Dismountable semi-automatic water-bath vibrating evaporating device

An evaporator, semi-automatic technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of low evaporation efficiency, low evaporation efficiency of experimental products, waste of time, etc., and achieve large heating area and evaporation area , easy and convenient cleaning, and the effect of improving evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

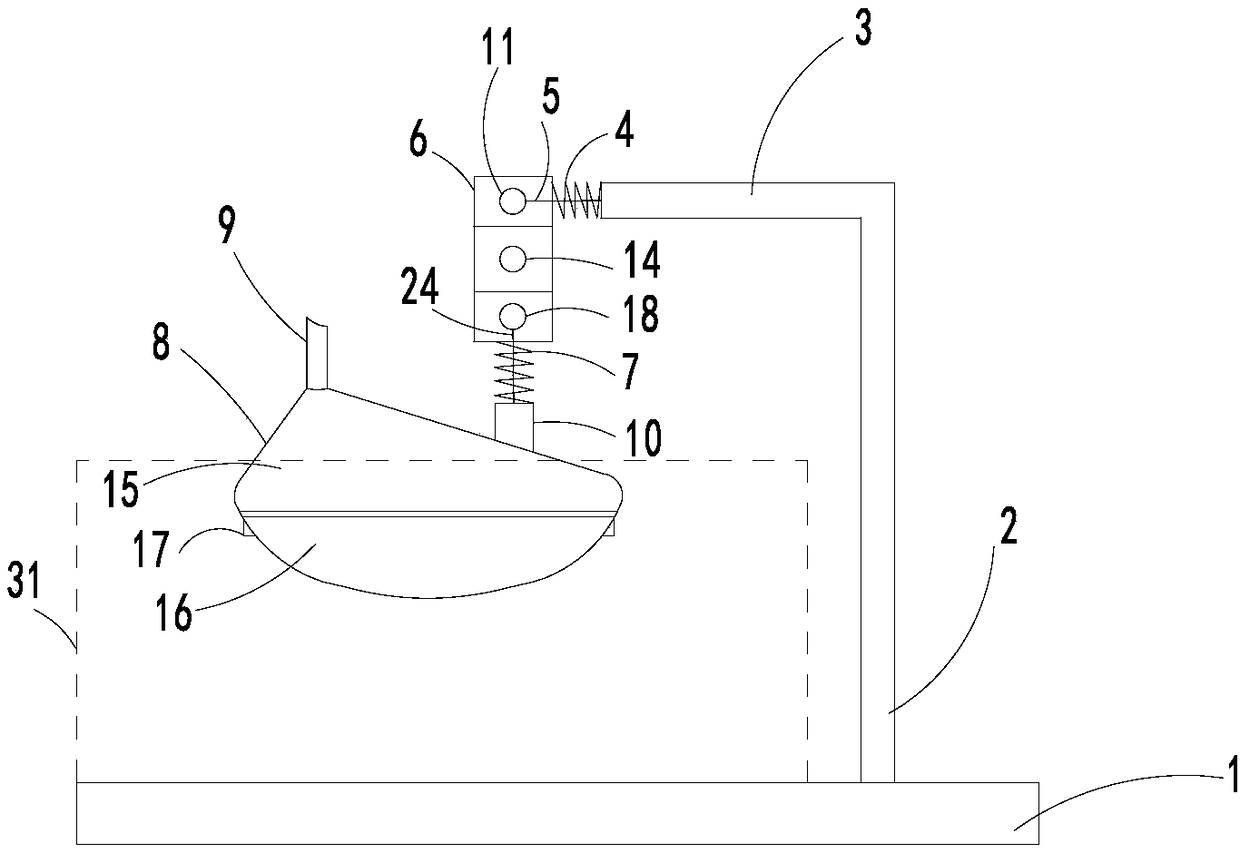

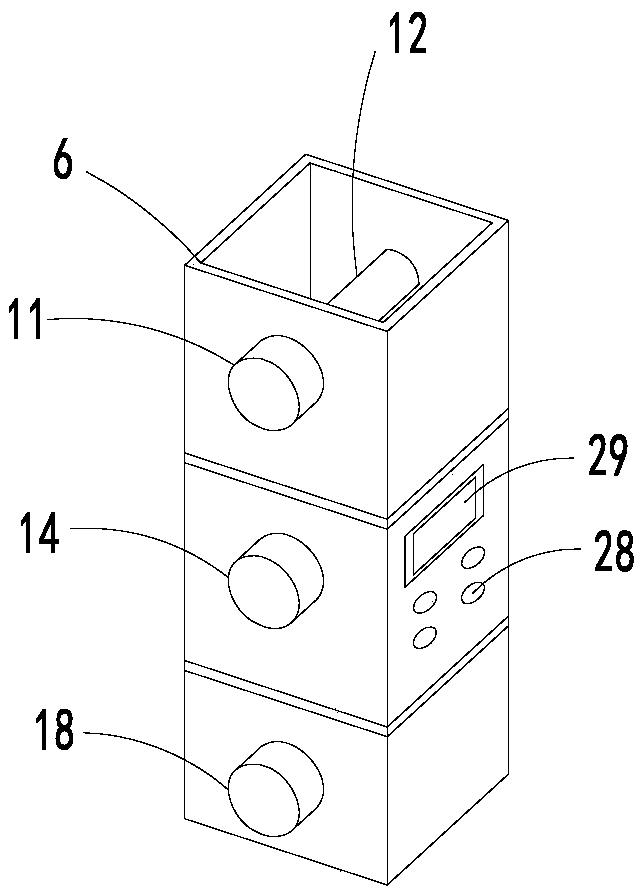

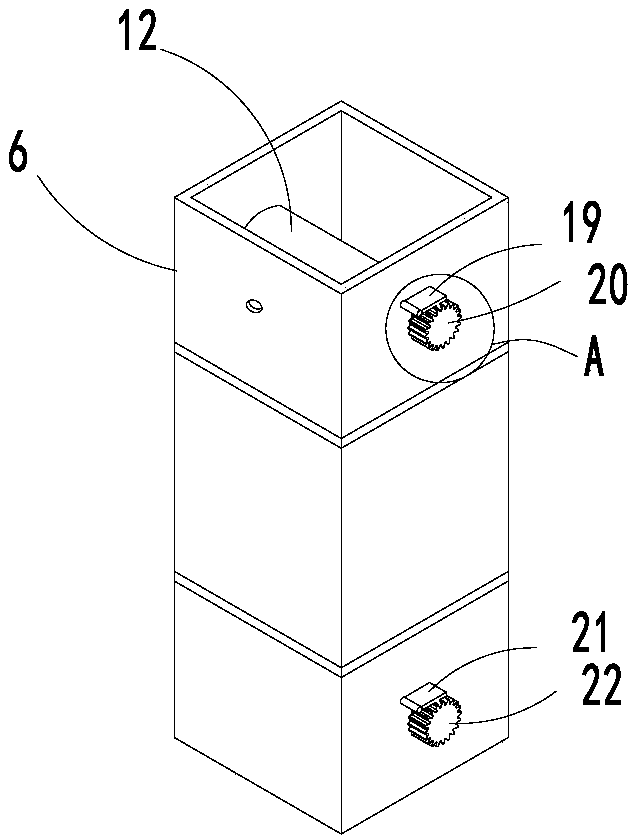

[0036] In order to understand the present invention better, below in conjunction with appendix Figure 1-10 Embodiments of the present invention will be explained in detail.

[0037] The invention comprises a stand and a container bottle 8 comprising a connection end 10 and an air outlet end 9 . The support includes a base 1 and a support rod 2 vertically fixed on the base 1 , and a cross bar 3 is connected to the upper end of the support rod 2 . In order to enable the container bottle 8 to vibrate, a thick spring 4 is arranged on the cross bar 3, a free end of the thick spring 4 is connected to the cross bar 3, and the other free end of the thick spring 4 is fixedly connected to a vibrating part 6. The thick spring 4 is softly connected with the cross bar 3 to realize the vibration of the container bottle 8 . There are two ways to set up the thick spring 4, such as figure 1 As shown in , the first setting mode of the thick spring 4 is horizontal setting. Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com