Real stone paint coating with good firmness

A real stone paint and firmness technology, applied in the field of coatings, can solve problems such as weak attachment, achieve the effects of simple structure, avoid falling off, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

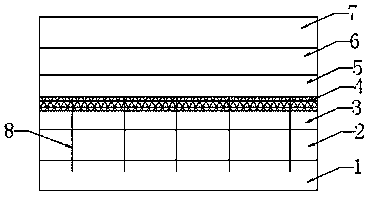

[0018] The invention discloses a real stone paint coating with good firmness, which comprises a putty layer 2, a primer layer 3, an alkali-resistant glass fiber grid reinforcement layer 4, a real stone paint layer 5, and a waterproof paint layer coated on the outer side of an exterior wall base layer 1 in sequence. film layer 6 and overcoat layer 7.

[0019] Wherein, the reinforcement steel wire 8 that runs through the putty layer 2 is connected between the exterior wall base 1 and the alkali-resistant glass fiber grid reinforcement layer 4, the diameter of the reinforcement steel wire 8 is 1-3mm, one end of which is inserted into It is fixed in the base layer 1 of the exterior wall, and the other end is hooked on the reinforcement layer 4 of the alkali-resistant glass fiber mesh. There are multiple reinforcing steel wires 8, which are evenly distributed at equal intervals. Through the design of alkali-resistant glass fiber grid reinforcing layer 4 and reinforcing steel wire ...

Embodiment 2

[0024] The difference from Example 1 is that the number of layers of the alkali-resistant glass fiber grid reinforcement layer 4 is 2 or 3 layers, and the reinforcement steel wire 8 runs through the alkali-resistant glass fiber grid reinforcement layer of the inner layer, and the outermost The alkali-resistant glass fiber mesh reinforcement layer is hooked and connected, and the 2 or 3 layers of alkali-resistant glass fiber mesh reinforcement layer 4 are tightly connected, and the primer layer 3 starts from the inside of the alkali-resistant glass fiber mesh reinforcement layer 4. One side is infiltrated, and the real stone paint layer 5 is infiltrated from the other side of the outermost alkali-resistant glass fiber mesh reinforcement layer 4, and the primer layer 3 and the real stone layer are connected by 2 or 3 layers of alkali-resistant glass fiber mesh reinforcement layers. The paint layer 5 can be firmly adhered to the alkali-resistant glass fiber mesh reinforcement laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com