Portable platform mechanism used for industrial digital printing of shoes

A digital printing and portable technology, applied in processing platforms/substrates, additive processing, etc., can solve problems such as unsatisfactory printing efficiency and quality, and achieve the effects of increasing service life, improving printing quality, and buffering extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

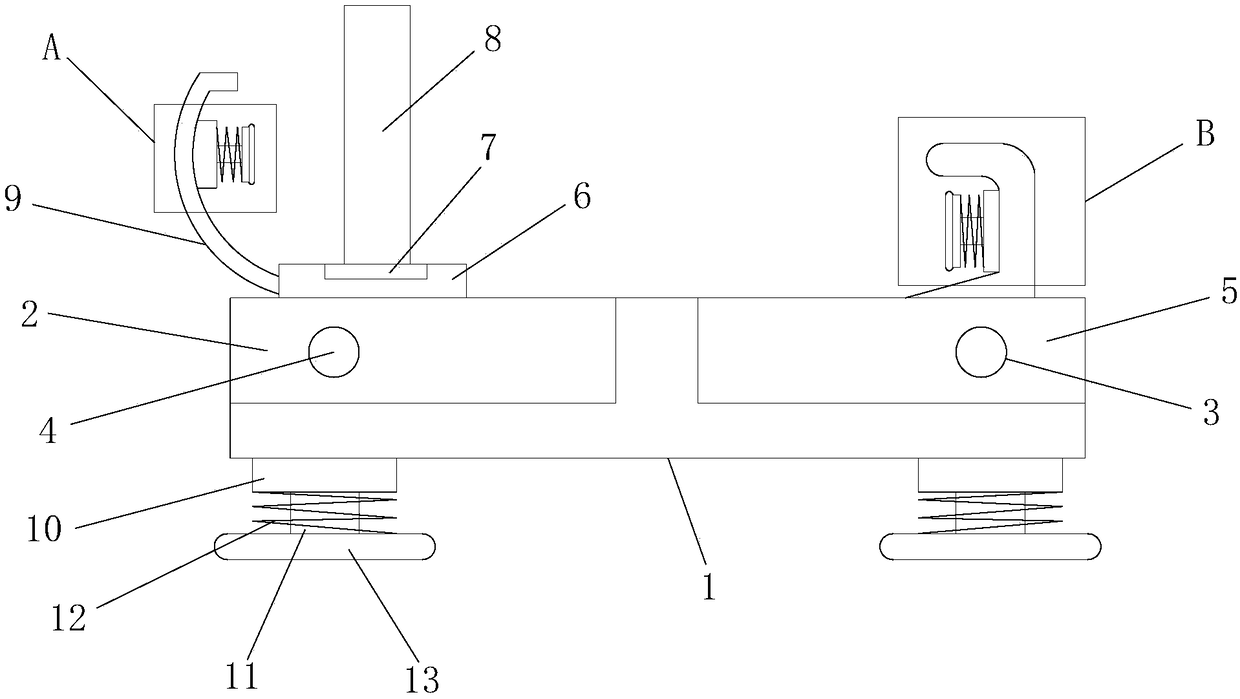

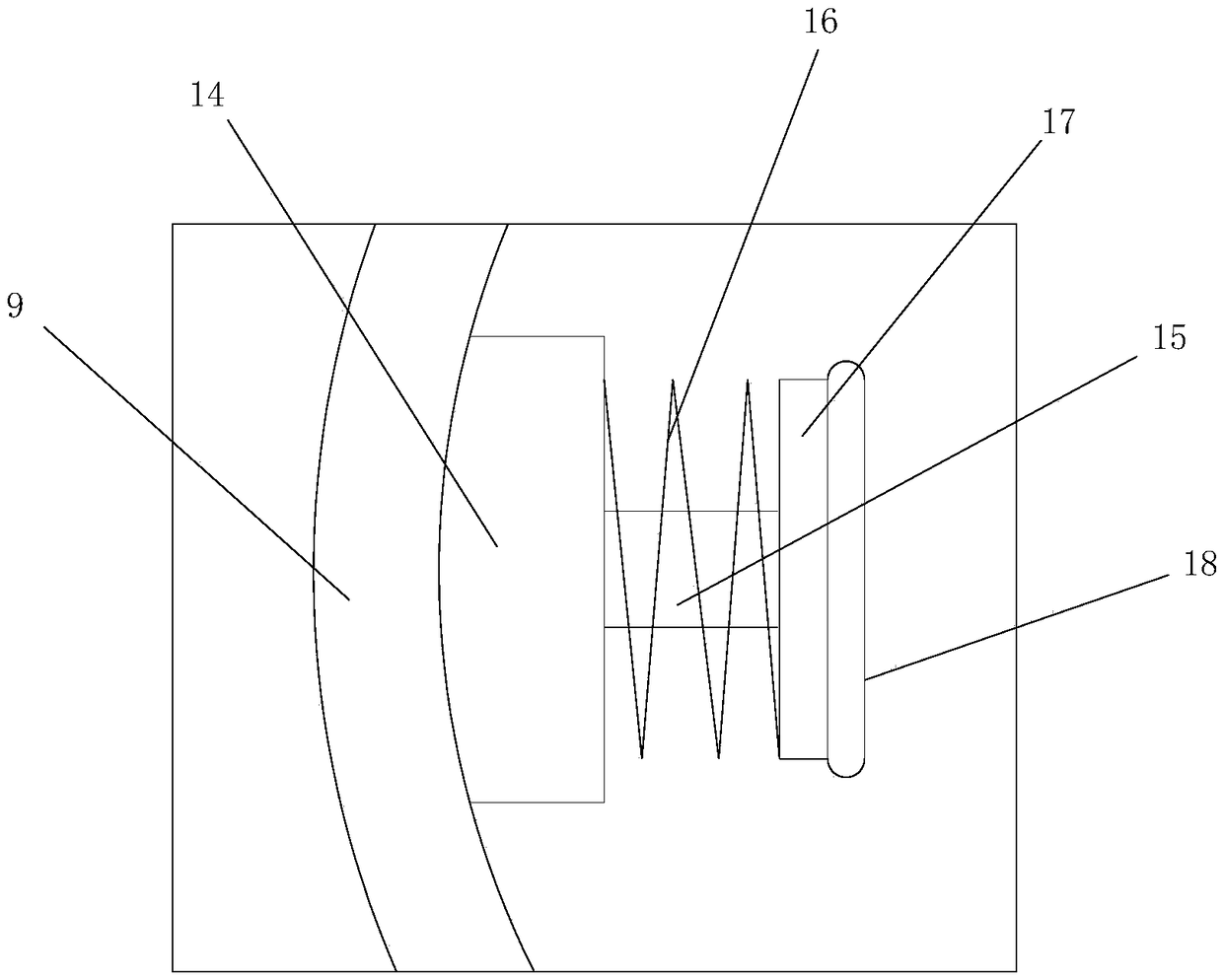

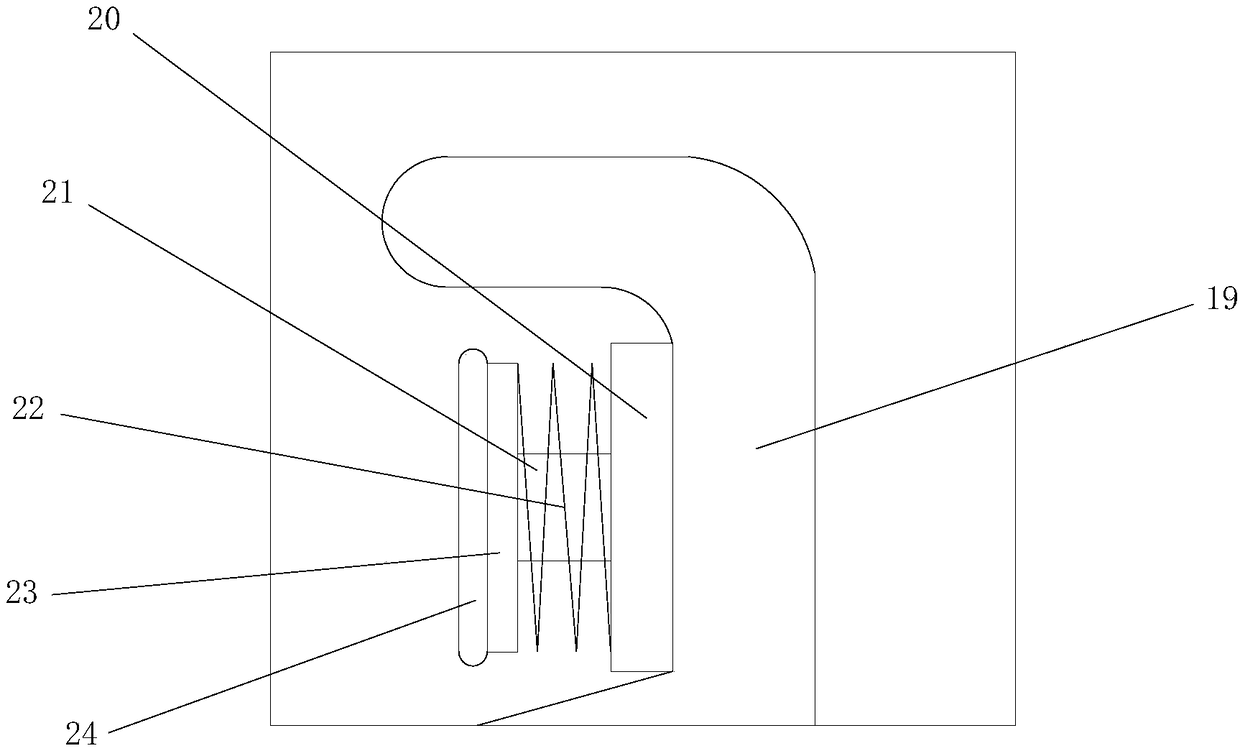

[0034] Such as Figure 1-5As shown, the present invention provides a platform mechanism for portable industrial digital printing of shoes, including a base 1, on which a first chute 2 and a second chute 3 are arranged, and inside the first chute 2 A first pulley 4 is provided, a second chute 5 is arranged in the second chute 3, a first slide plate 6 is installed on the first pulley 4, and a hinge 7 is installed on the first slide plate 6 for The limit mechanism 8 of the limit shoe mold, the first limit plate 9 is installed on one side of the first slide plate 6, and the second piston 14 is installed on the side of the first limit plate 9 close to the first slide plate 6 A second piston shaft 15 is installed on the side of the second piston 14 away from the first limiting plate 9, and a second limiting plate 17 is installed on the side of the second piston shaft 15 away from the second piston 14, so A first buffer plate 18 is installed on the side of the second limiting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com