Auxiliary painting equipment for putty on back face of building decoration ceramic tile

A putty and ceramic tile technology, which is applied in the field of putty auxiliary application equipment on the back of tiles, can solve the problems of time-consuming and energy-consuming, and achieve the effect of avoiding precipitation and improving the paste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

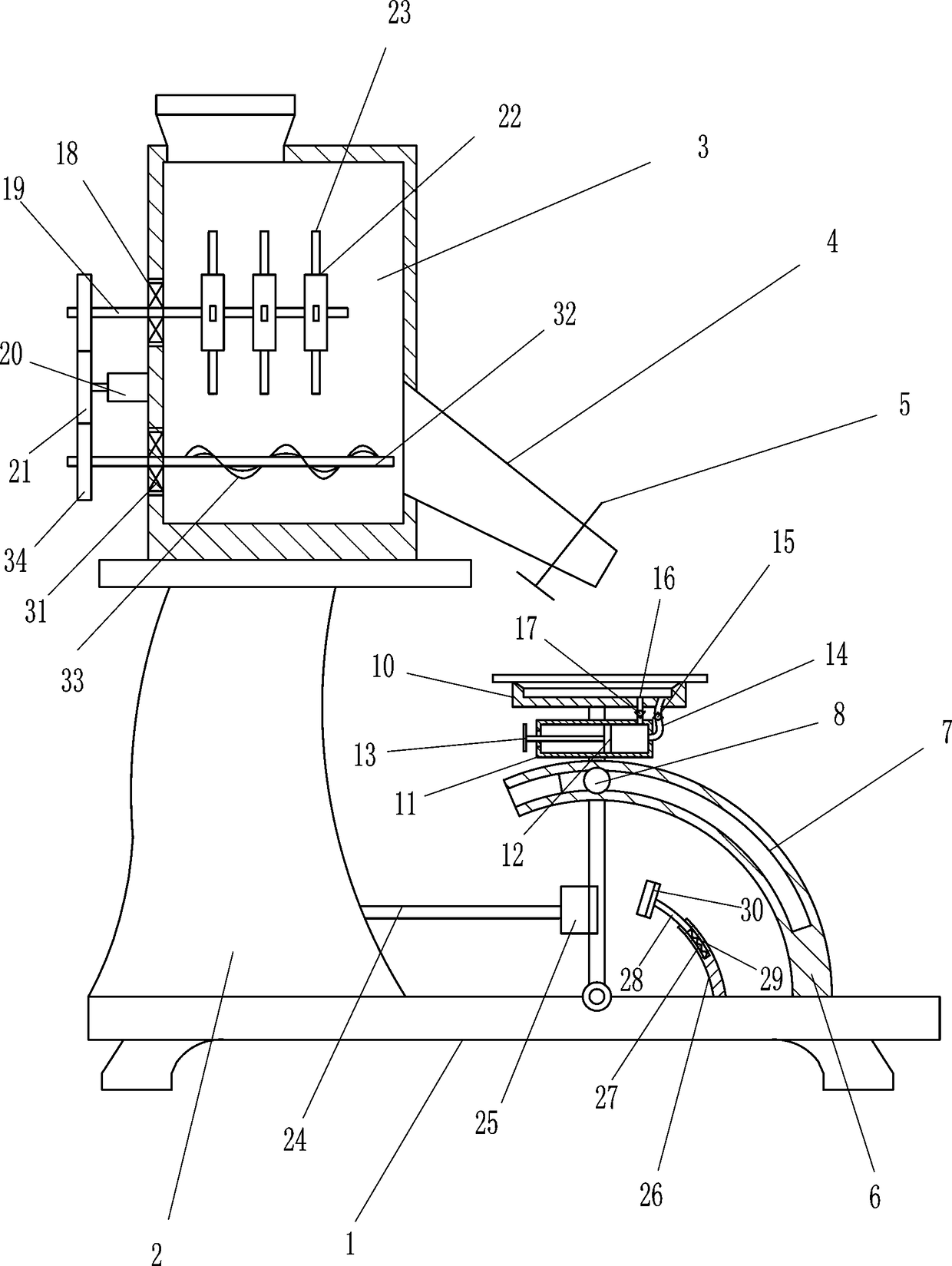

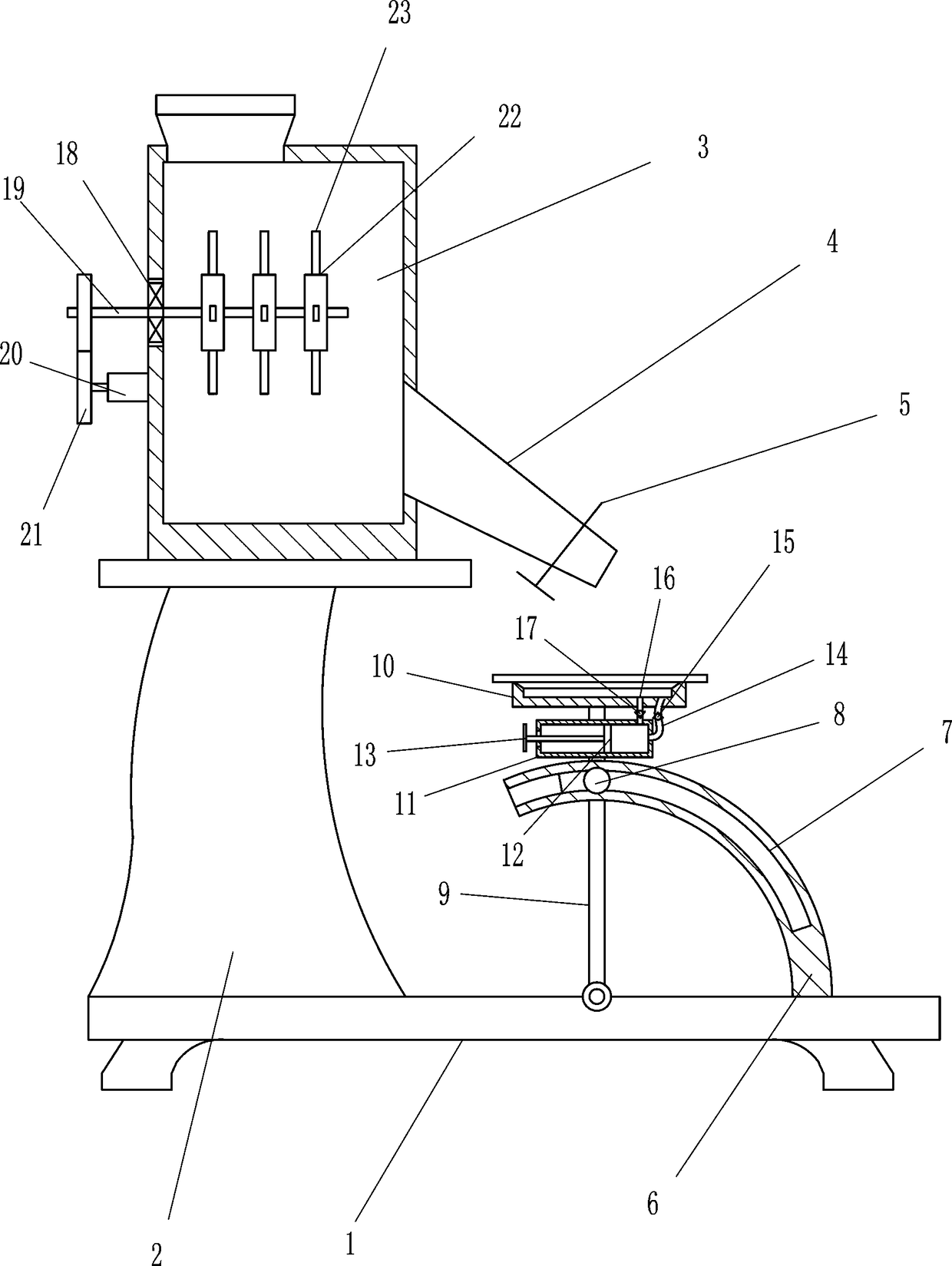

[0025] A kind of equipment for auxiliary application of putty on the back of building decoration tiles, such as Figure 1-5As shown, it includes a base 1, a support 2, a putty bucket 3, a funnel 4, a valve 5, an arc plate 6, a slideway 7, a sliding shaft 8, a swing rod 9, a suction cup 10, a cylinder body 11, a piston 12, and a pull rod 13. The first pipeline 14, the first one-way valve 15, the second pipeline 16 and the second one-way valve 17, the top left side of the base 1 is provided with a support 2, and the top of the support 2 is provided with a putty bucket 3, putty The lower right side of the bucket 3 is connected with a funnel 4, the funnel 4 communicates with the putty bucket 3, the funnel 4 is provided with a valve 5, the top right side of the base 1 is provided with an arc-shaped plate 6, and the arc-shaped plate 6 is provided with a slideway 7 , the arc-shaped plate 6 is slidably connected with a sliding shaft 8, the middle of the top of the base 1 is hingedly c...

Embodiment 2

[0027] A kind of equipment for auxiliary application of putty on the back of building decoration tiles, such as Figure 1-5 As shown, it includes a base 1, a support 2, a putty bucket 3, a funnel 4, a valve 5, an arc plate 6, a slideway 7, a sliding shaft 8, a swing rod 9, a suction cup 10, a cylinder body 11, a piston 12, and a pull rod 13. The first pipeline 14, the first one-way valve 15, the second pipeline 16 and the second one-way valve 17, the top left side of the base 1 is provided with a support 2, and the top of the support 2 is provided with a putty bucket 3, putty The lower right side of the bucket 3 is connected with a funnel 4, the funnel 4 communicates with the putty bucket 3, the funnel 4 is provided with a valve 5, the top right side of the base 1 is provided with an arc-shaped plate 6, and the arc-shaped plate 6 is provided with a slideway 7 , the arc-shaped plate 6 is slidably connected with a sliding shaft 8, the middle of the top of the base 1 is hingedly ...

Embodiment 3

[0030] A kind of equipment for auxiliary application of putty on the back of building decoration tiles, such as Figure 1-5 As shown, it includes a base 1, a support 2, a putty bucket 3, a funnel 4, a valve 5, an arc plate 6, a slideway 7, a sliding shaft 8, a swing rod 9, a suction cup 10, a cylinder body 11, a piston 12, and a pull rod 13. The first pipeline 14, the first one-way valve 15, the second pipeline 16 and the second one-way valve 17, the top left side of the base 1 is provided with a support 2, and the top of the support 2 is provided with a putty bucket 3, putty The lower right side of the bucket 3 is connected with a funnel 4, the funnel 4 communicates with the putty bucket 3, the funnel 4 is provided with a valve 5, the top right side of the base 1 is provided with an arc-shaped plate 6, and the arc-shaped plate 6 is provided with a slideway 7 , the arc-shaped plate 6 is slidably connected with a sliding shaft 8, the middle of the top of the base 1 is hingedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com