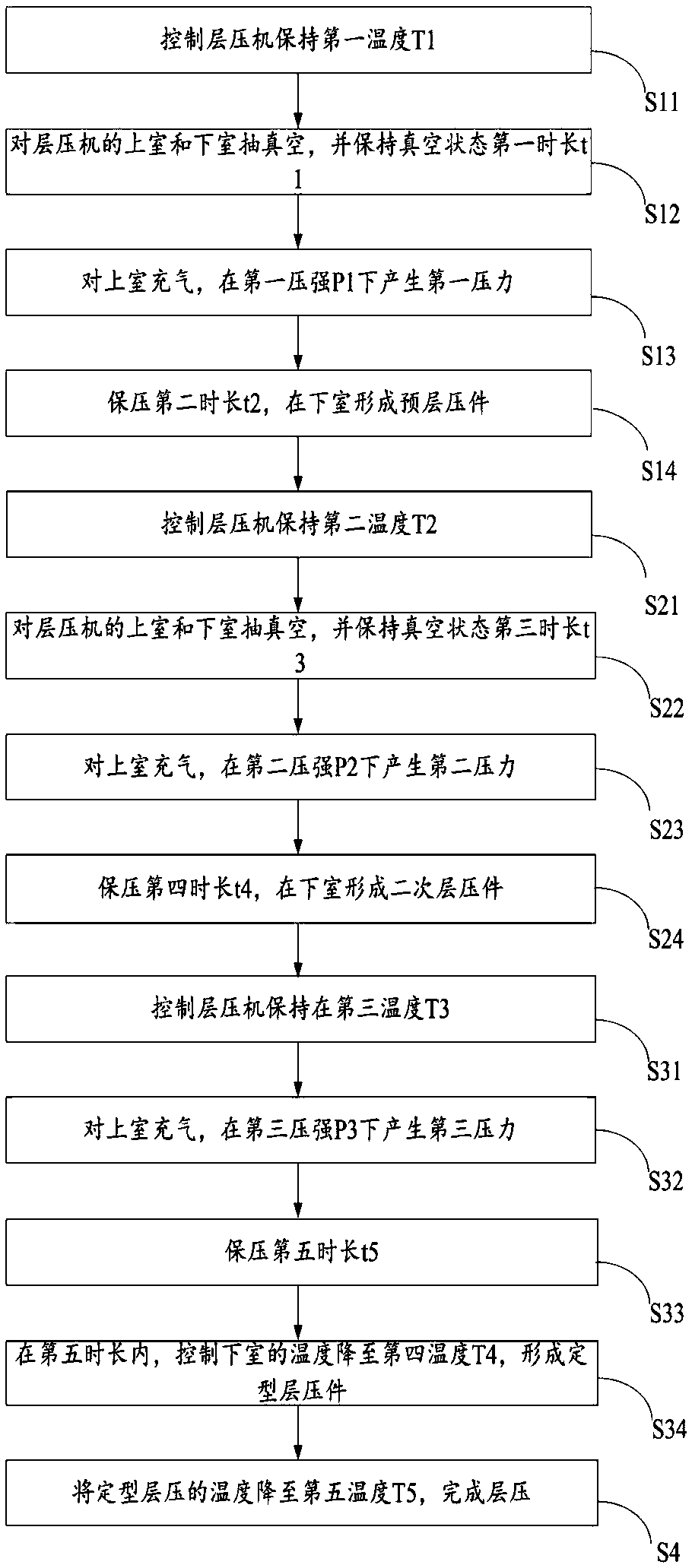

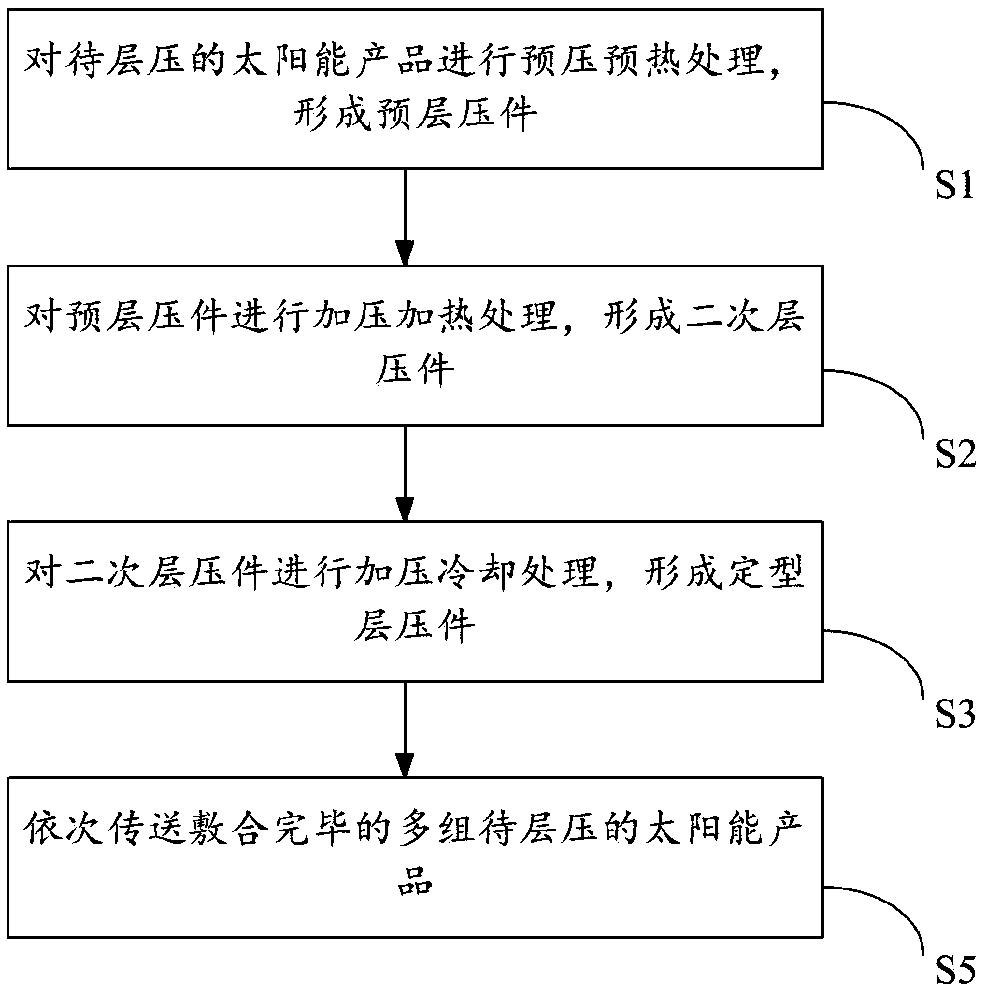

[0020] see figure 1 , the present embodiment provides a solar product packaging method, comprising:

[0021] Step S1: pre-pressing and pre-heating the solar products to be laminated to form a pre-laminate.

[0022] The chamber of the laminator used in this step is defined as the first chamber, and the first-level lamination of the solar products to be laminated can be performed in the first chamber. During this process, the heating temperature is controlled to be the preliminary heating temperature , so as to facilitate the preheating of the solar products to be laminated; the pressure of extruding the solar products is controlled to a preliminary extrusion pressure, so as to facilitate the pre-compression of the solar products to be laminated. The preheating and prepressing in this step is beneficial to the structure of d...

Embodiment 2

[0098] see Image 6 , this embodiment provides a solar energy product packaging system, including a first-level laminator 10, a second-level laminator 20, and a third-level laminator 30 connected in sequence by automatic transmission equipment; the lower part of the third-level laminator 30 The chamber is connected with water cooling equipment.

[0099] see Figure 7 , preferably, each level of laminator can be the same type of laminator, and the laminator includes an upper machine cover 100 and a lower base 200, and the upper machine cover 100 and the lower base 200 are opened and closed by a drive mechanism 300 such as a hydraulic or pneumatic lifting device. Cover action, the automatic conveying equipment can transfer the product to be processed to the lower base 200, after the product to be processed is placed, the upper machine cover 100 completes the cover action, and a closed space is formed between the upper machine cover 100 and the lower base 200, that is In the af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com