Smashing device used for manufacturing renewable sponge

A pulverizing device and sponge technology, applied in the field of mechanical equipment, can solve the problems of aggravating environmental pollution, polluting the site environment, reducing production efficiency, etc., and achieving the effects of high efficiency, environmental protection and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

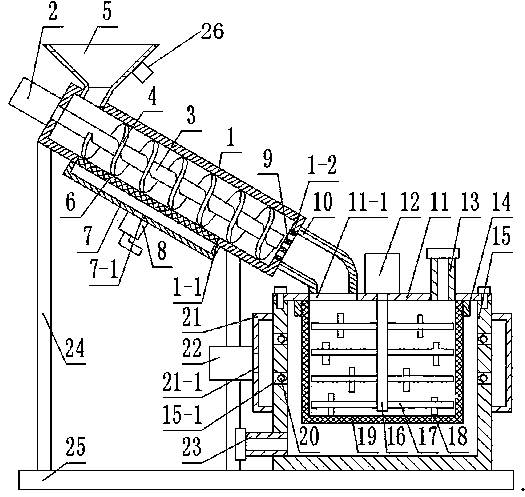

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0013] like figure 1 As shown, a crushing device for making regenerated sponges includes a bottom plate 25, a cylinder 1 is provided on the top surface of the bottom plate 25, and the cylinder 1 is inclined downward. A plurality of supporting cylinders 24, a motor A2 is fixed on the side of the cylinder 1, the driving end of the motor A2 extends into the cylinder 1, the driving end of the motor A2 is fixedly connected with a rotating shaft 3, and the rotating shaft 3 is fixed with a helical blade 4, the top surface of the cylinder 1 is fixed with a funnel 5, the bottom surface of the cylinder 1 is provided with a square through hole 1-1, and the square through hole 1-1 is fixed with a Filter screen 6, described square through-hole 1-1 external cover is provided with the cover body 7 that is fixed on cylinder body 1 bottom surface, and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com