Ore pulp thickening and dewatering method and device

A technology for concentration, dehydration and ore pulp, which is applied in cyclone devices, separation methods, chemical instruments and methods, etc., can solve problems such as the deterioration of fine particle sedimentation, and achieve the effect of eliminating vicious circle, simplifying filling process, and promoting application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the present invention is not limited to the examples.

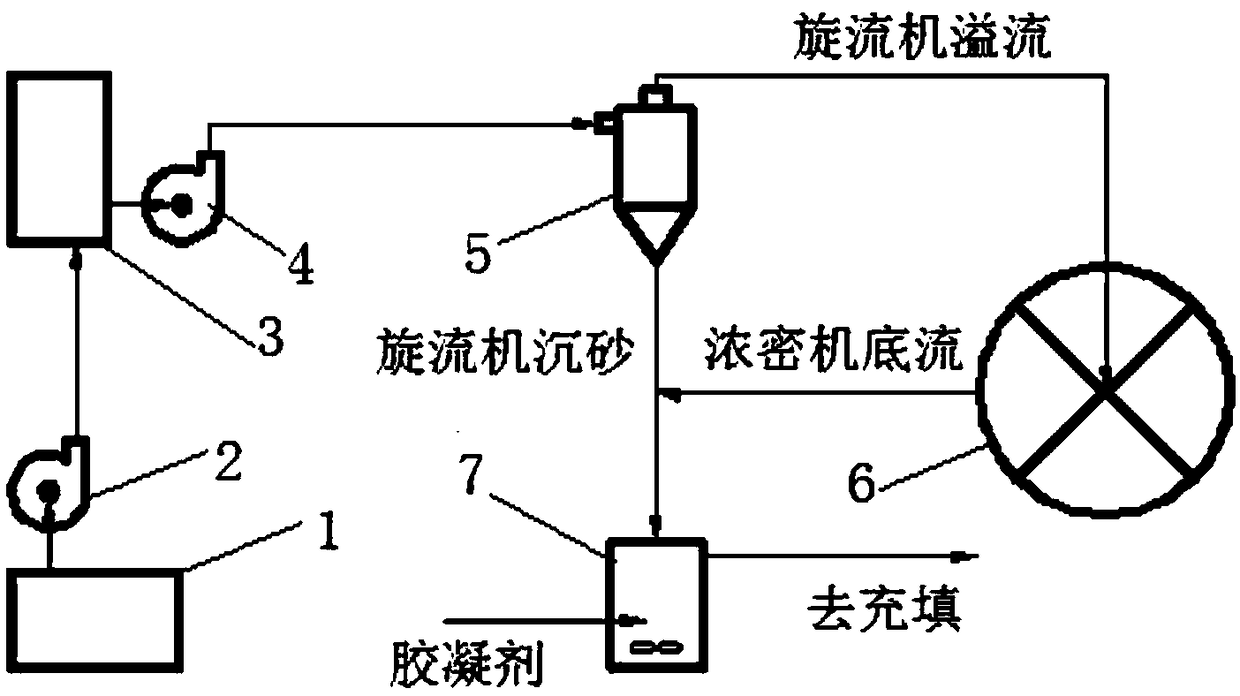

[0020] Such as figure 1 As shown, the present invention is applied to the concentration and dehydration of tailings mixed in mine filling. The tailings slurry concentration and dehydration device includes a tailings pump pool 1, a tailings sand pump 2, a cyclone feeding pump pool 3, and a cyclone feeding pump 4. A cyclone 5, a thickener 6, and a high-concentration mixing tank 7, wherein the cyclone 5 is connected to the thickener 6 and the high-concentration mixing tank 7 respectively.

[0021] The tailings slurry produced by the concentrator after crushing, grinding and sorting is collected in the tailings pump pool 1 and sent to the cyclone feeding pump pool 3 by the tailings sand pump 2; The ore pump 4 lifts the tailings slurry to the cyclone 5 for controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com