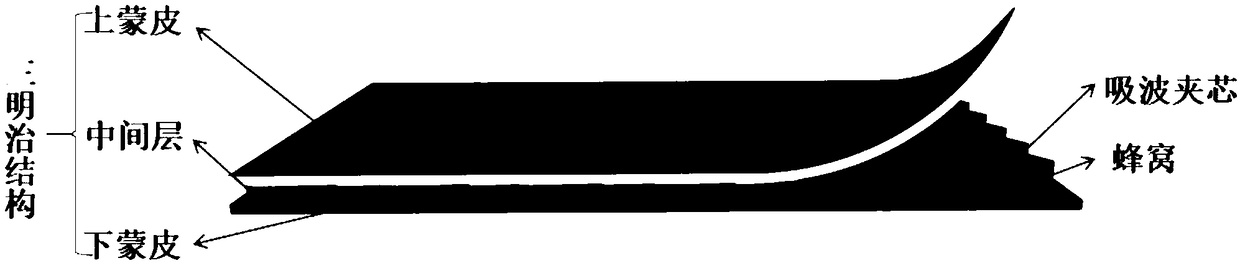

Sandwich structure wave-absorbing composite material and preparation method thereof

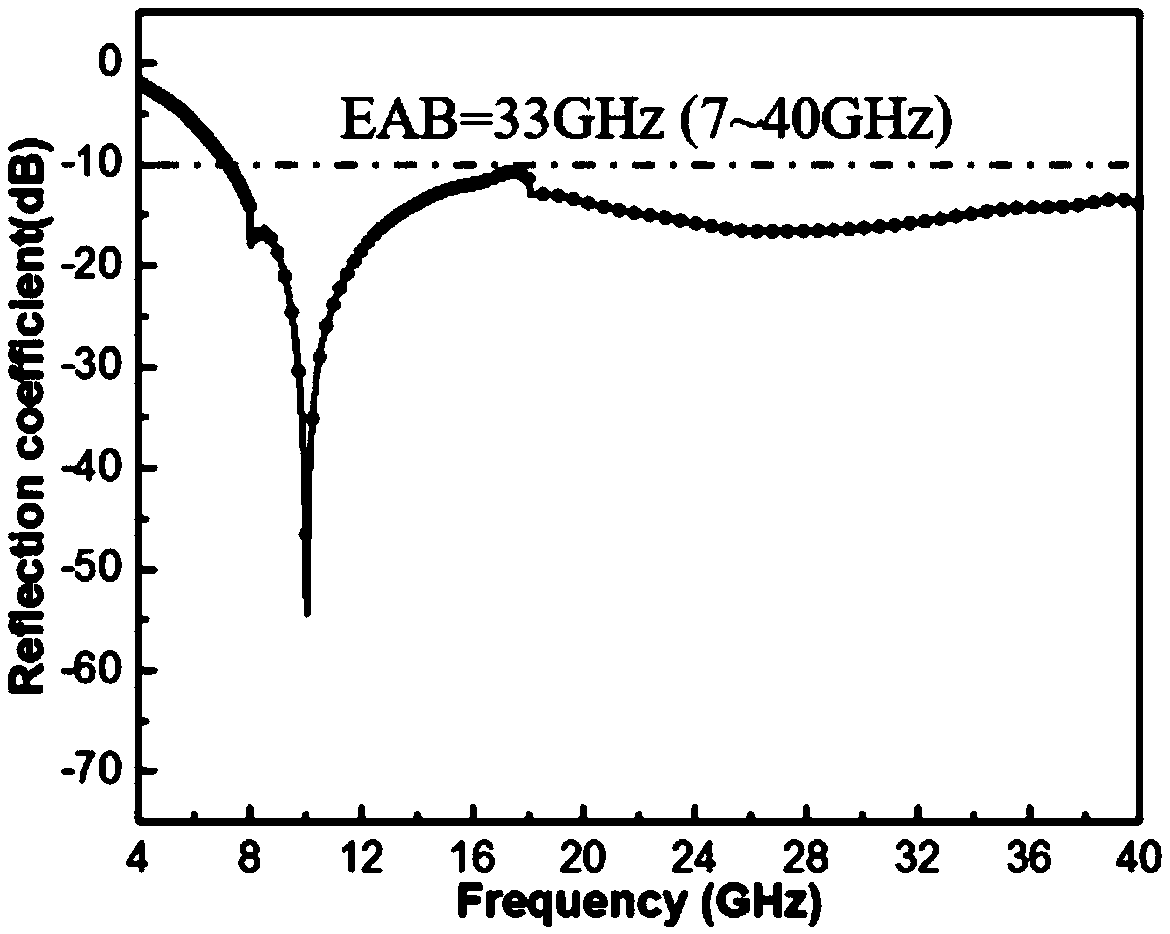

A composite material and sandwich technology, which is applied in the field of electromagnetic wave stealth, can solve the problems of difficult coordination between effective load bearing and broadband strong absorbing performance, large density and thickness, and complicated preparation process, so as to achieve high process control and reliability, and reduce reflection , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Place 3 g of carbon nanotubes in 97 ml of deionized water, stir and ultrasonically disperse for 3 hours to obtain a uniformly dispersed aqueous dispersion of carbon nanotubes; place 4.5 g of cellulose in 295.5 ml of deionized water, stir and ultrasonically disperse for 3 hours, Obtain a cellulose aqueous solution; mix and stir the obtained carbon nanotube aqueous dispersion and cellulose aqueous solution, and ultrasonically obtain a mixed solution for 3 hours; place the mixed solution in a cell with a cell size of 2 mm, a thickness of 5 mm, and a density of 30 kg / m 3 In the cells of the honeycomb material, the temperature was lowered at 5°C / min to -60°C for 6 hours, and dried under 0.1Pa vacuum condition for 30 hours. That is, an intermediate layer with absorbing properties is obtained.

[0030] (2) Put the cut single-layer glass fiber / carbon fiber cloth into the epoxy resin glue solution, completely soak the fiber cloth for 2 hours, take it out, and remove the exce...

Embodiment 2

[0033] (1) Place 2.6g of carbon nanotubes in 97.4ml of deionized water, stir and ultrasonically disperse for 3 hours to obtain a uniformly dispersed aqueous dispersion of carbon nanotubes; place 4.5g of cellulose in 295.5ml of deionized water, stir and ultrasonically disperse 3h to obtain a cellulose aqueous solution; mix and stir the obtained carbon nanotube aqueous dispersion and cellulose aqueous solution, and ultrasonically obtain a mixed solution for 3 hours; place the mixed solution in a cell with a cell size of 5mm, a thickness of 10mm, and a density of 48kg / m 3 In the cells of the honeycomb material, the temperature was lowered to -60°C at 5°C / min for pre-freezing for 6 hours, and dried under 0.1Pa vacuum for 36 hours. That is, an intermediate layer with absorbing properties is obtained.

[0034](2) Put the three layers of cut glass fiber / carbon fiber cloth into the phenolic resin glue, soak the fiber cloth for 2 hours, take it out, and remove the excess resin on the s...

Embodiment 3

[0037] (1) Put 2g of carbon nanotubes in 98ml of deionized water, stir and ultrasonically disperse for 3 hours to obtain a uniformly dispersed aqueous dispersion of carbon nanotubes; place 3g of cellulose in 297ml of deionized water, stir and ultrasonically disperse for 3 hours to obtain fibers plain aqueous solution; the obtained carbon nanotube aqueous dispersion and cellulose aqueous solution were mixed and stirred, and the mixed solution was obtained by ultrasonication for 3 hours; the mixed solution was placed in a cell size of 4mm, a thickness of 10mm, and a density of 48kg / m 3 In the cells of the honeycomb material, the temperature was lowered at 5°C / min to -60°C for 8 hours, and dried under 0.1Pa vacuum condition for 34 hours. That is, an intermediate layer with absorbing properties is obtained.

[0038] (2) Put 10 layers of cut glass fiber / carbon fiber cloth into the polyimide resin glue solution, completely soak the fiber cloth for 3 hours, take it out, and remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com