Special processing machine and processing method for auto decelerator shell

A technology for reducer housings and automobiles, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc. It can solve the problems of unstable parts quality, poor verticality, and high skill requirements for debugging personnel, so as to reduce the difficulty of debugging and improve The effect of stability and debugging process is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

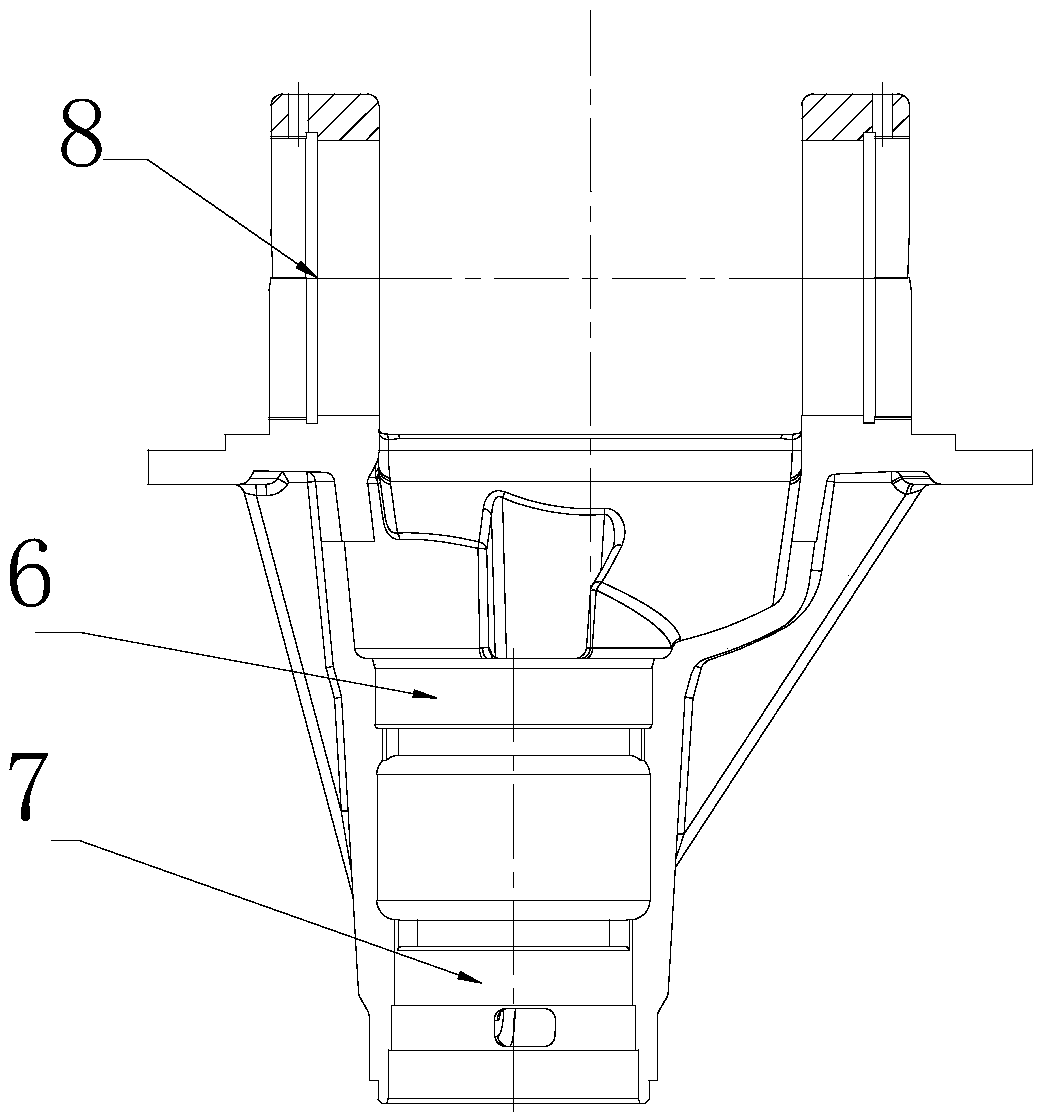

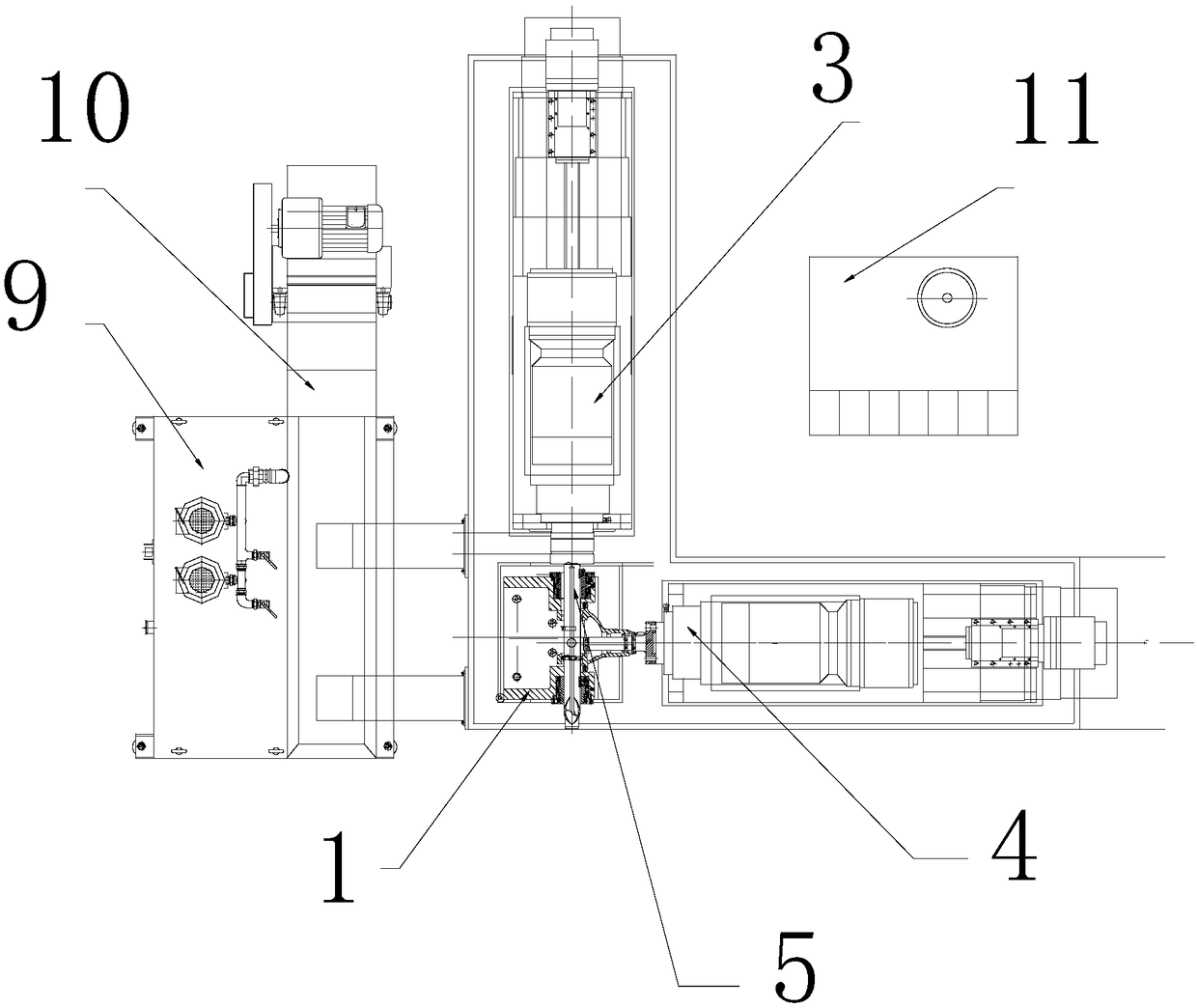

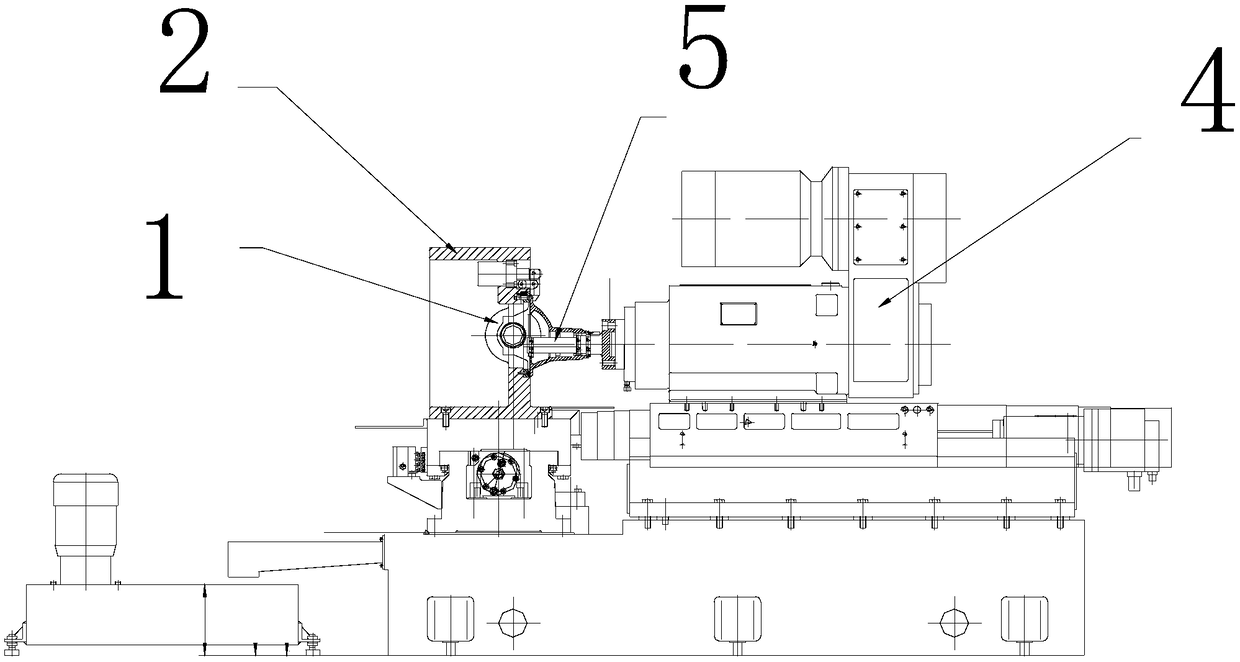

[0021] The structure of the parts of the reducer housing is as follows: figure 1 shown. Such as figure 2 with image 3 As shown, the special double-head boring machine for automobile reducer housing of the present application includes a workpiece fixture 2, a horizontal slide table, a vertical slide table, a horizontal boring processing head 3 and a longitudinal boring processing head 4, and the horizontal boring processing head The axis of 3 is perpendicular to the axis of the longitudinal boring processing head 4, the horizontal boring processing head 3 is installed on the horizontal sliding table, the longitudinal boring processing head 4 is installed on the longitudinal sliding table, the horizontal boring processing head 4 The processing head 3 includes a drive motor and a cutter bar 5 that is transmission-connected with the output shaft of the drive motor. The fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com