A fungus culture device for cultivation of edible fungus bag materials

A technology of bacterial culture and bag material, applied in cultivation, plant cultivation, mushroom cultivation and other directions, can solve the problems of bacterial contamination by bacteria, high labor intensity, low degree of automation, etc., to avoid damage or bacterial pollution, reduce personnel The effect of labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

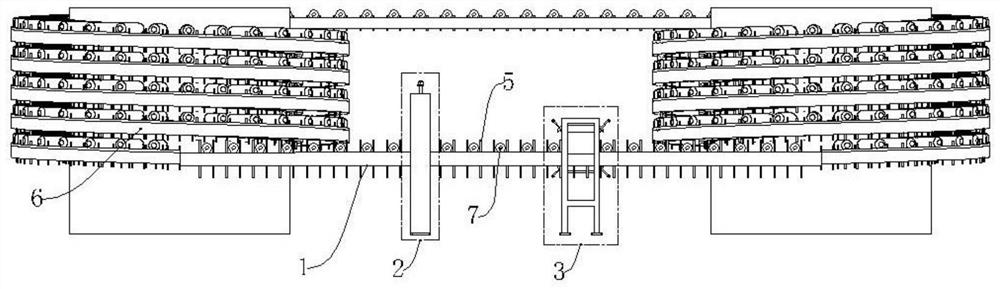

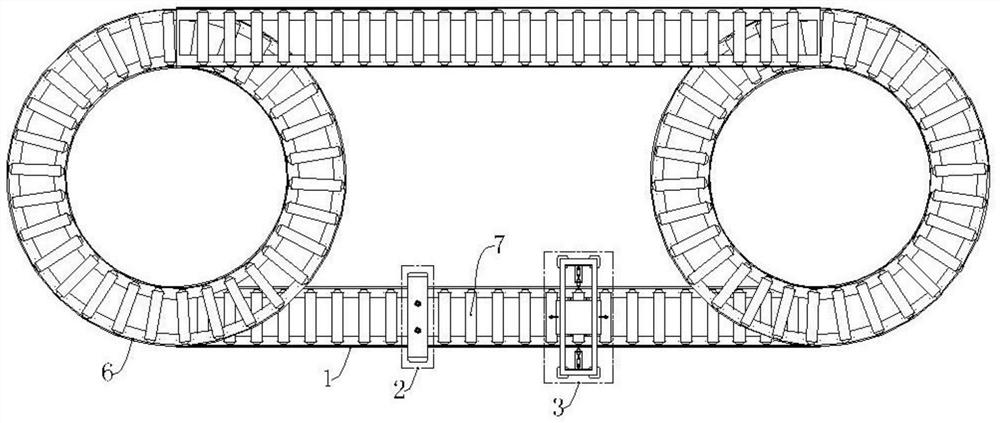

[0024] Figure 1 to Figure 5 It shows the fungus culture device of the mushroom bag material cultivation of the present invention, and the hair fungus culture device of the mushroom bag material cultivation of the present invention is arranged in the hair fungus cultivation room, including chain plate conveyor, single-directional punching device 2 and multi-directional Piercing device 3.

[0025] The chain plate conveyor includes a spiral conveying section 6 and a horizontal conveying section 1. The spiral conveying section 6 is provided with multiple layers along the vertical direction. There are two spiral conveying sections 6. The head end and tail end of the two spiral conveying sections 6 are respectively Two horizontal conveying sections 1 are connected to form a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com