Liquid droplet measurement method, liquid droplet measurement device, and method and apparatus for manufacturing device

A measuring device and a measuring method technology, which are applied in the field of device manufacturing devices, and can solve problems such as difference in film thickness of functional materials, uneven brightness, and defective devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

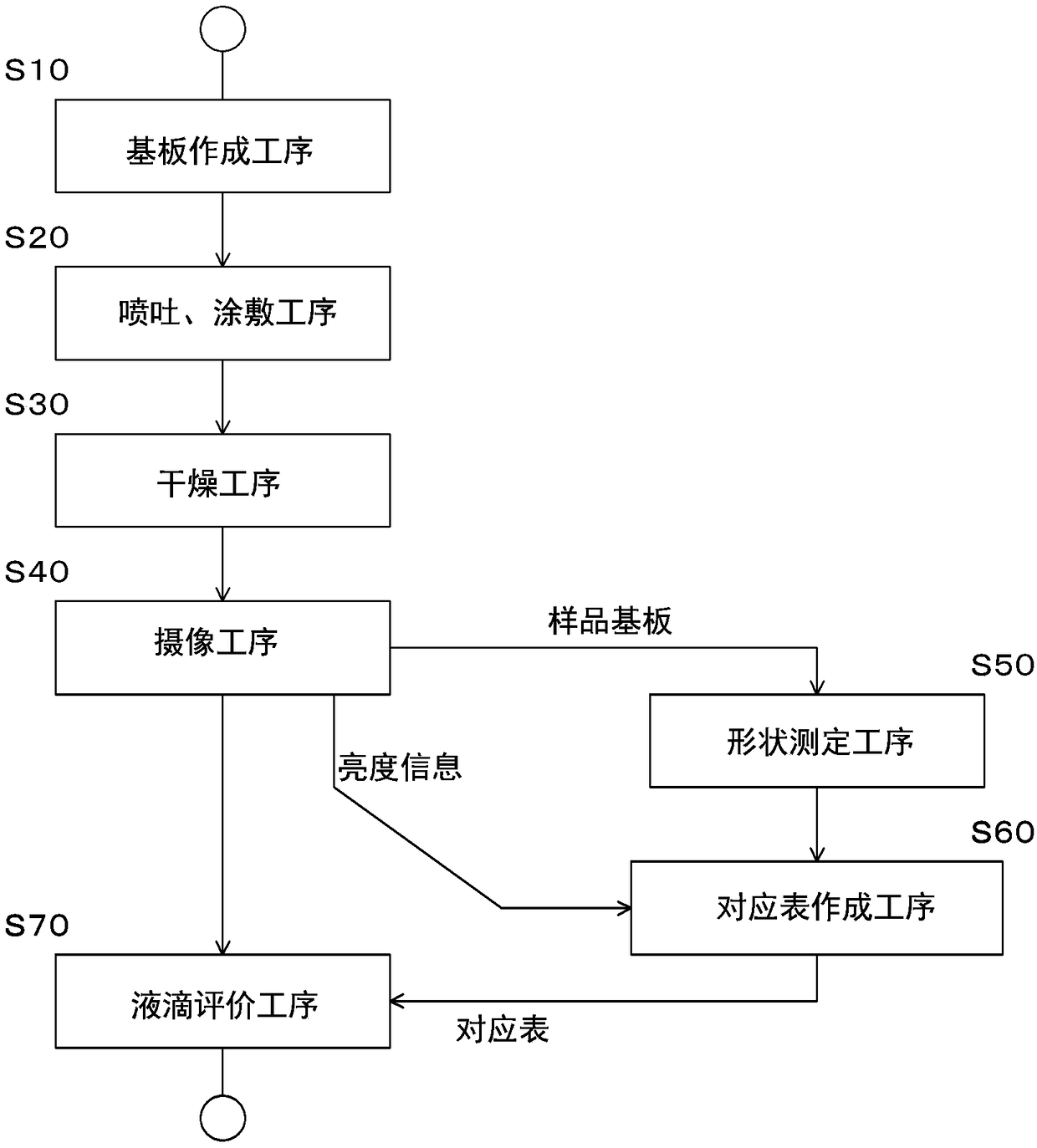

[0086] figure 1 A panel manufacturing apparatus including a droplet measurement device for carrying out the droplet measurement method of the present invention is shown. The panel manufacturing device includes a droplet discharge device 1 , a droplet measurement device 2 , a decompression chamber 3 , and a droplet shape measurement device 4 .

[0087] The decompression chamber 3 is used when drying the applied liquid droplets. The droplet measurement device 2 obtains the volume or surface shape of the droplet 30 in a short time based on brightness information obtained by imaging the droplet 30 discharged onto the sample substrate 19 by the droplet discharge device 1 . This result is fed back to the droplet discharge device 1, so that the subsequent droplet discharge operation is brought closer to the target state.

[0088] The droplet shape measuring device 4 provided independently from the droplet measuring device 2 is a device for creating a correspondence table between th...

Embodiment approach 2

[0193] In Embodiment 1, the droplet measurement device 2 is provided independently of the droplet discharge device 1, but it may also be as Figure 11 Combine like that. Figure 11 It is a perspective view of a droplet discharge device in which the droplet measuring device 2 and the droplet discharge device 1 are integrated.

[0194] In the droplet discharge device 1 , the imaging unit 20 is provided on the support unit 11 . On the production table 8 , a concave portion 44 is formed in the measurement table 21 of the droplet measurement device 2 . Moreover, being able to figure 2 The brightness information of the sample substrate 19 imaged by the imaging unit 20 is processed as shown.

[0195] In the present embodiment, the droplet discharge module head 15 is arranged in the longitudinal direction in the sub-scanning direction of the stage 9 , and therefore, the recess 44 is also preferably provided to be elongated in the sub-scanning direction of the stage 9 .

[0196] I...

Embodiment approach 3

[0199] In Embodiment 1, the case where the printed object 7 created by the liquid droplet discharge device 1 is used as the sample substrate 19 as it is, or the case where the printed object 7 is cut and used as the sample substrate 19 has been described. That is, the case where the sample substrate 19 on which droplets have been printed is set on the measurement stage 21 of the droplet measurement device 2, and a correspondence table is created.

[0200] However, the line head 6 intended to be used in the droplet discharge device 1 can be provided on the side of the droplet measuring device 2 .

[0201] That is, the sample substrate 19 on which the droplet 30 and the dummy droplet 31 are not formed is set on the measurement stage 21 of the droplet measurement device 2 . Thereafter, in the droplet measurement device 2, the droplet 30 and the dummy droplet 31 are printed on the sample substrate 19 corresponding to the position of the concave portion 44 of the measurement table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com