In-advance outburst elimination method for ground of full working face of coal mine hard roof

A hard roof and working face technology, applied in ground mining, earth drilling, underground mining, etc., can solve the problems of large pyrotechnics, high drilling costs, and inability to solve the problem of outburst elimination in the working face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] According to an embodiment of the method for eliminating the ground outburst in advance of the whole working face of the coal mine hard roof of the present invention, it comprises the following steps in sequence:

[0108] Step 1: Design drilling parameters and fracturing parameters according to the data and data collected in the previous field construction;

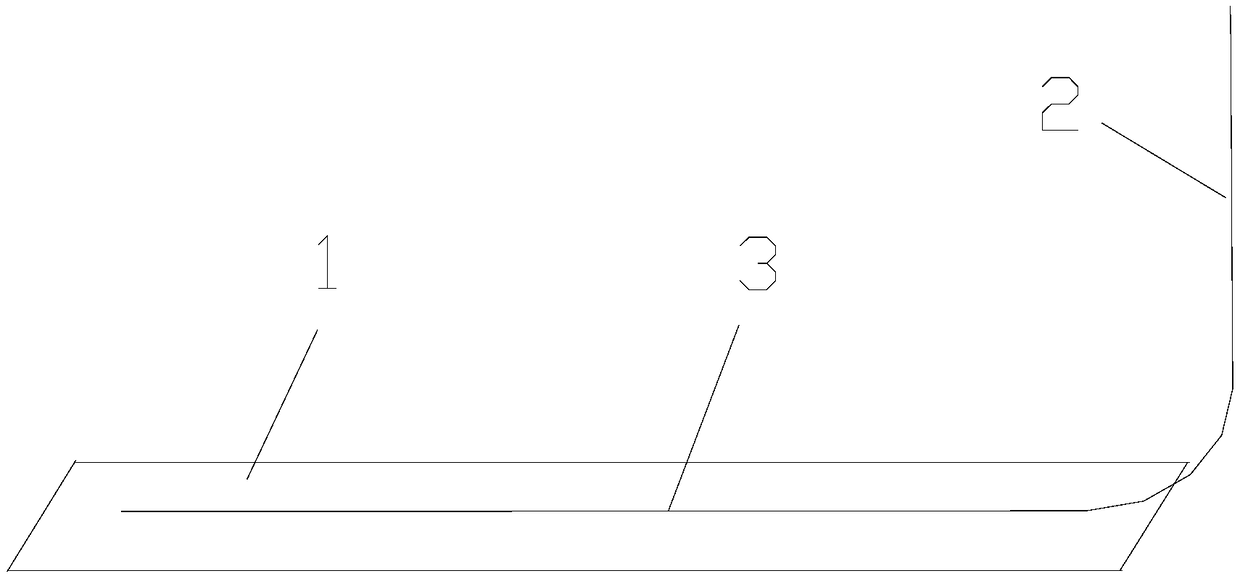

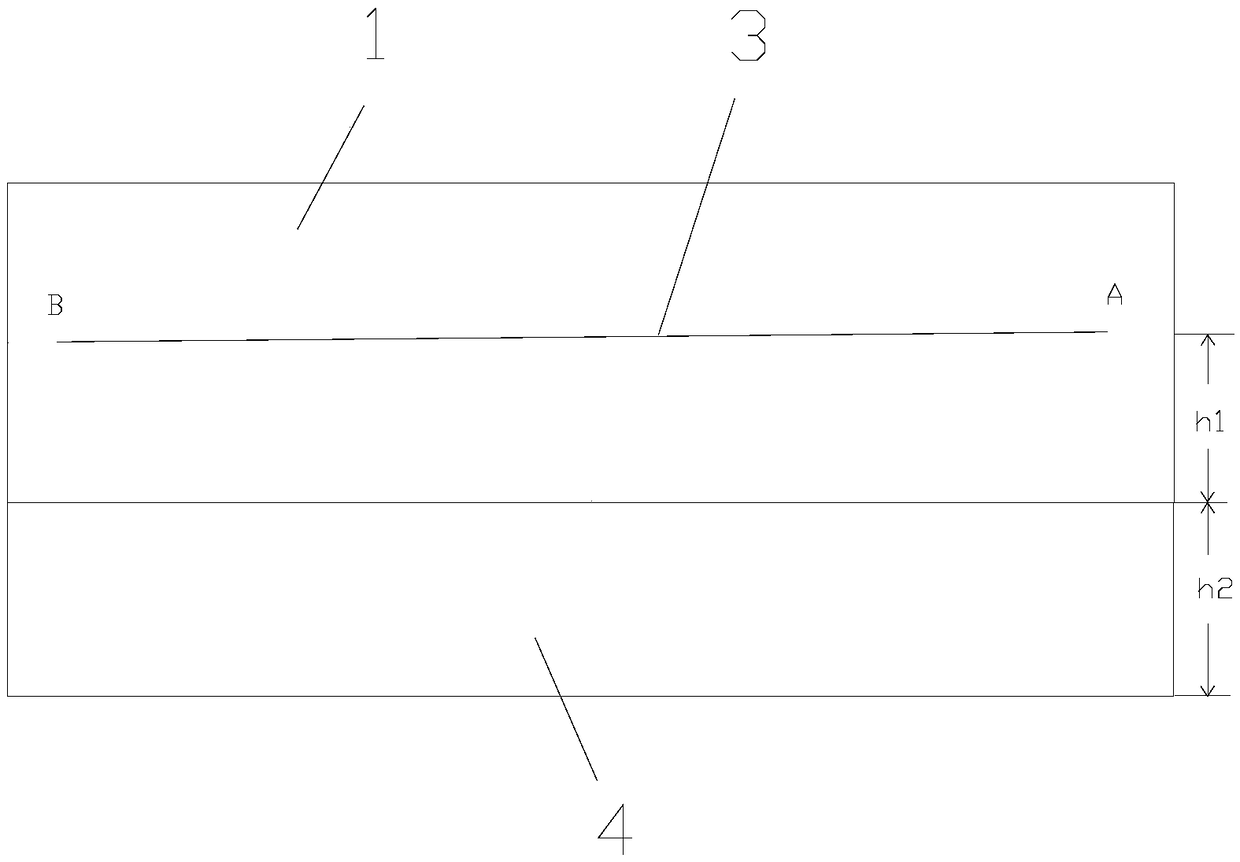

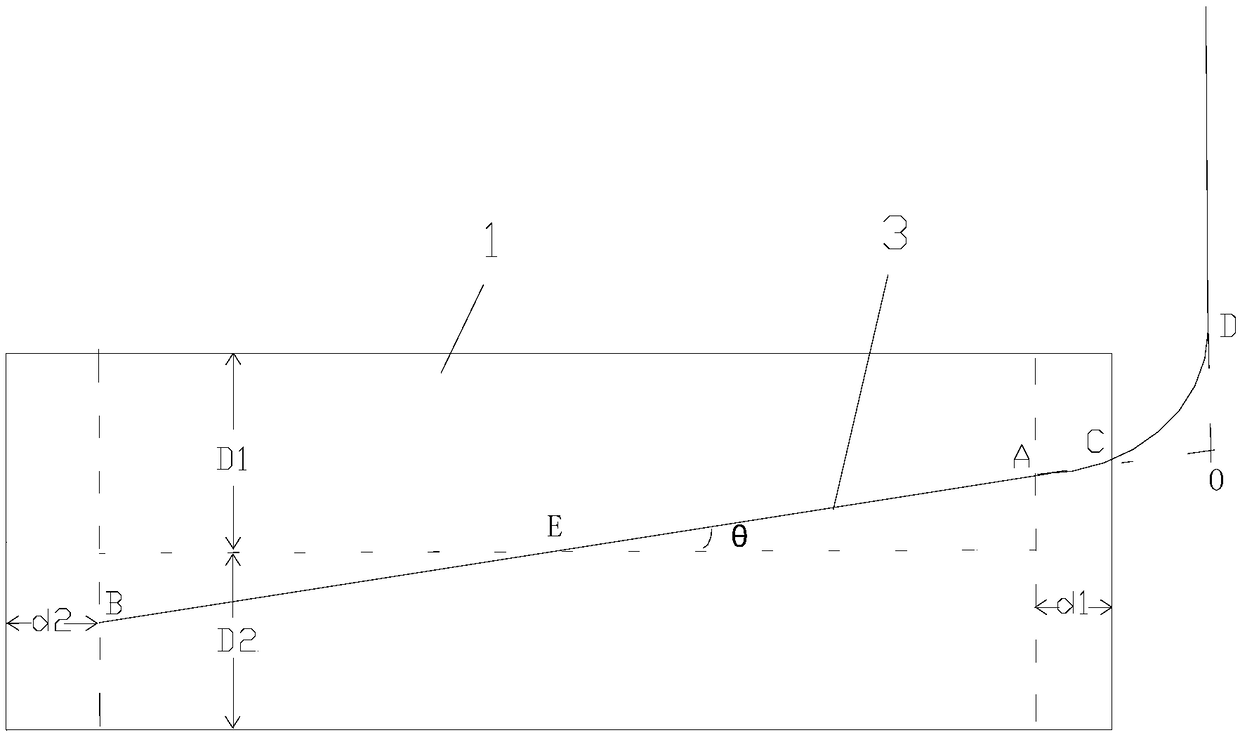

[0109] Step 2: Arrange a directional drilling rig on the ground corresponding to a certain working face of the coal mine, and use the directional drilling rig to drill a horizontal well to the preset position on the hard roof, and complete the horizontal section of the horizontal well with open holes;

[0110] Step 3: Arrange the equipment required for staged fracturing of horizontal wells at the drilling site;

[0111] Step 4: Carry out staged fracturing construction on the open-hole horizontal section of the horizontal well, so that the hard roof of the entire working face is covered with cracks, so as to achieve...

Embodiment 2

[0171] According to another embodiment of the ground outburst elimination method of the coal mine hard roof full working face in advance of the present invention, its process steps, design formulas, principles of drilling and construction parameters, construction equipment used, beneficial effects, etc. are all the same as those of the first embodiment ,the difference is:

[0172] The staged fracturing method for the horizontal section of the open hole is double-sealed and single-chassis staged fracturing. Split segment. Fracturing string: tubing + safety joint + centralizer + hydraulic packer + pressure opening sleeve + hydraulic packer + centralizer + guide shoe, fracturing the deepest part of the horizontal section first, and dragging after the first stage of fracturing Move the tubing string until the pressure-opening sliding sleeve is aligned with the second fracturing stage, fracturing the second stage, and complete the N-stage fracturing in this cycle.

[0173] The me...

Embodiment 3

[0183] According to another embodiment of the ground outburst elimination method of the coal mine hard roof full working face in advance of the present invention, its process steps, design formulas, principles of drilling and construction parameters, construction equipment used, beneficial effects, etc. are all the same as those of the first embodiment ,the difference is:

[0184] The staged fracturing method of the horizontal section of the open hole is a ball-sliding sleeve staged fracturing method. The main features of this fracturing method are "ball-sliding sleeves" and "immobile strings", that is, completion strings and fracturing strings are used. The split pipe strings are combined into one string and run together, and tools such as hanging packers, expandable open-hole packers, ball-pitching sleeves, differential pressure sleeves, and setting ball seats are used to run into the well. Fracturing string: hanging packer + open hole packer N + ball sliding sleeve N + divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com