A method for extracting flow characteristics of burner air distribution baffle from boiler operation data

A boiler operation and burner technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of high labor intensity, many working conditions of furnace cold ventilation test, time-consuming and labor-intensive, etc., to achieve high labor intensity , saving ignition start-up time and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

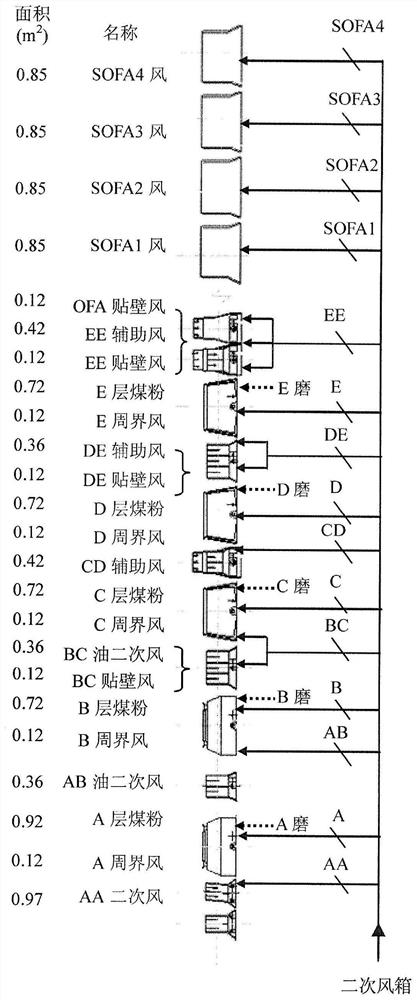

[0102] A 300MW tangential combustion pulverized coal boiler adopts a direct blowing pulverization system and is equipped with 5 medium-speed coal mills. The primary air from the outlet of the same coal mill is distributed to 4 fuel nozzles on the same floor. There are 5 floors in total. 20 fuel nozzles, from bottom to top, the fuel nozzles are recorded as layers A, B, C, D, E; there are 19 layers of air nozzles, 4 in each layer, a total of 76; the 19 layers of air nozzles are divided into 6 categories: ① AA layer secondary air, located at the bottom; ② Auxiliary secondary air: a total of 3 layers, respectively CD, DE and EE layer secondary air; ③ oil gun secondary air: a total of 2 layers, respectively AB, BC layer oil Gun secondary air; ④ fuel nozzle perimeter secondary air: a total of 5 layers, namely A perimeter wind, B perimeter wind, C perimeter wind, D perimeter wind, E perimeter wind, ⑤ wall-attached secondary air, a total of 4 layers, respectively BC, DE, EE, and OFA l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com