drain pipe

A technology for drainage pipes and drainage channels, applied in the field of pipes, can solve the problems of poor safety performance of buried pipes, unable to restore sealing, pipe rupture, etc., achieve good shear resistance, good buffer performance and protection performance, reduce cooling effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

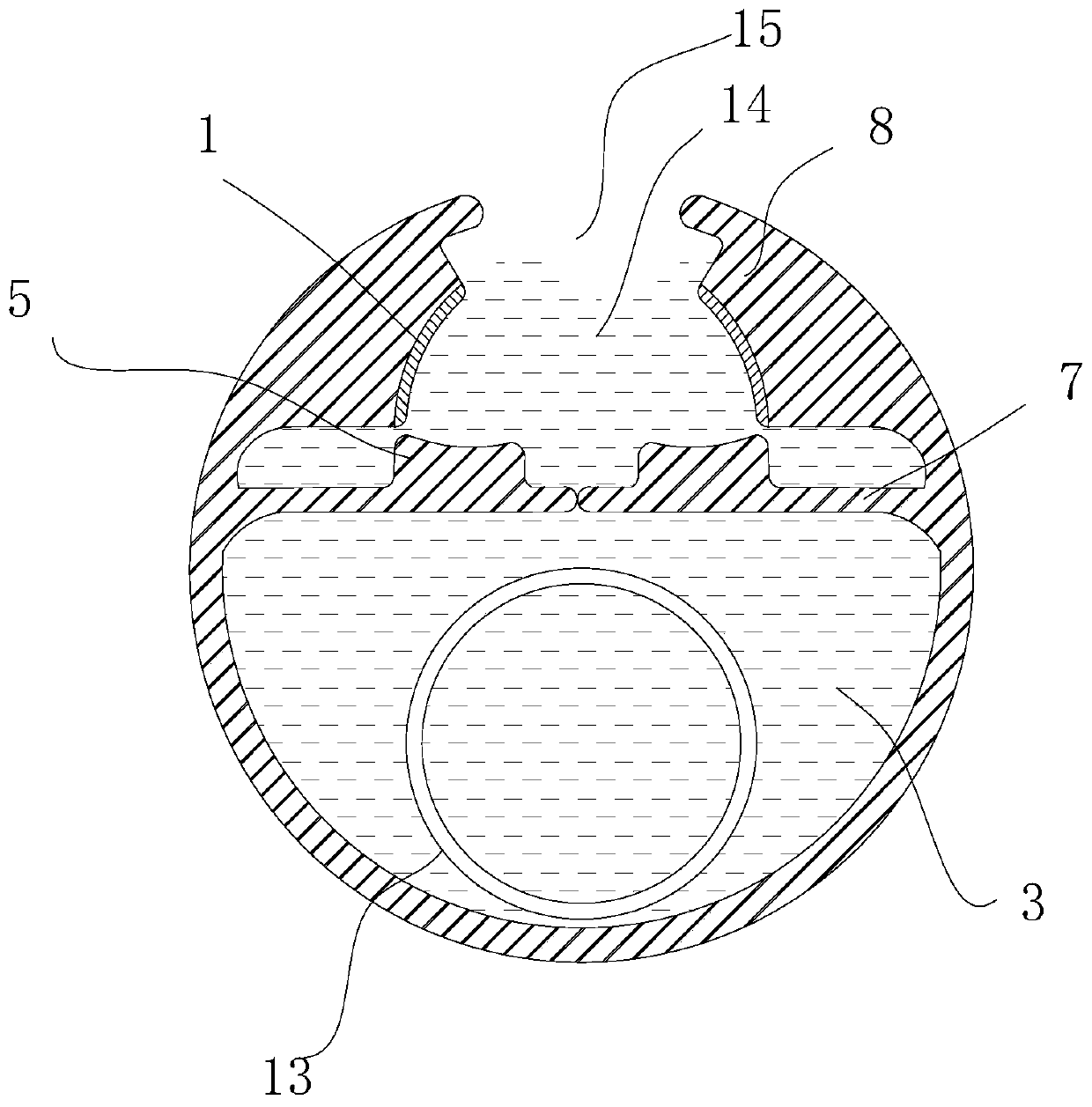

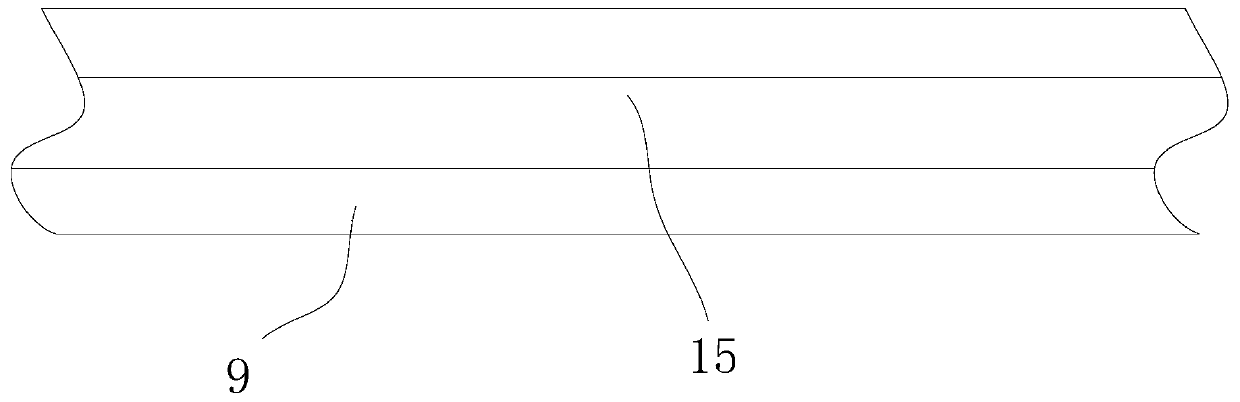

[0018] like figure 1 and image 3 Shown, this drainage pipeline comprises pipeline main body 9, and the top opening of pipeline main body 9, two dividing plates 7 are arranged in the middle of pipeline main body 9, and the opposite surfaces of two dividing plates 7 contact and seal each other, the other end of two dividing plates 7 and The pipe main body 9 is integrally connected, and the two partitions 7 cut off the drainage channel in the middle of the pipe main body. A bottom drainage chamber 3 is formed at the bottom, and a clamping chamber 14 is formed at the upper end. An intermediate pipe 13 is arranged in the clamping chamber 14. The intermediate pipe There is an independent drainage channel 11 in the middle of 13, the partition plate 7 is squeezed and deformed toward the bottom drainage chamber 3 through the middle pipe 13, and the top open end 15 of the clamping chamber 14 is sealed by the upper end surface of the middle pipe.

[0019] In this embodiment, the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com