Drying device and method of use thereof

A technology of drying device and installation part, which is applied in the fields of application, food science, food processing, etc. It can solve the problem of damage to the molecular and intermolecular sealing of pressed meal particles, the inability to maintain compaction and compaction of pressed meal, the uniformity or thickness of meal feed Large differences and other problems, to achieve the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

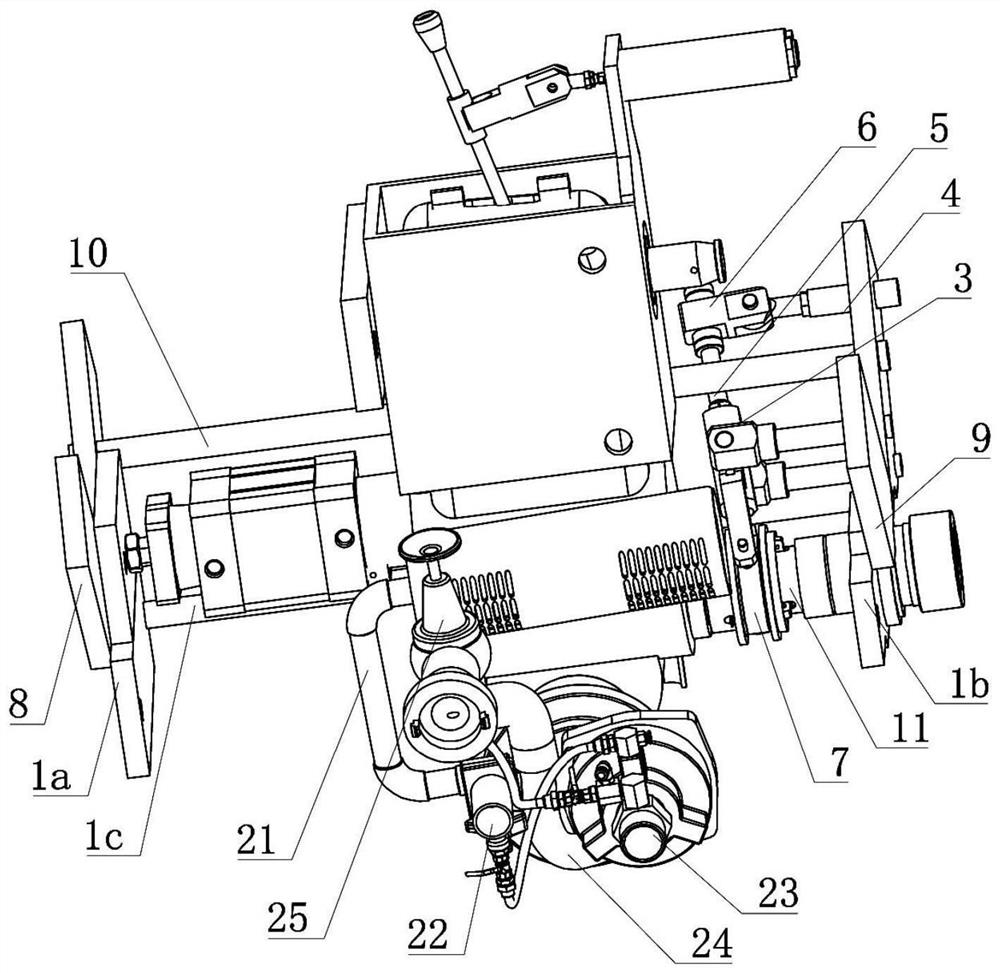

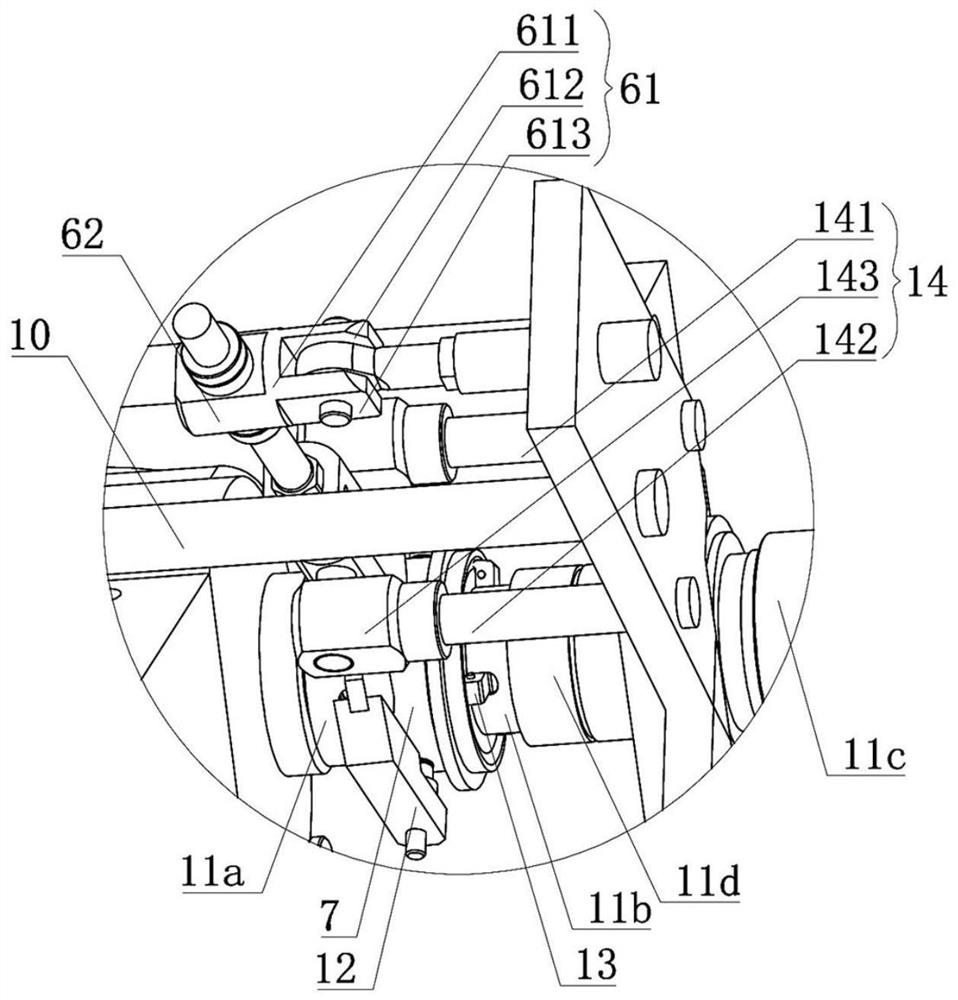

Embodiment 1

[0037] The drying device includes an installation part 1, an air-drying mechanism 2 arranged on the installation part 1, and an adjustment mechanism 3 for adjusting the air outlet angle of the air-drying mechanism 2. The adjustment mechanism 3 includes a driving drive rod 4 and a driven drive rod 5 for Hinge 6 connecting active driving rod 4 and driven driving rod 5, sliding sleeve 7, left rocking plate 8, right rocking plate 9, rocking connecting rod 10, first rotating shaft 11, positioning bracket 14, rocking connecting rod 10 The left and right ends are respectively connected to the left wobble plate 8 and the right wobble plate 9, the active drive rod 4 is connected to the driven drive rod 5, and the bottom of the driven drive rod 5 is provided with a drive connecting rod 12 for connecting the sliding sleeve 7, and the first rotating shaft 11 includes a first part 11a of the rotating shaft and a second part 11b of the rotating shaft which are independently arranged, the fir...

Embodiment 2

[0040] The drying device includes an installation part 1, an air-drying mechanism 2 arranged on the installation part 1, and an adjustment mechanism 3 for adjusting the air outlet angle of the air-drying mechanism 2. The adjustment mechanism 3 includes a driving drive rod 4 and a driven drive rod 5 for Hinge 6 connecting active driving rod 4 and driven driving rod 5, sliding sleeve 7, left rocking plate 8, right rocking plate 9, rocking connecting rod 10, first rotating shaft 11, positioning bracket 14, rocking connecting rod 10 The left and right ends are respectively connected to the left wobble plate 8 and the right wobble plate 9, the active drive rod 4 is connected to the driven drive rod 5, and the bottom of the driven drive rod 5 is provided with a drive connecting rod 12 for connecting the sliding sleeve 7, and the first rotating shaft 11 includes a first part 11a of the rotating shaft and a second part 11b of the rotating shaft which are independently arranged, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com