Powder feeding device capable of realizing powder gradient change and for laser cladding

A technology of powder feeding device and gradient change, which is applied in the field of powder feeding device, can solve the problems of lower production efficiency, low powder utilization efficiency, blockage of laser cladding head of powder feeding pipeline, etc., to improve the degree of uniformity, improve utilization efficiency, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

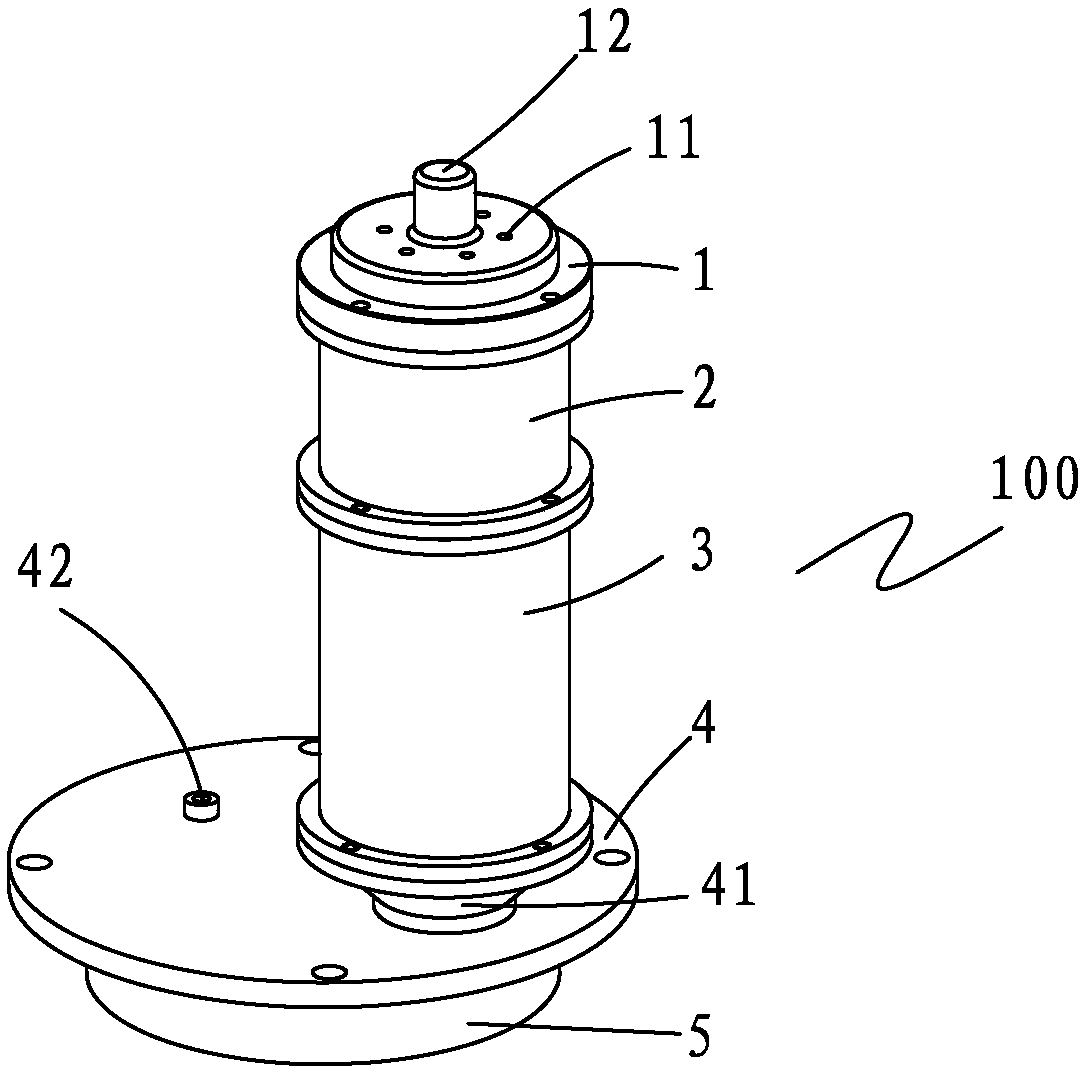

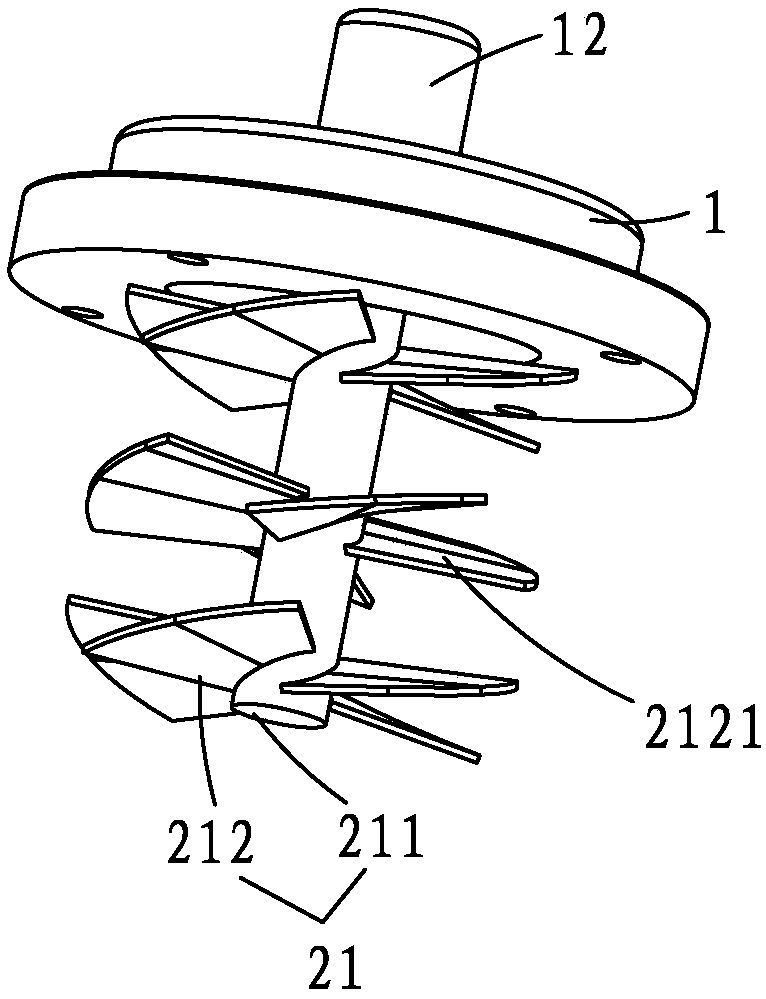

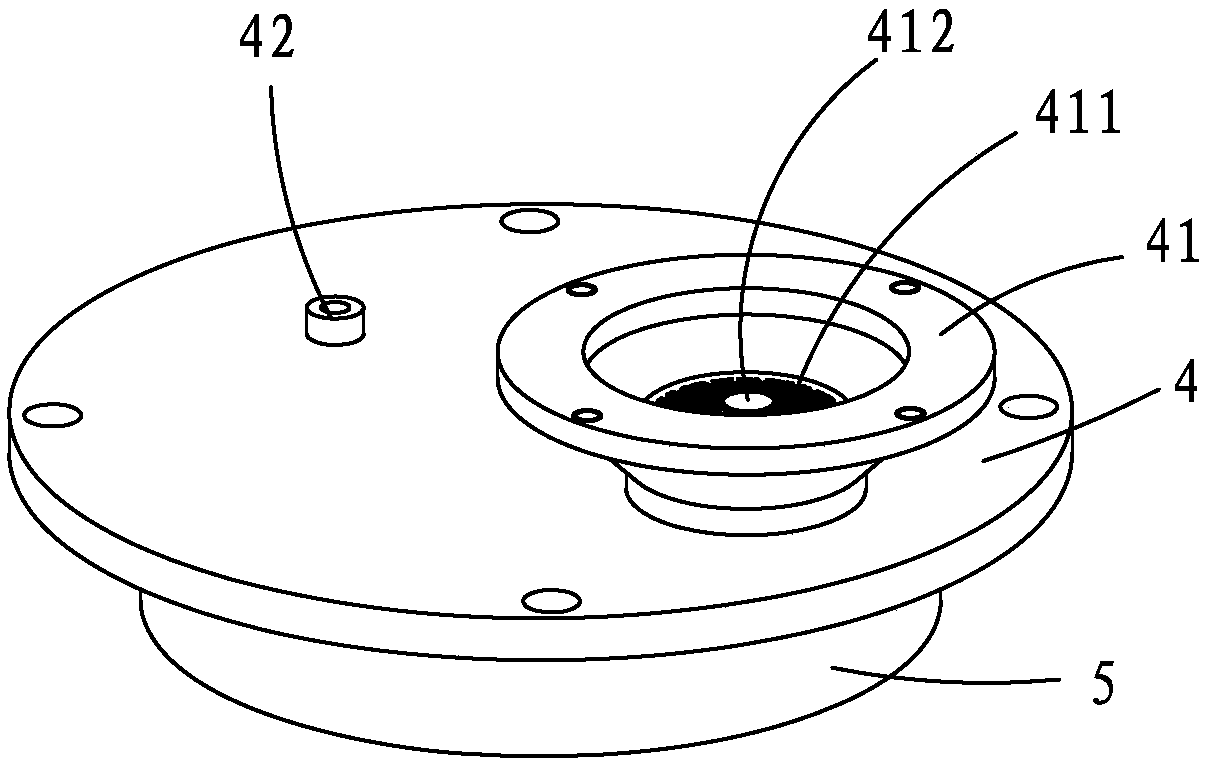

[0024] see Figure 1~4 , the present invention relates to a powder feeding device for laser cladding that can realize powder gradient changes. The powder feeding device 100 includes a top end cover 1, a powder mixing bin 2, a powder storage bin 3, a powder storage bin base 4 and a fixing seat 5, The top end cover 1 is arranged on the top of the powder mixing chamber 2, and a plurality of powder feeding holes 11 are provided on the top end cover 1, and a rotating powder mixing device 21 is arranged in the powder mixing chamber 2, and the rotating powder mixing device 21 is arranged in the powder mixing chamber 2. The device 21 is connected to the motor 12 through the top end cover 11, the motor 12 is arranged outside the top end cover 1, the powder storage bin 3 is connected to the other end of the powder mixing bin 2, and the powder storage bin base 4 is arranged below the powder storage bin 3 ;

[0025] The base of the powder storage bin 4 is connected and arranged above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com