Novel evaporator process detecting and debugging system for nuclear fuel processing plant

A process detection and debugging system technology, applied in nuclear engineering, program control in sequence/logic controllers, instruments, etc., can solve the problems of slow feedback of the adjustment control loop, difficulty in judging the state of the instrument, and unfavorable timely adjustment, etc. The effect of shortening the adjustment cycle, improving the transmission accuracy and efficiency, and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the drawings and embodiments.

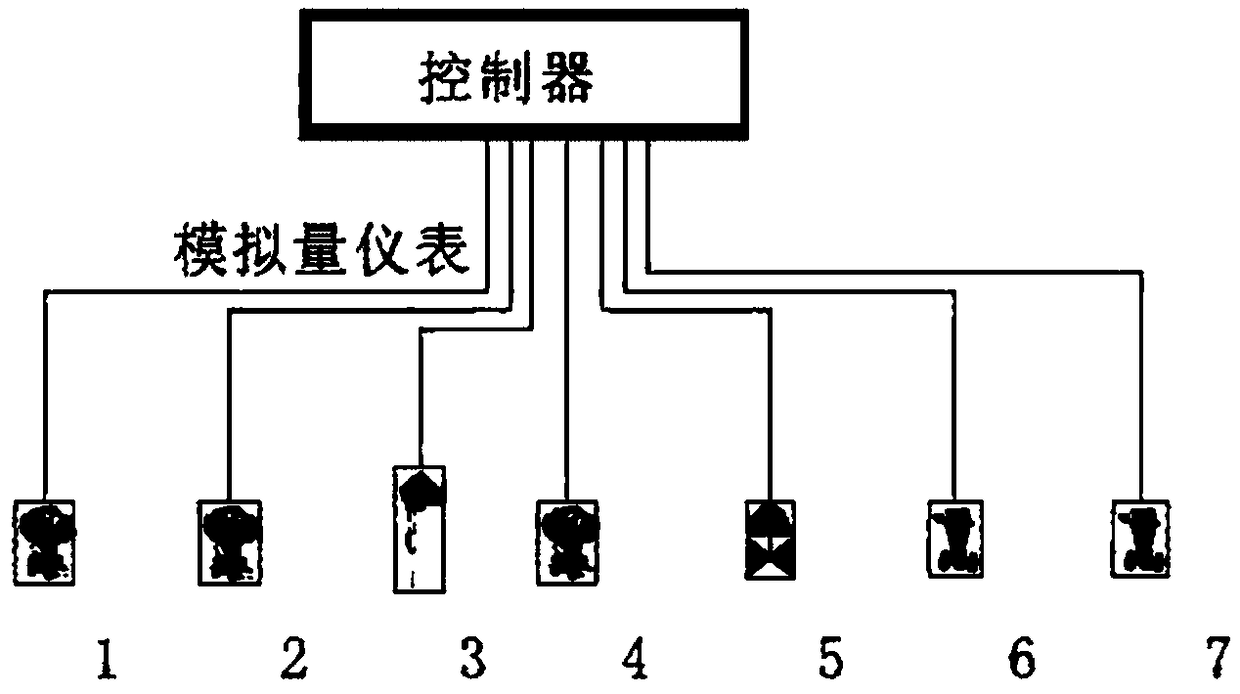

[0036] Such as image 3 As shown, the present invention provides a new type of nuclear fuel reprocessing plant evaporator process detection and debugging system, including a controller and instrumentation equipment; the instrumentation layer equipment is connected to the controller through the Foundation Fieldbus. The instrumentation equipment includes a density measuring instrument 2, a liquid level measuring instrument 1, a temperature measuring instrument 3, a pressure measuring instrument 4, a steam inlet switching valve 5, a steam inlet regulating valve 6 and an evaporator feeding device 7.

[0037] Specifically, the liquid level measuring instrument 1, the density measuring instrument 2 and the evaporator feeding device 7 share a foundation field bus to connect to the controller, so as to realize the FF bus type intelligent differential pressure change The transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com