Speed bump mounting device

A technology for installation devices and speed bumps, which is applied in roads, road signs, traffic signals, etc., can solve the problems of unfavorable health of workers, delay of installation progress, and low installation efficiency, so as to protect health, improve installation efficiency, and ensure installation progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

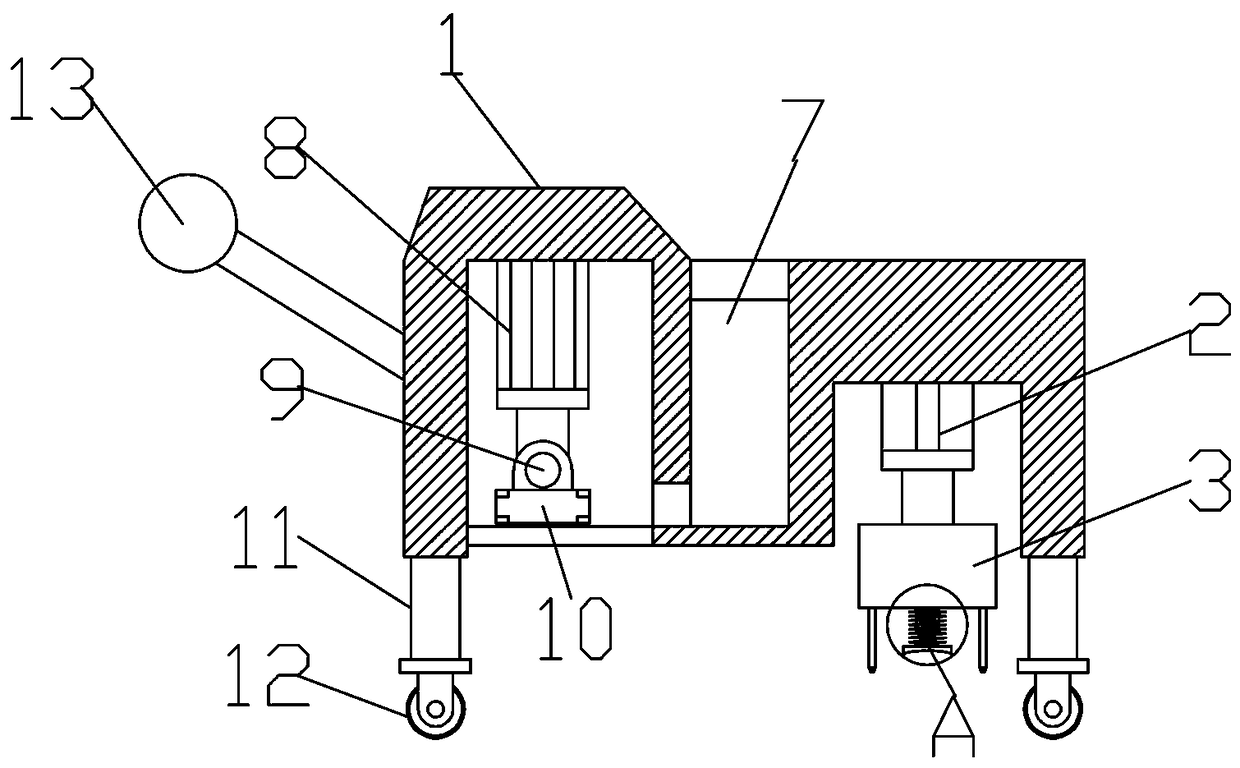

[0013] Attached below Figure 1-4 The specific implementation of the present invention will be described in further detail.

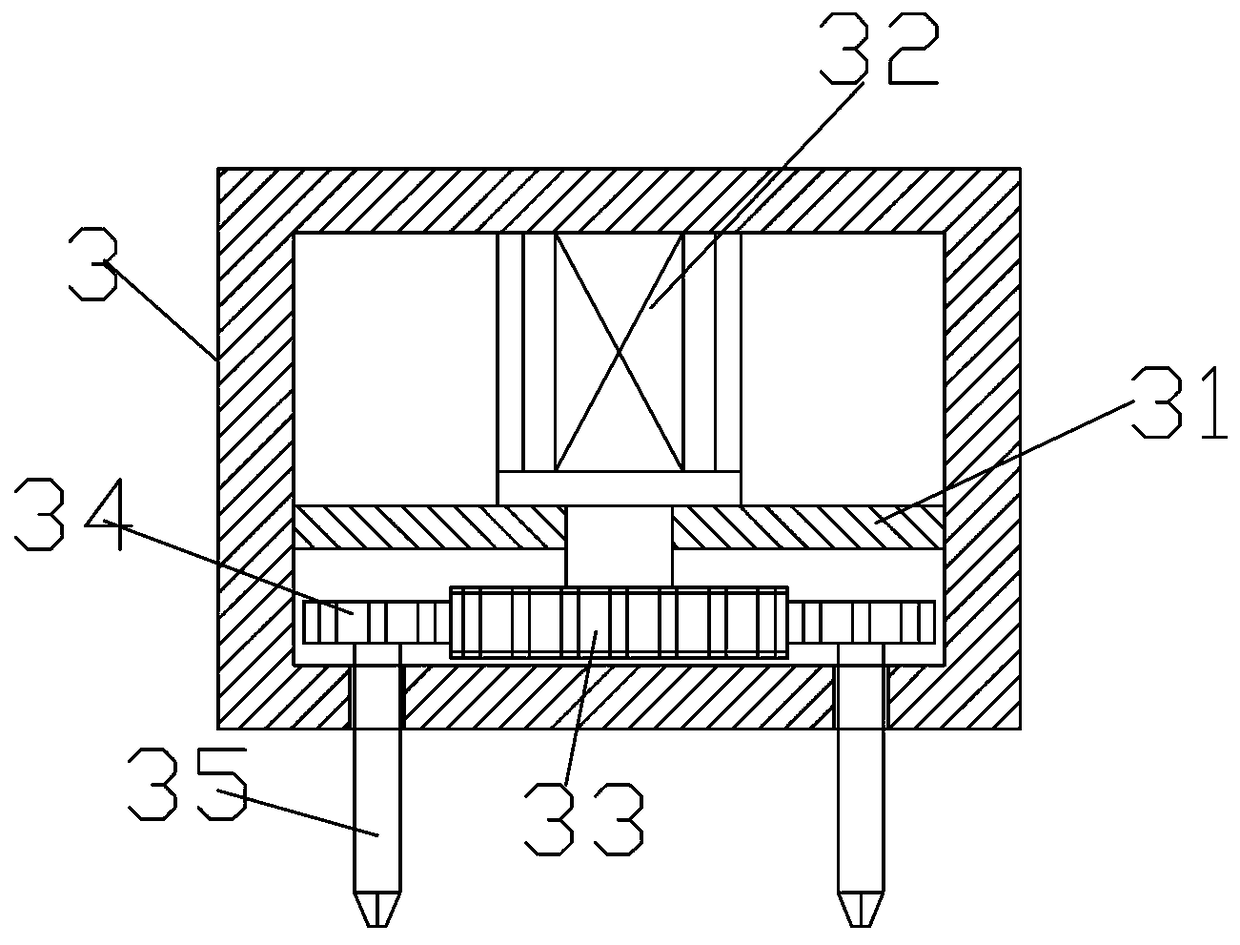

[0014] by Figure 1-4 Given that the present invention includes a mounting frame 1, a MPT63 pressurized cylinder 2 is fixed at the middle of one side of the mounting frame 1, a punch assembly 3 is fixed at the bottom end of the MPT63 pressurized cylinder 2, and a partition 31 is fixed at the bottom of the punch assembly 3, A GSR7.2-1 motor 32 is installed inside the punching assembly 3 through the middle of the partition 31. The bottom end of the GSR7.2-1 motor 32 is fixed with a first gear 33, and both ends of the first gear 33 are connected with a second gear 34. The bottom end of the second gear 34 penetrates through the bottom end of the punching assembly 3 and an electric rotor 35 is fixed at the bottom end. The bottom end of the punching assembly 3 is fixed with a telescopic rod 4, the bottom end of the telescoping rod 4 is installed with an arc pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com