Cooling tower water accumulation tank convenient to clean

A water storage tank and cooling tower technology, applied in the field of cooling towers, can solve problems such as refrigeration equipment shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

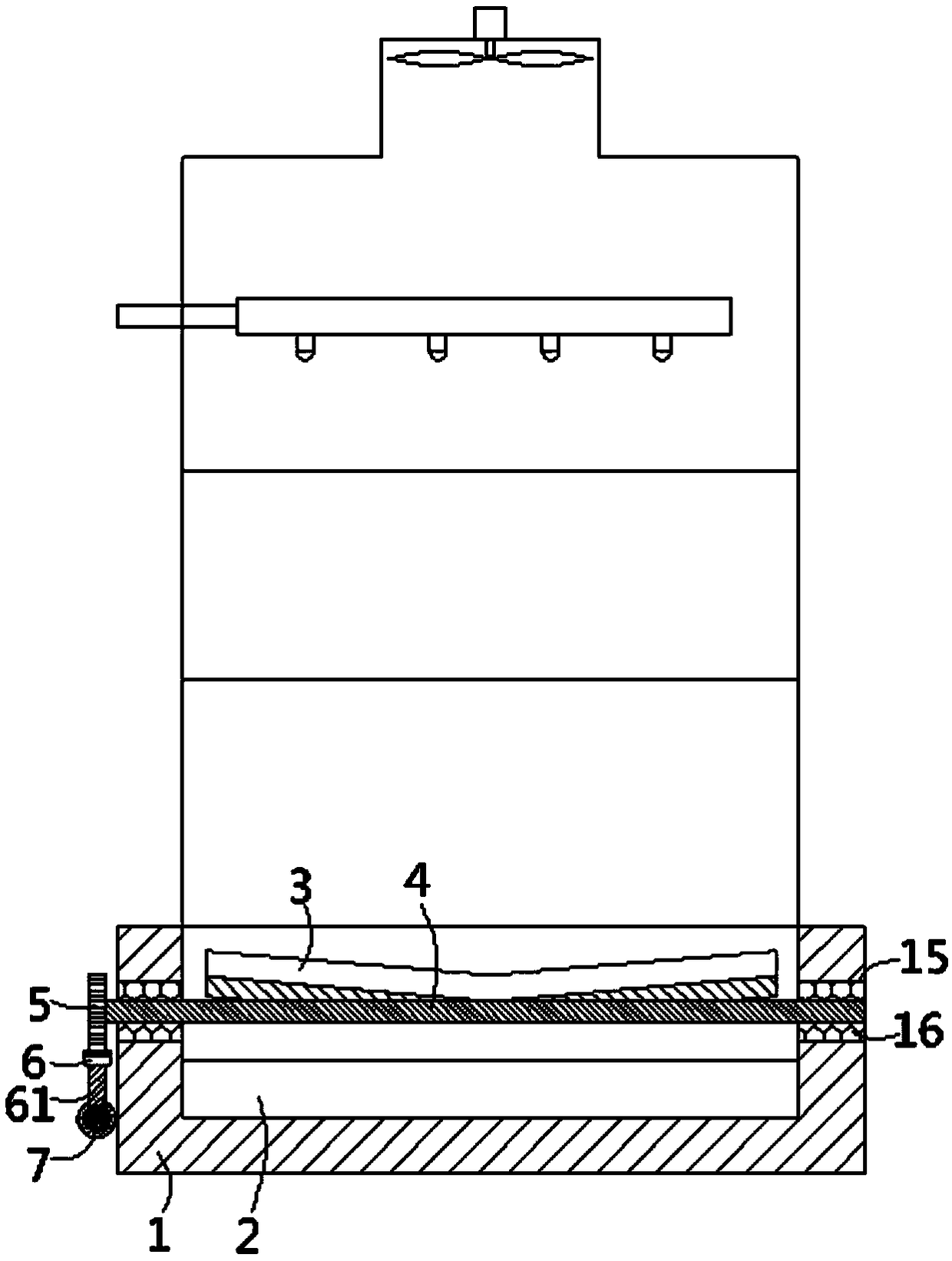

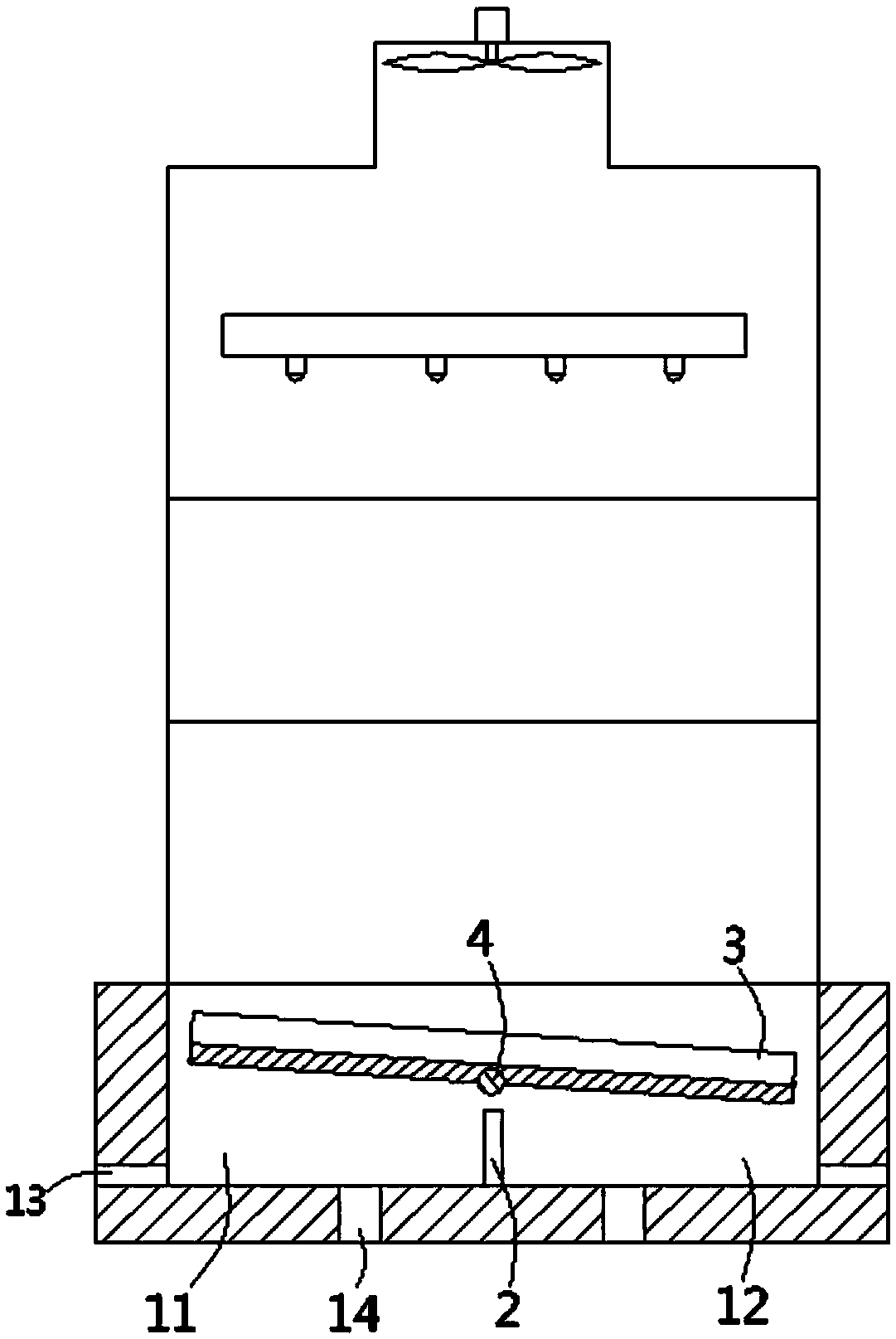

[0024] see figure 1 , figure 2 , Image 6 , Figure 7 According to the present invention, a cooling tower pond that is convenient for cleaning includes a pool 1 and a partition 2 arranged in the pool, and the partition 2 separates the pool 1 into a first pool 11 and a second pool 12. The side walls of the first pool 11 and the second pool 12 are provided with a water outlet 13 and a sludge discharge port 14, and a rotating shaft 4 and a deflector 3 are provided above the partition plate 2, and the deflector 3 The water receiving area is greater than the water spraying area of the cooling water, the middle part of the deflector 3 is bent to form a diversion groove 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com