A kind of polishing wheel with handle and its manufacturing tooling and manufacturing method

A polishing wheel and tooling technology, which is applied in the field of polishing, can solve the problems that the metal handle cannot be reused, the manufacturing method is complicated, and the cost is increased, so as to achieve the effects of manufacturing difficulty and cost, reducing procurement cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

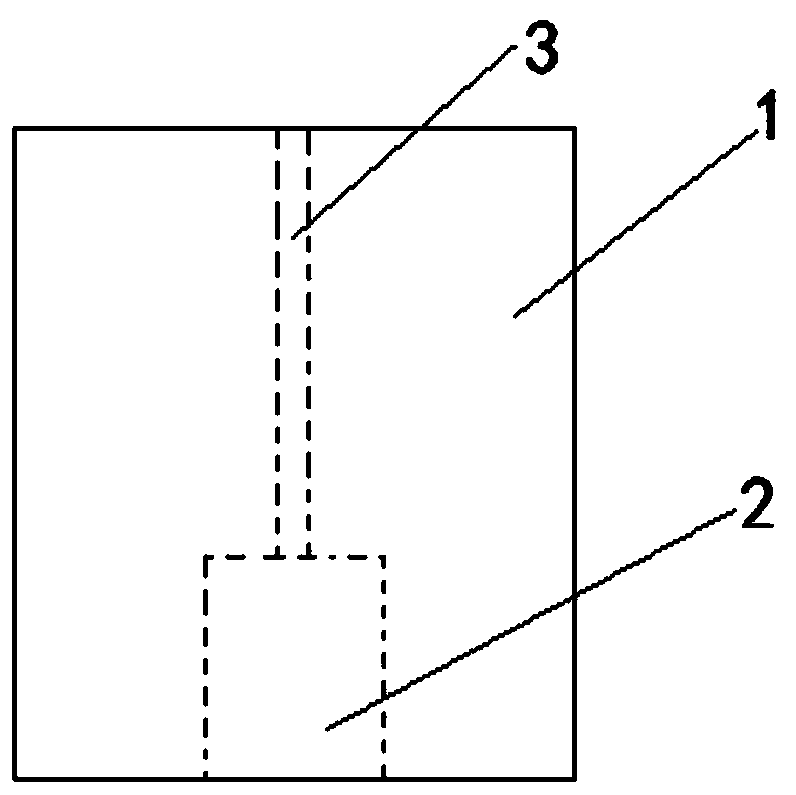

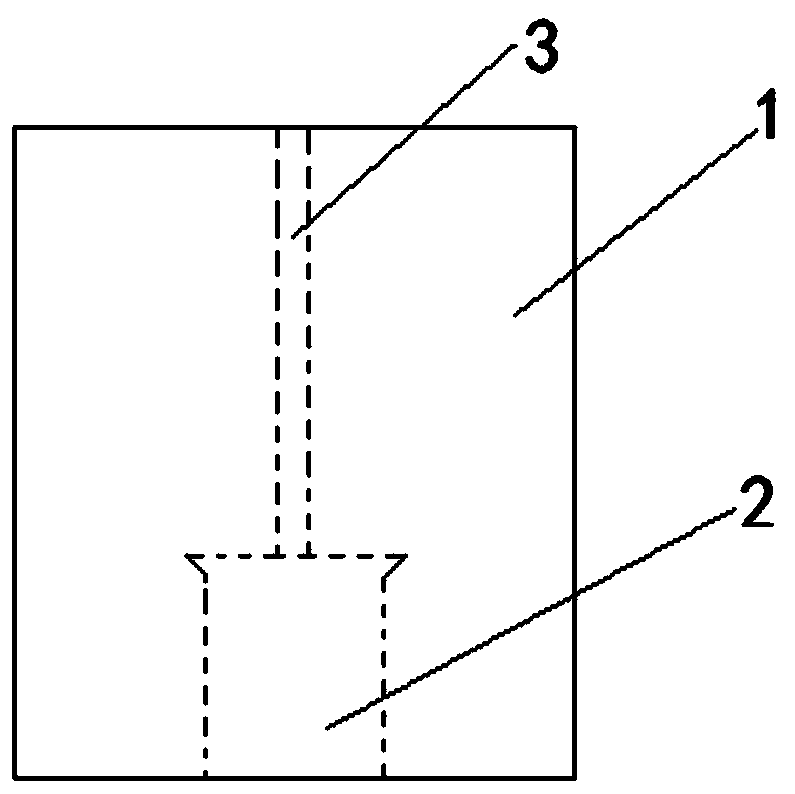

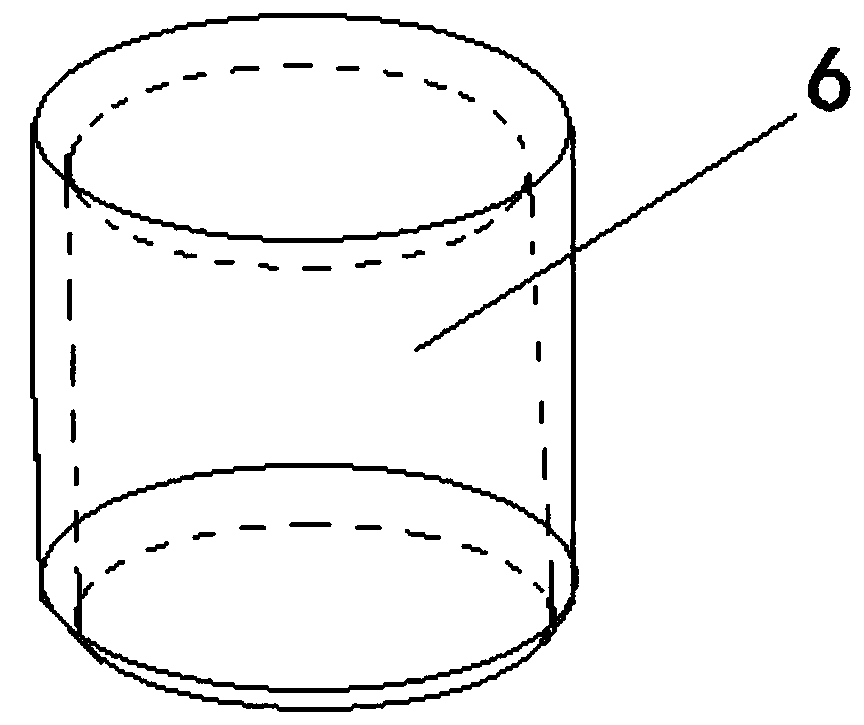

[0033] Such as figure 1 As shown, the tooling for manufacturing the handle polishing wheel according to the present invention includes a tooling body 1, and a second-level stepped hole is arranged in the tooling body 1, and the second-level stepped hole is a through hole, including a first-level hole section whose diameter decreases successively 2 and the secondary hole section 3, the primary hole section 2 and the secondary hole section 3 are coaxially arranged; the primary hole section 2 is used to hold the polishing wheel 4, and its diameter is transitionally matched with the diameter of the polishing wheel 4; the secondary hole The section 3 is used to hold the handle 5 , and its diameter transition fits with the diameter of the handle 5 . The length of the primary hole segment 2 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com