Double-strip winding technology

A tape and winding technology, used in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problem of inability to judge the middle position of the outer protective tape wrapping gap, and achieve convenient wrapping effect, convenient detection, and improvement protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

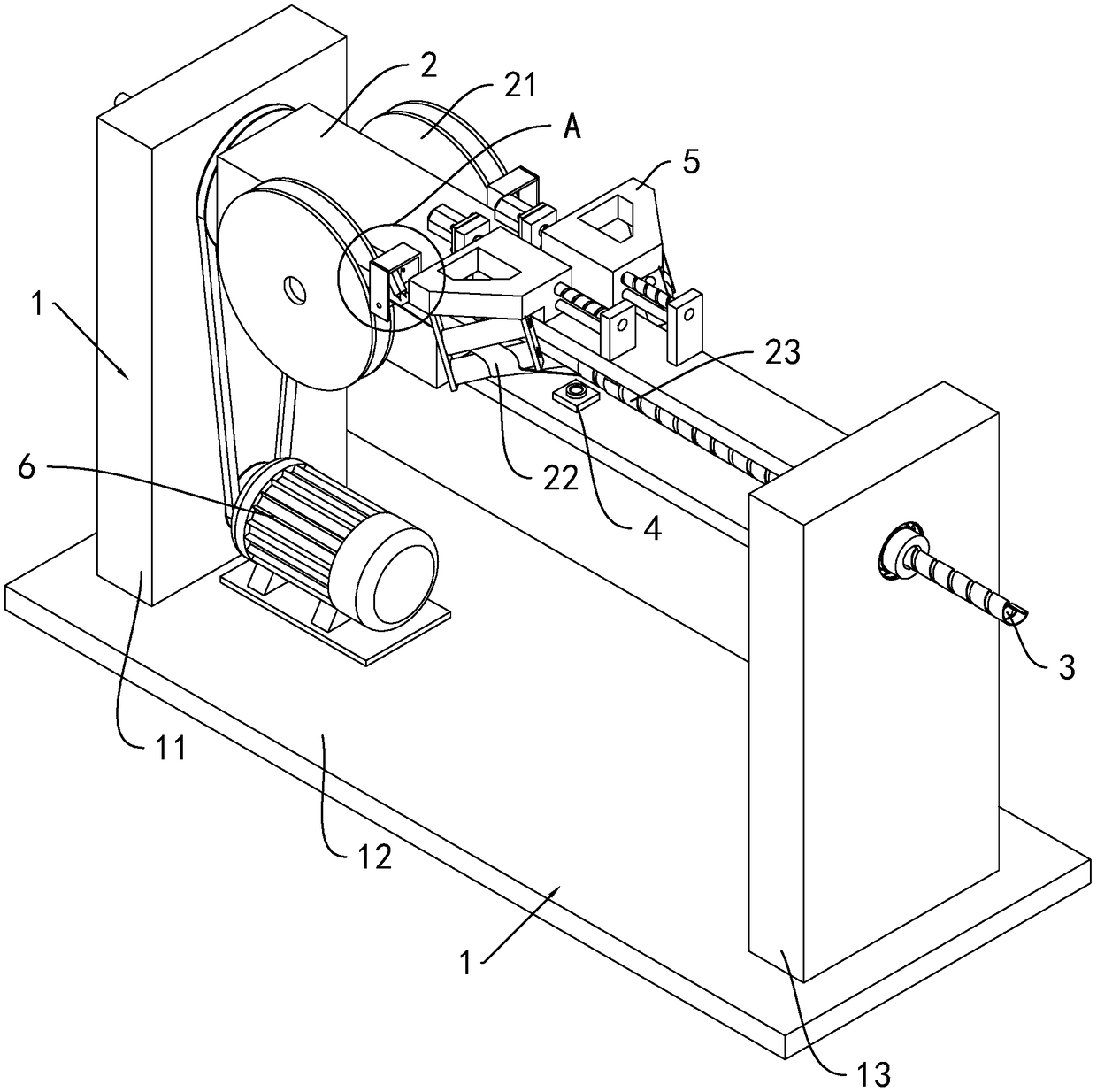

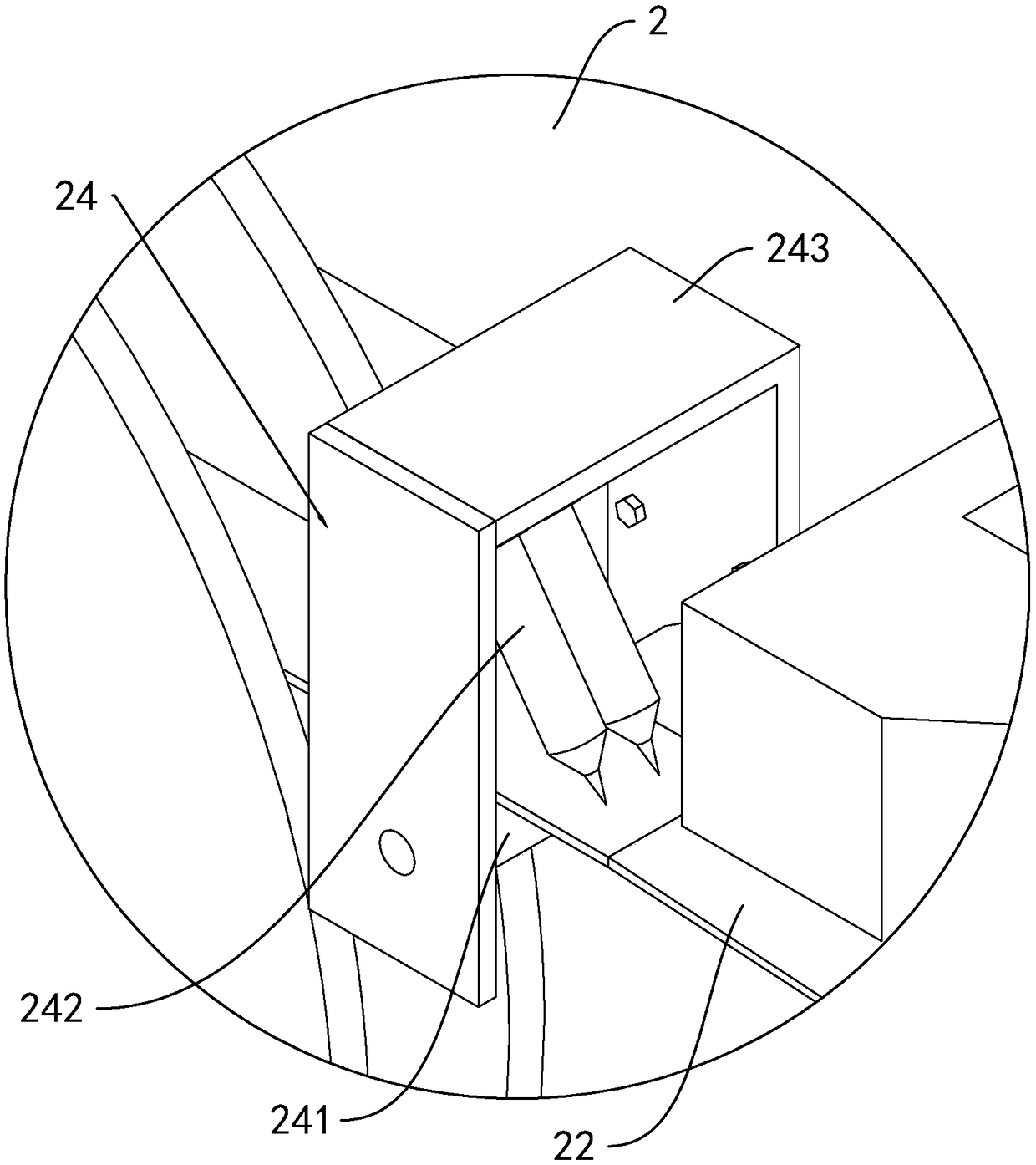

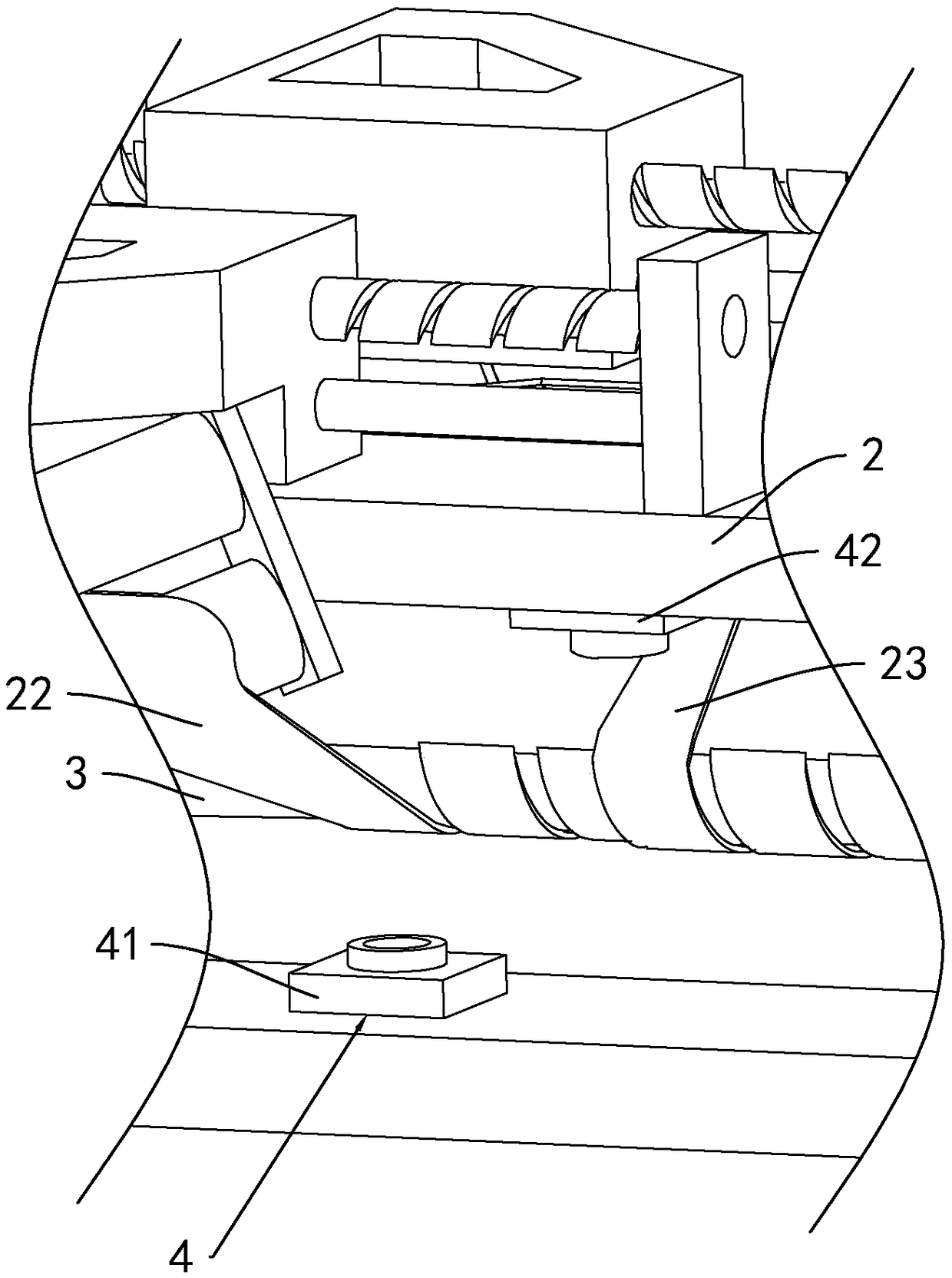

[0039] Embodiment 1: a kind of cable armoring machine, such as figure 1As shown, it includes a frame 1, a turret 2, a detection device 4, a deviation correction device 5 and a driving structure; the frame 1 includes a base 12, a front support frame 11 and a rear support frame 13, and the front support frame 11 and the rear support frame 13 are respectively The left and right ends of the base 12 are fixedly connected. The two ends of the turret 2 are rotatably connected to the front support frame 11 and the rear support frame 13 respectively, and the cables 3 to be armored pass through the front support frame 11, the turret 2 and the rear support frame 13 successively from the left, and are then wound up on the On the winding device (not shown in the figure), the winding device rotates to move the cable 3 axially, wherein the cable 3 and the turret 2 are arranged coaxially. Two tape reels 21 are rotatably connected to both sides of the turret 2 . The two tape reels 21 are coax...

Embodiment 2

[0045] Embodiment 2: a kind of double-strip material winding process, concrete steps are as follows:

[0046] Step S1: threading the cable 3, putting the cable 3 on the armoring machine, winding one end of the cable 3 on the winding device, and winding the cable 3 when the winding device starts, so as to exert a pulling force on the cable 3, so that The cable 3 slowly passes through the armoring machine.

[0047] Step S2: Fix the inner layer protective tape 22, pass one end of the inner layer protective tape 22 through the guide belt device 24 and the deviation correction device 5 and then fix it to one end of the cable 3, and form an angle between the inner layer protective tape 22 and the cable 3 , so that when the inner layer protection tape 22 is wrapped around the cable 3, the wrapping angle is formed; then the armoring machine is started slowly, so that the inner layer protection tape 22 gap is wrapped around the cable 3; the inner layer protection tape 22 and the cable ...

Embodiment 3

[0055] Embodiment 3: a cable 3 armoring process, the difference from Embodiment 2 lies in step S2, step S4 or step S5.

[0056] The marking lines in step S2 are marking lines drawn on the surface of the inner protective tape 22 with a water-based pen, and the distance between the two marking lines is greater than the wrapping gap of the outer protective tape 23 .

[0057]When observing whether the outer layer protection tape 23 meets the requirements in step S4, when the marking line on the left side is not blocked by the outer layer protection tape 23, it means that the outer layer protection tape 23 is shifted to the left; When the outer protective tape 23 is blocked, it means that the outer protective tape 23 is shifted to the right; The quality of the armored cable 3 is judged, and the step S5 does not need to remove the marking line, which reduces working steps and makes the armoring process simpler and more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com