Vulcanized busbar lapping surface cutting device and vulcanized busbar lapping surface cutting method

A busbar lap and busbar technology, used in electrical components, circuits, and conductor/cable insulation, etc., can solve the problems of easily damaged tin plating on the lap surface, low efficiency, etc., to achieve high removal efficiency and easy production. The effect of simple processing and transmission form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

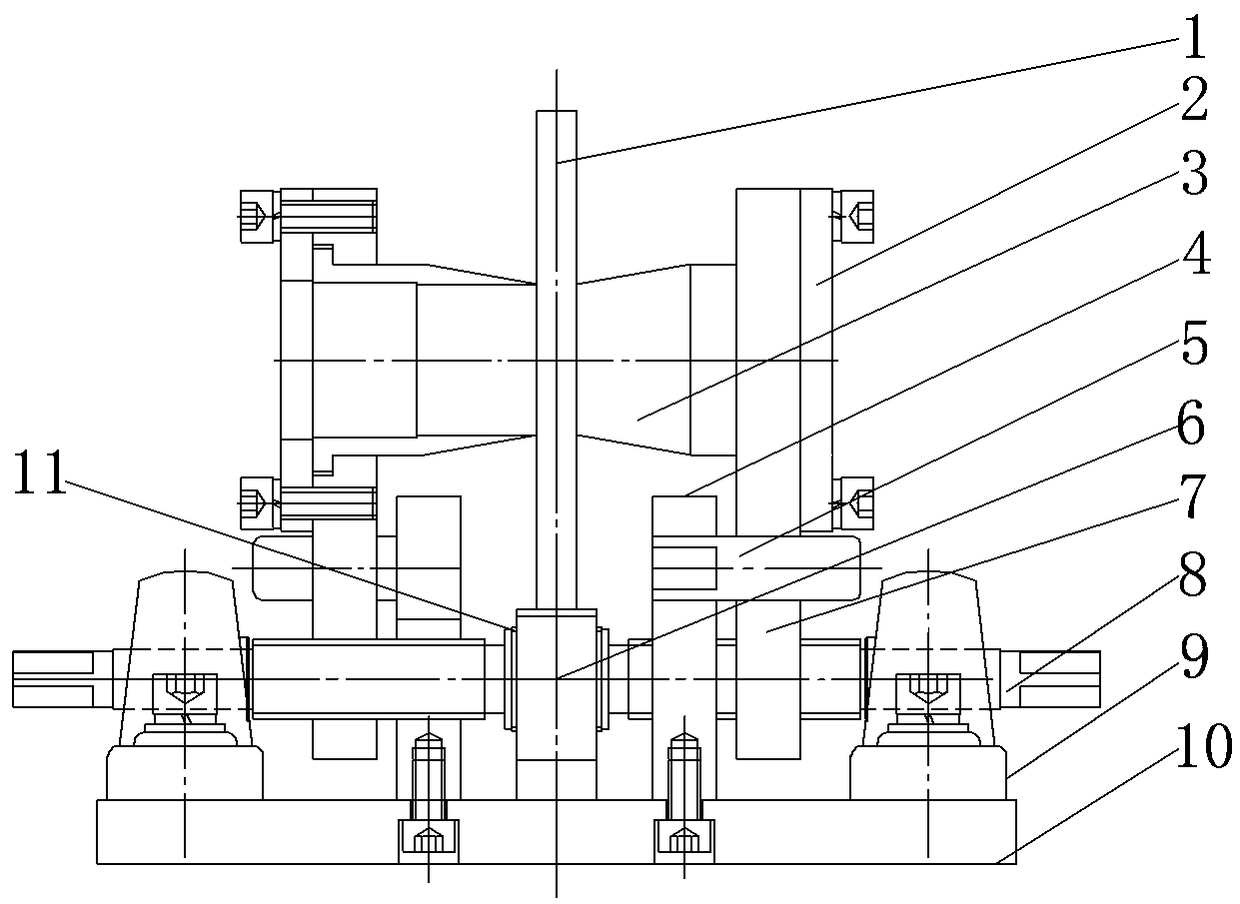

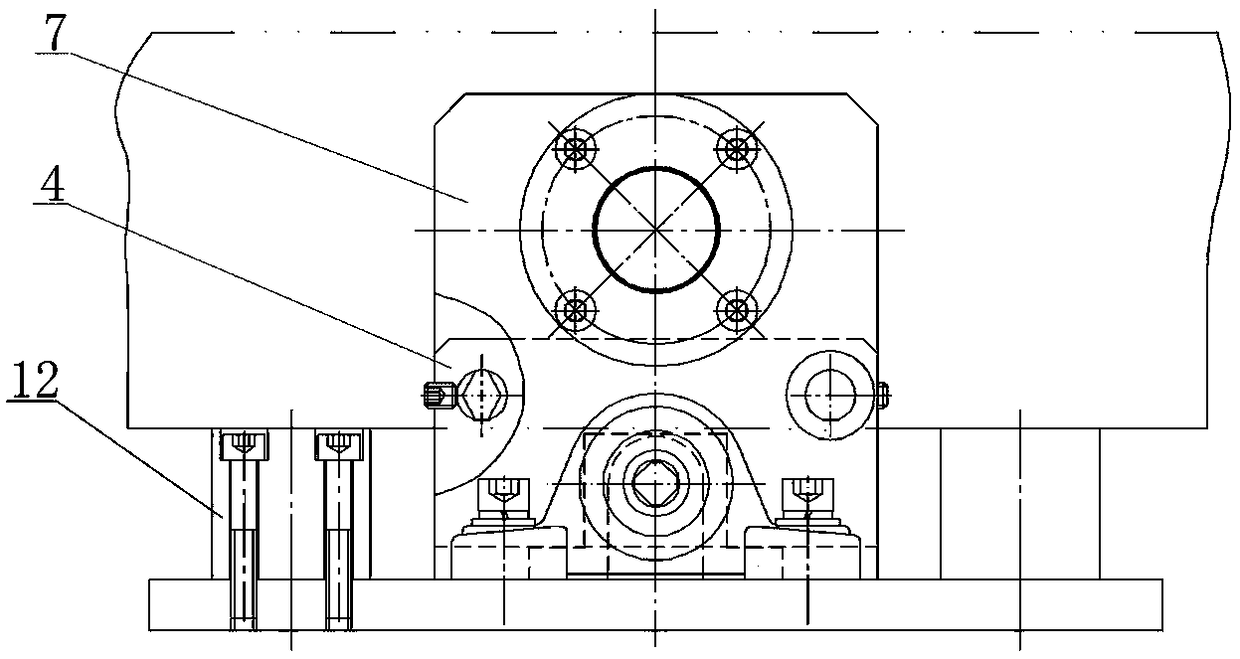

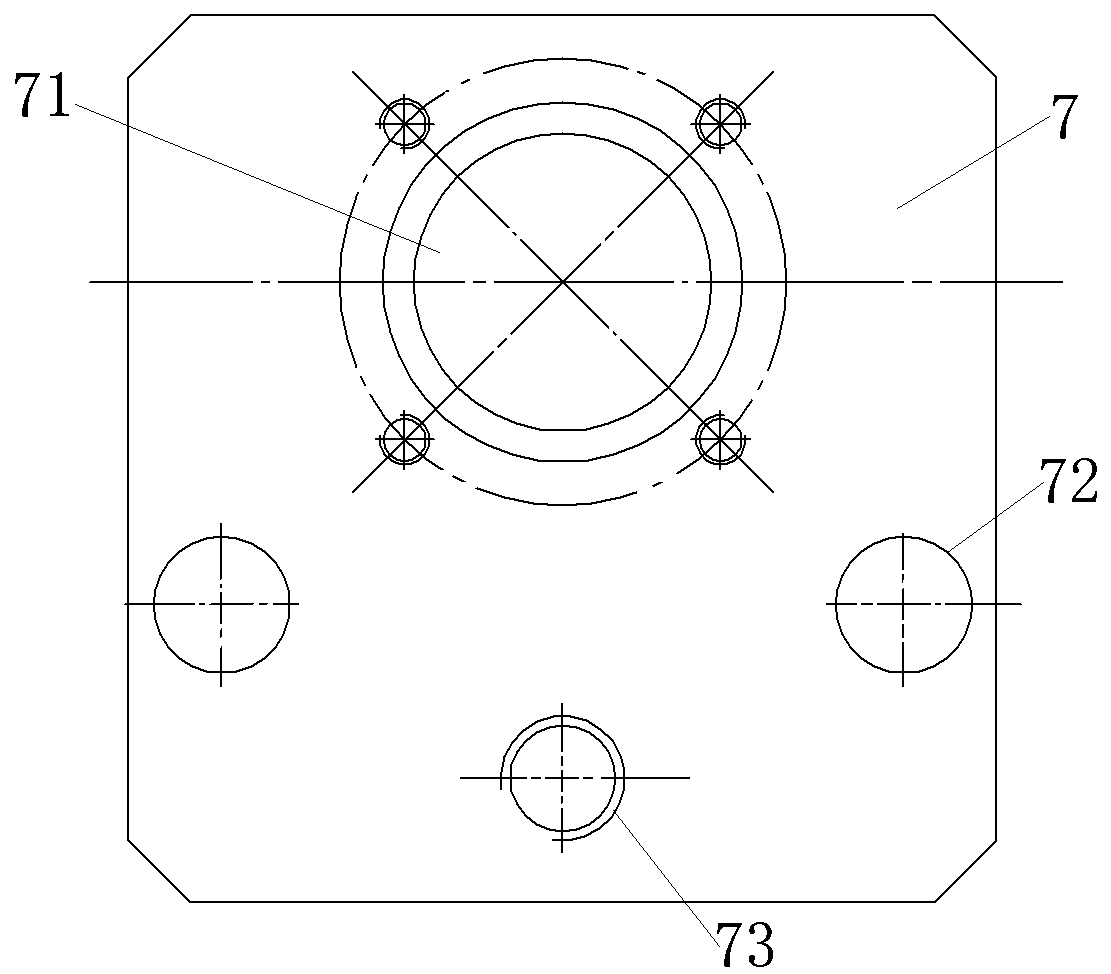

[0031] Embodiment 1 of the cutting device for the overlapping surface of the vulcanized busbar of the present invention is as follows: Figure 1 to Figure 8 As shown, the cutting device for the overlapping surface of the vulcanized busbar includes a base 10, and the base 10 is provided with a busbar mounting seat 12 for installing the vulcanized busbar 1, and both sides of the busbar mounting seat 12 are provided with cutter devices, The cutter device includes a cutter base 4, a cutter holder 7 and a cutter, the cutter 3 is fixed on the cutter holder 7, the cutter holder 7 is guided and assembled on the cutter base 4, the cutter 3 has an annular blade, and the positions of the two cutters correspond to each other. It is provided that the cutter 3 is connected with a driving device for driving the two cutters 3 to move towards each other.

[0032] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com