Air inlet accurate control and sealing monitoring system of centrifugal compressor

A centrifugal compressor, precise control technology, applied in the direction of pump control, mechanical equipment, machine/engine, etc., can solve the problems of adverse impact on compressor life, low cost, fuzzy control, etc. Simple and low cost, the effect of ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

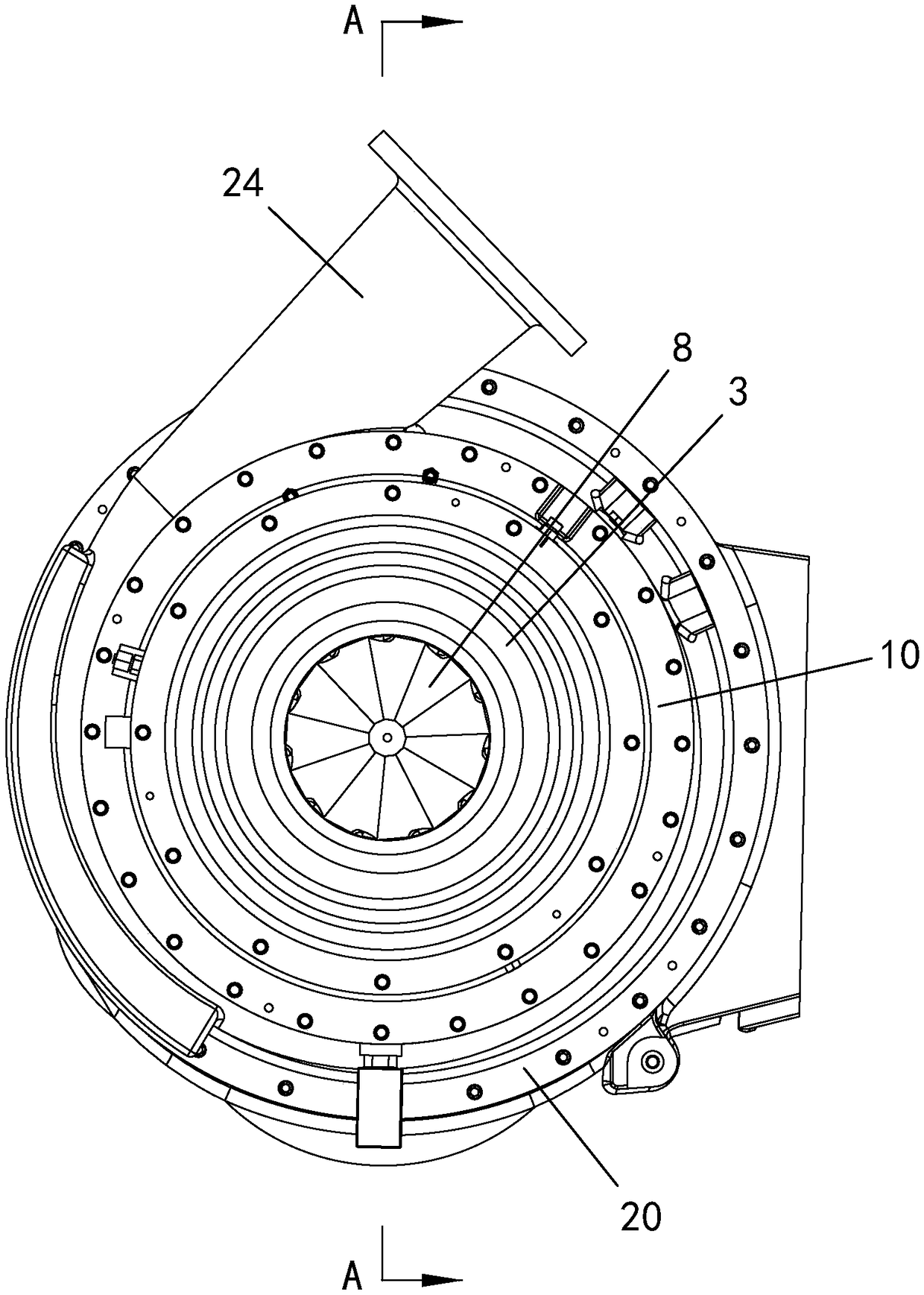

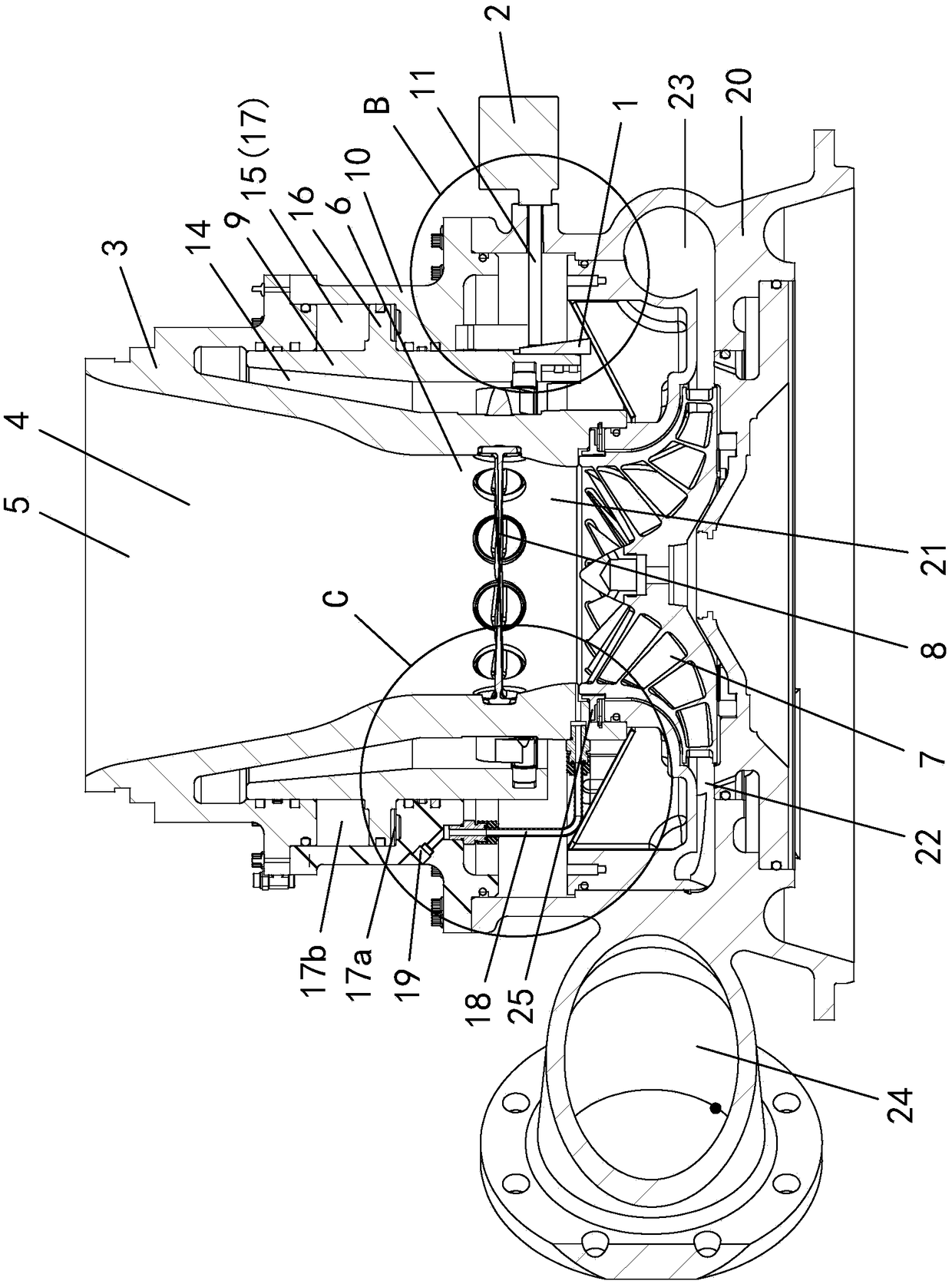

[0043] Example: see attached figure 1 , 2 As shown in the figure, a precise air intake control and tightness monitoring system for a centrifugal compressor includes an air intake precise control device and a tightness monitoring device.

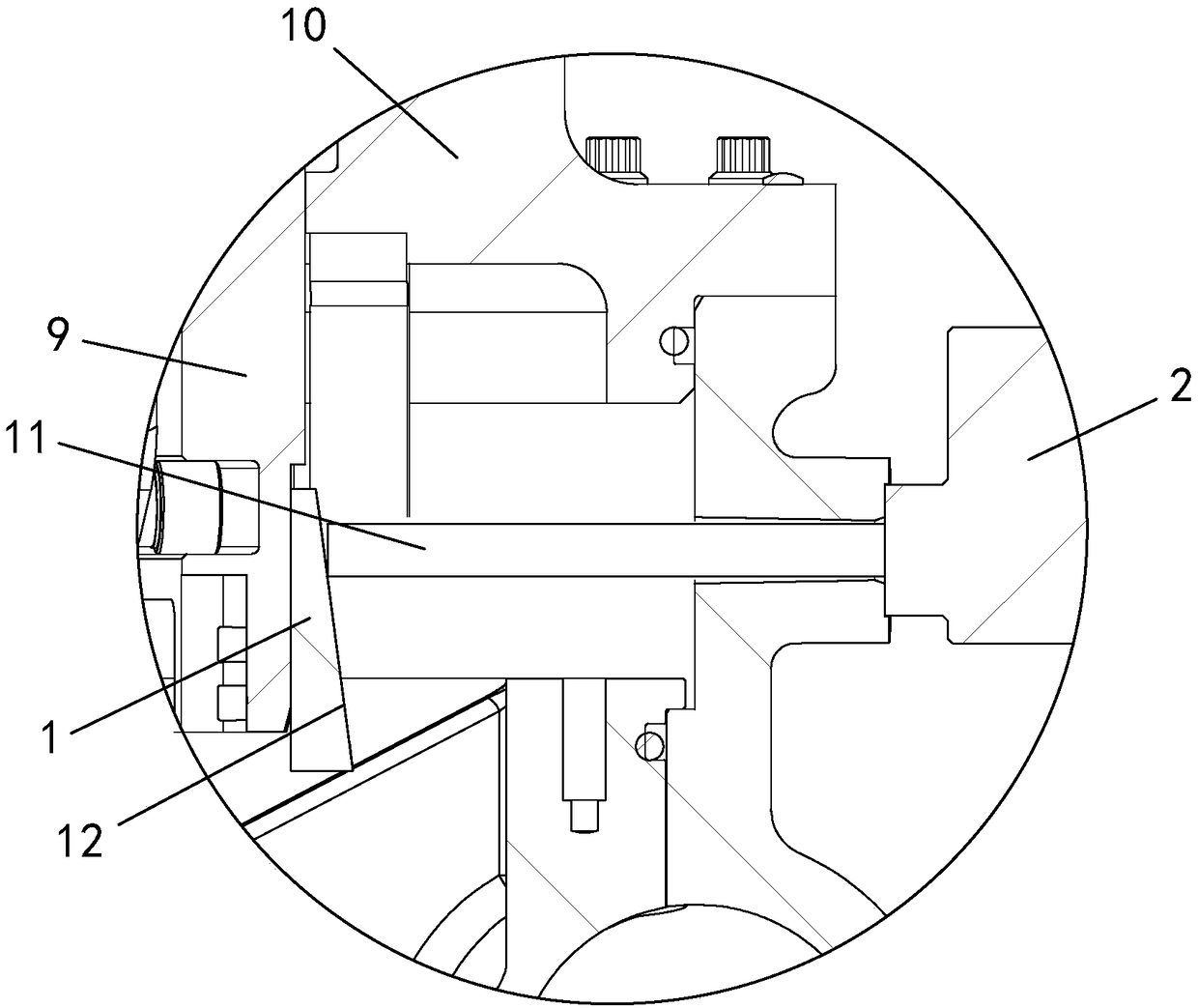

[0044] Among them, such as image 3 As shown, the air intake precise control device is set in an air intake adjustment device of the compressor, including a movement detection block 1 and a displacement sensor 2 .

[0045] The air intake adjustment device includes an air intake cylinder 3 with two ends open, the air intake cylinder 3 has an inner cavity 4, the axial section of which is rectangular or inverted trapezoidal, the inner cavity 4 communicates with the openings at both ends, forming an inlet Air flow channel; one end of the inner chamber is the air inlet end 5, and the other end is the air outlet end 6, and the air outlet end 6 is set corresponding to the impeller 7 of the compressor; in the inner chamber 4, a plurality of Blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com