Large-size drop hammer impact device

A drop-weight impact, large-scale technology, applied in measuring devices, impact tests, instruments, etc., can solve the problems of insufficient refinement of drop-weight testing machines, difficulty in meeting impact test requirements, and small size of drop-weight testing machines. Inefficiency of manual operation, preventing secondary impact, and ensuring the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

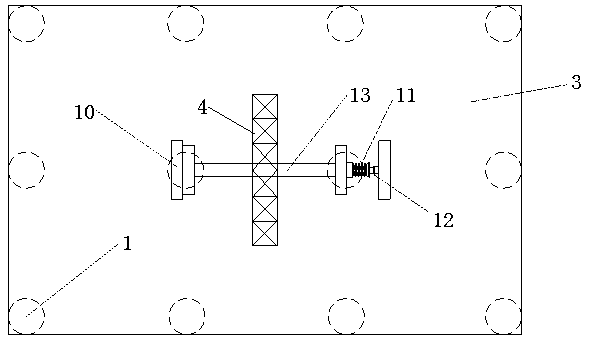

[0013] First of all, it should be noted that the accompanying drawings are for more vivid, concise and clear display of the present invention, and therefore cannot be used as a limitation to the present invention, and construction personnel skilled in the art may make appropriate changes and modifications according to actual conditions.

[0014] Below in conjunction with accompanying drawing, structure of the present invention and specific embodiment will be further described:

[0015] A large-scale drop hammer impact device according to the present invention includes a pile foundation (1), a cap (2), a rigid platform (3), a lattice-type rigid support (4), a high-precision guide rail (5), a drop Hammer (6), counterweight (7), anti-rebound secondary impact system (8), excitation device (9), rigid wall (10), butterfly spring (11), jack (12), test specimen ( 13), sensor (14).

[0016] The pile foundation (1) and the cap (2) are connected as a whole, and the cap (2) is used as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com