Distributed collaborative optimization control test platform

A technology of collaborative optimization and control experiment, applied in the direction of program control, computer control, general control system, etc., can solve the problem of lack of thinking and design of distributed chemical network, and achieve the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

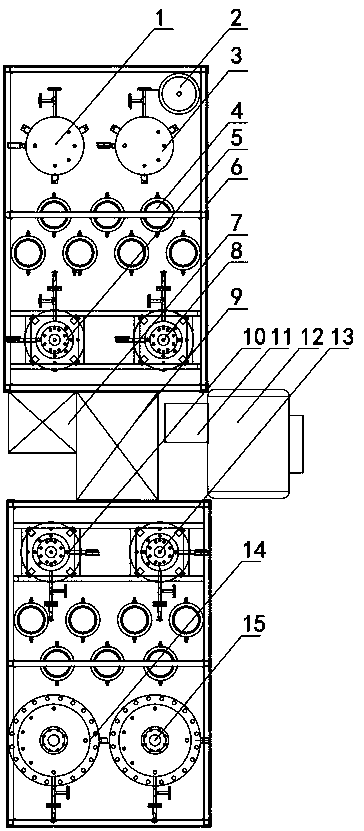

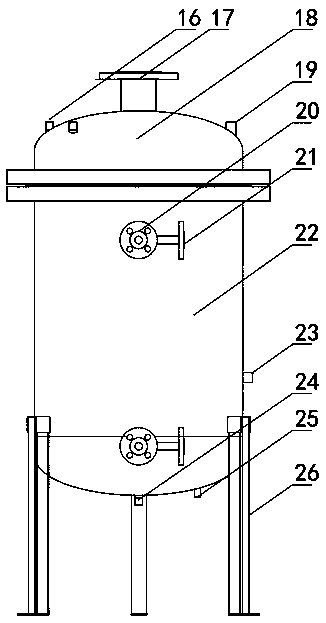

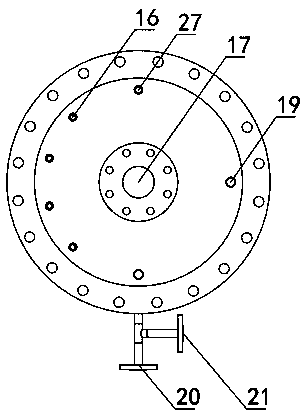

[0049] Figure 1~8 It is the best embodiment of the present invention. Figure 1~8 The present invention will be further explained.

[0050] Such as figure 1 As shown, a distributed collaborative optimization control test platform includes test areas on both sides and a control area between the test areas. An industrial control cabinet 7, a main cabinet 9 and an air compressor 11 are sequentially arranged in the control area from front to back, and a water heater 12 is also arranged behind the air compressor 11. The control system of the distributed collaborative optimization control test platform is set in the main cabinet 9, and the control system also includes the test area on both sides and the upper computer (not shown in the figure) outside the control area.

[0051] A first reactor 5 and a second reactor 8 are arranged on the inner side of the test area on the left side of the control area in turn from front to back. A number of pneumatic valves 4 are arranged on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com