Composite rubber mat for pot bearing, and production method thereof

A technology for compounding rubber and rubber pads, which is applied in rubber layered products, chemical instruments and methods, and layered products, etc., can solve the problems of shear damage of rubber pads, prone to internal defects, and wear of rubber surface layers, so as to solve the problems of wear and tear. , Improve the compactness and vulcanization quality of the adhesive layer, and the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

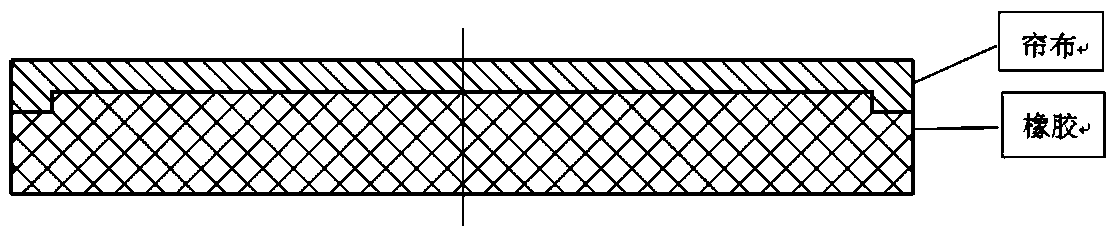

[0029] A kind of composite rubber pad for basin bearing of the present invention, its structure is as figure 1 As shown, it includes the rubber pad body and the ply layer located on the upper layer of the rubber pad body, and the ply layer is composed of ply and rubber.

[0030] The preparation method of the composite rubber pad for the pot bearing of the present embodiment comprises the following steps:

[0031] (1) Preparation of rubber compound: Weigh the weight of each raw material: 90 parts of NR90, 10 parts of SBR, 3 parts of zinc oxide, 5 parts of stearic acid, 65 parts of carbon black, 10 parts of plasticizer DOP, 1.5 parts of accelerator CZ , 2 parts of sulfur, 2 parts of anti-aging agent 4010NA, mixed by the one-stage process of internal mixer, and mixed with raw rubber and other additives except vulcanization system (sulfur and accelerator CZ) at a speed of 40r / min 5min, then adjust the rotation speed to 30r / min, add sulfur and accelerator CZ, control the temperatu...

Embodiment 2

[0037] A composite rubber pad for pot bearings according to the present invention comprises a rubber pad body and cord layers located on the upper and lower surfaces of the rubber pad body, and the cord layer is compounded by cord cloth and rubber.

[0038] The preparation method of the composite rubber pad for the pot bearing of the present embodiment comprises the following steps:

[0039] (1) Preparation of rubber compound: Weigh the weight of each raw material: 90 parts of NR90, 10 parts of SBR, 3 parts of zinc oxide, 5 parts of stearic acid, 65 parts of carbon black, 10 parts of plasticizer DOP, 1.5 parts of accelerator CZ , 2 parts of sulfur, 2 parts of anti-aging agent 4010NA, mixed by the one-stage process of internal mixer, and mixed with raw rubber and other additives except vulcanization system (sulfur and accelerator CZ) at a speed of 40r / min 5min, then adjust the rotation speed to 30r / min, add sulfur and accelerator CZ, control the temperature below 135°C, and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com