Centrifugal compressor for device of converting heavy aromatics to light aromatics

A technology for lightening heavy aromatics and centrifugal compressors, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve problems such as poor economic benefits, low liquid yield, and influence on promotion. , to achieve the effect of reducing design and production costs, improving gas purity and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

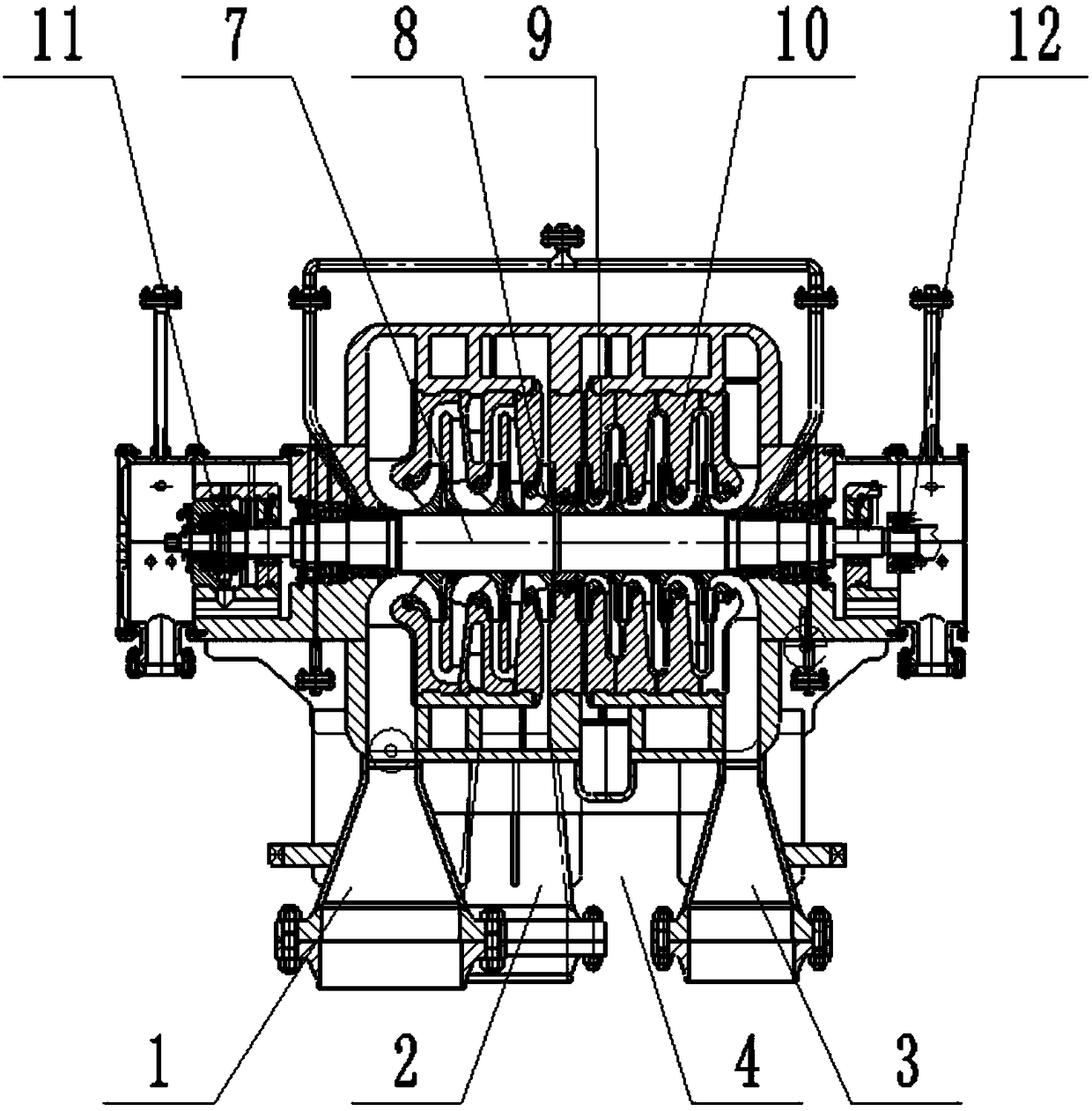

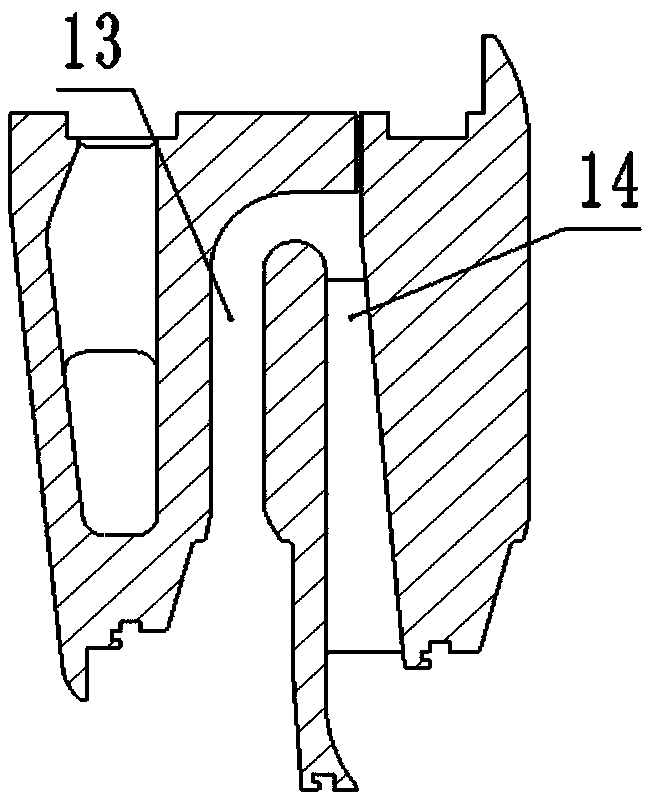

[0019] 1,000,000 tons / year heavy aromatics lightening plant gas-rich compressor unit, the diffuser adopts a vaneless diffuser with an equal-width annular flow channel formed by two parallel walls, and the diameter of the impeller is 450 mm; the vaneless diffuser The ratio of the inner diameter D3 of the impeller to the diameter D2 of the impeller is 1.09; the ratio of the inlet width b5 of the reflux device to the outlet width b4 of the diffuser is 0.75, and the inlet flow rate is 17162Nm3 / h, which meets the flow rate corresponding to the process parameters.

Embodiment 2

[0021] The energy-saving transformation of the gas-rich compressor unit of the 1 million tons / year heavy aromatics lightening plant, the diffuser adopts a vaneless diffuser with an equal-width annular flow channel composed of two parallel walls, and the diameter of the impeller is 450 mm; the vaneless The ratio of the inner diameter D3 of the diffuser to the diameter of the impeller D2 is 1.09; the ratio of the inlet width b5 of the reflux device to the width b4 of the diffuser outlet is 0.75, and the inlet flow rate is 10804Nm3 / h, which meets the flow rate corresponding to the process parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com