Four-model double-clamp switching sliding table rotary table

A technology with double fixtures and four models, which is applied in the direction of manufacturing tools, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of poor positioning accuracy and low work efficiency, and achieve reduced waiting time, stable equipment operation, and high repeat positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

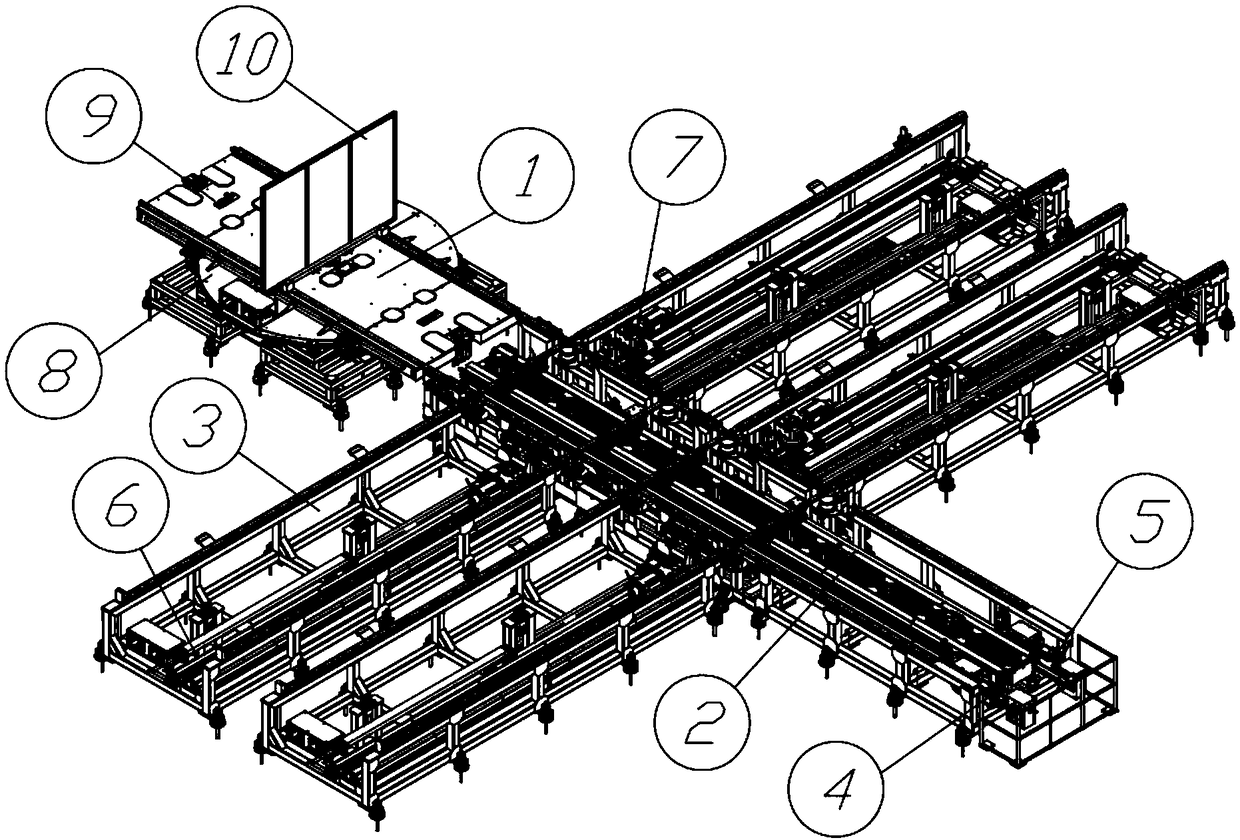

[0018] Such as figure 1 As shown, a four-vehicle double-fixture switching slide table turntable includes a turntable 1, a main slide table 2 and a storage warehouse 3, wherein the turntable 1 is arranged at one end of the main slide table 2 and is connected to the main slide table 2, and the main slide table 2 is connected to the main slide table 2. The upper end of slide table 2 and the opposite side of turntable 1 are provided with main slide table drive motor a4 and main slide table drive motor b5, said main slide table drive motor a4 and main slide table drive motor b5 are used to pull the fixture to the switching position or turntable position , the left and right sides of the main slide 2 are respectively provided with a number of storage warehouses 3 for storing fixtures, and each storage warehouse 3 on the left and right sides of the main slide 2 is respectively provided with a storage library drive motor a6 and a storage library drive The motor b7, the storehouse driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com