Kitchen ventilator with flow guide component having noise filtration function

A technology for noise filtering and range hood, which is applied in the direction of removing oil fume, parts of pumping device for elastic fluid, pump element, etc. Reduce, reduce specific single frequency noise and broadband noise, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

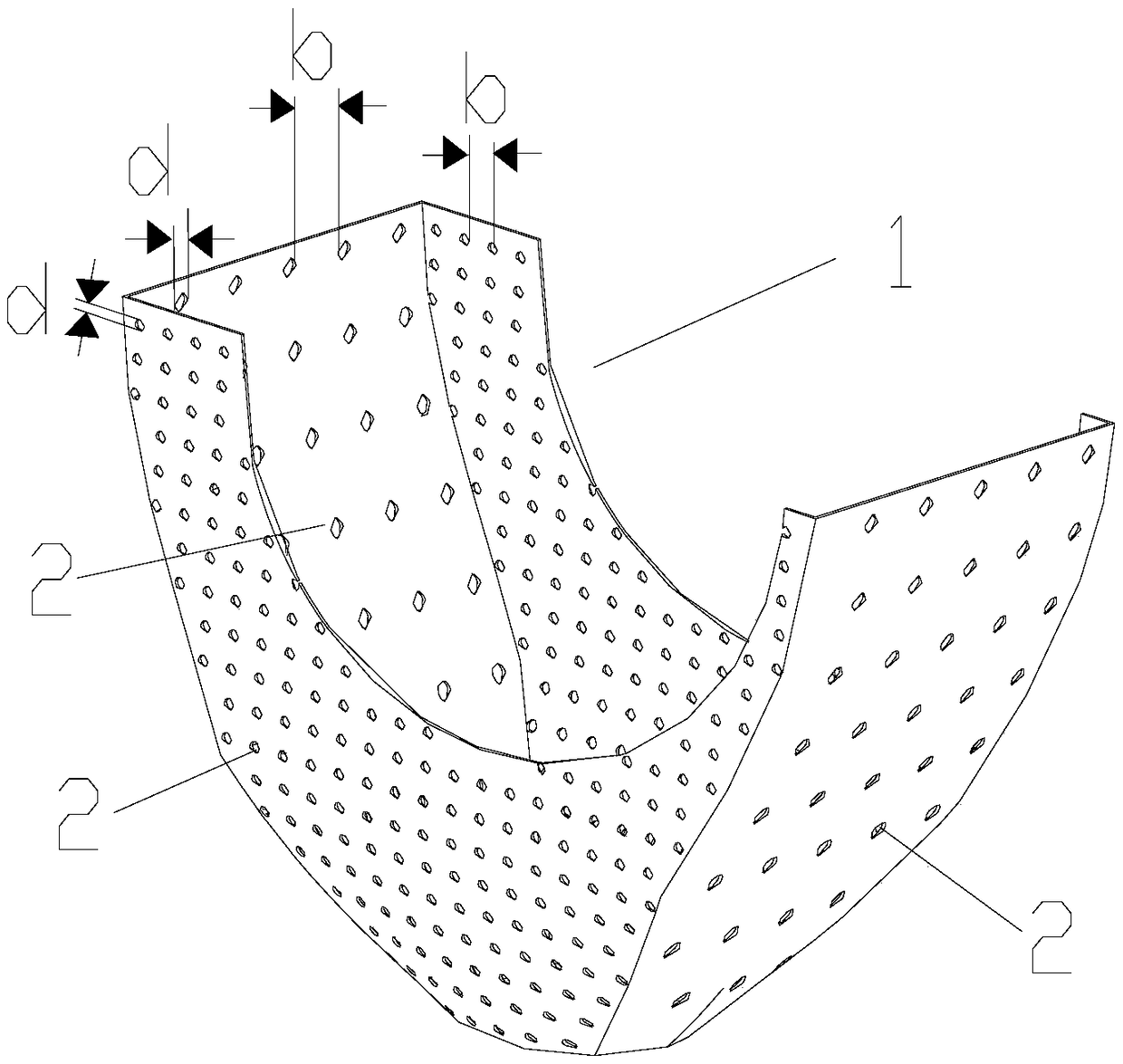

[0042] A range hood with a noise filtering function guide assembly, such as figure 1 As shown, the main body of the hood and the air guide assembly 1 capable of eliminating noise are provided, and the air guide assembly 1 is assembled inside the main body of the hood. The flow guiding component 1 is distributed with a plurality of through holes 2 for eliminating noise.

[0043] The present invention achieves specific single-frequency or specific multi-frequency noise reduction by adjusting the apertures of different through holes 2 , the minimum distance between the edge of a through hole 2 and the edge of an adjacent through hole 2 , or the area distribution of the through holes 2 .

[0044] The diameter of the through hole 2 of the present invention is defined as d, and d≤30mm; wherein d is a plurality of numerical values. The minimum distance between the edge of the through hole 2 and the edge of the adjacent through hole 2 of the present invention is b, where b is any val...

Embodiment 2

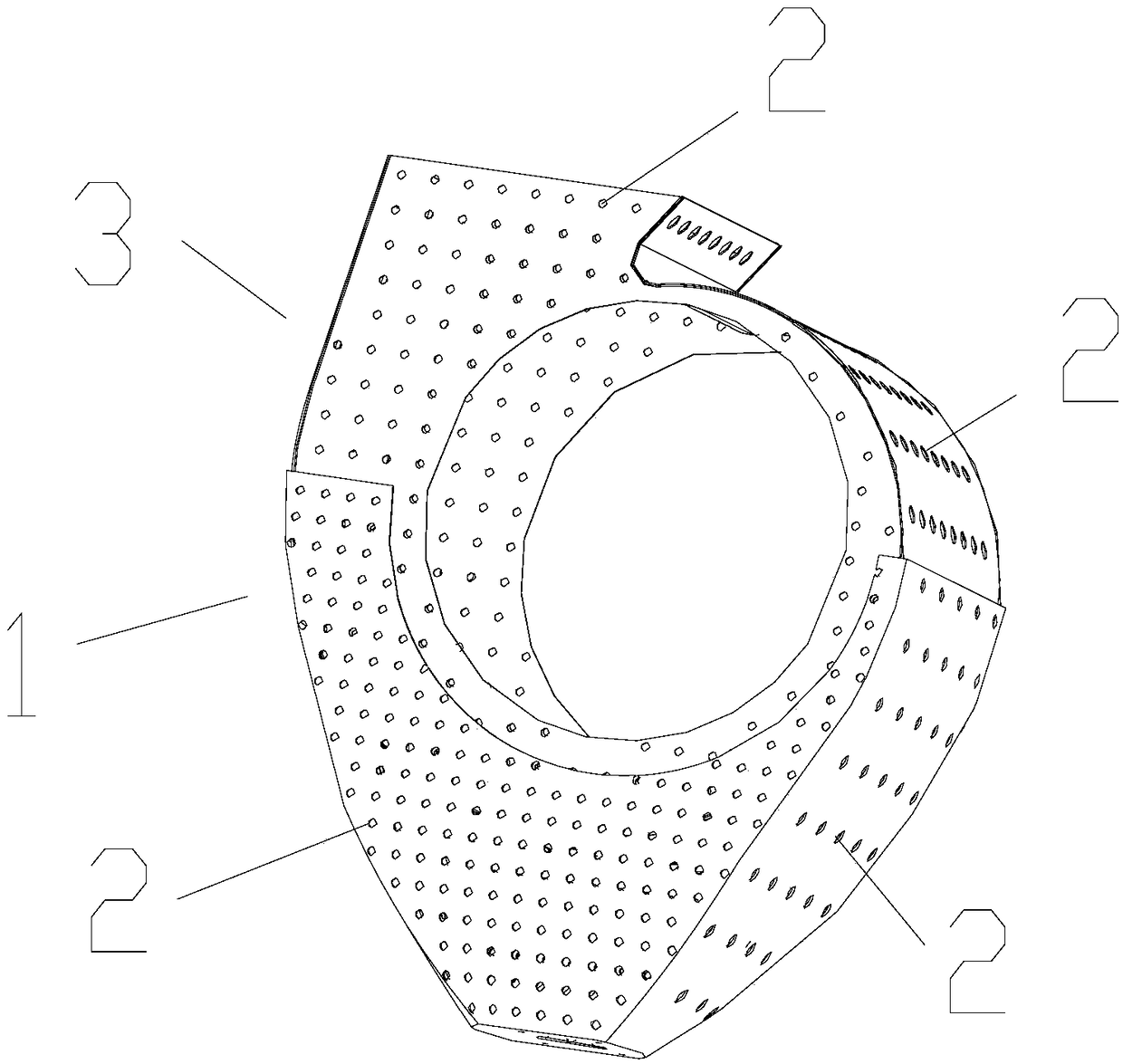

[0055] A range hood with a noise filtering function guide assembly, such as figure 2 and 3 As shown, the other features are the same as those in Embodiment 1, except that: the main body of the range hood is provided with an exhaust assembly, the exhaust assembly is assembled inside the main body of the range hood, and the flow guide assembly 1 is assembled under the exhaust assembly.

[0056] The exhaust assembly is provided with a volute 3 , and the guide assembly 1 is assembled under the volute 3 . The volute 3 is also distributed with a plurality of through holes 2 for eliminating noise.

[0057] The principle of the noise reduction device in this embodiment is as follows: in a limited enclosed space, when the noise source propagates to the flow guide assembly 1 or the volute 3, noise reduction is performed. The sound wave usually travels in the opposite direction when it touches the guide assembly 1 or the volute 3 , so most of the incident wave will interfere with the ...

Embodiment 3

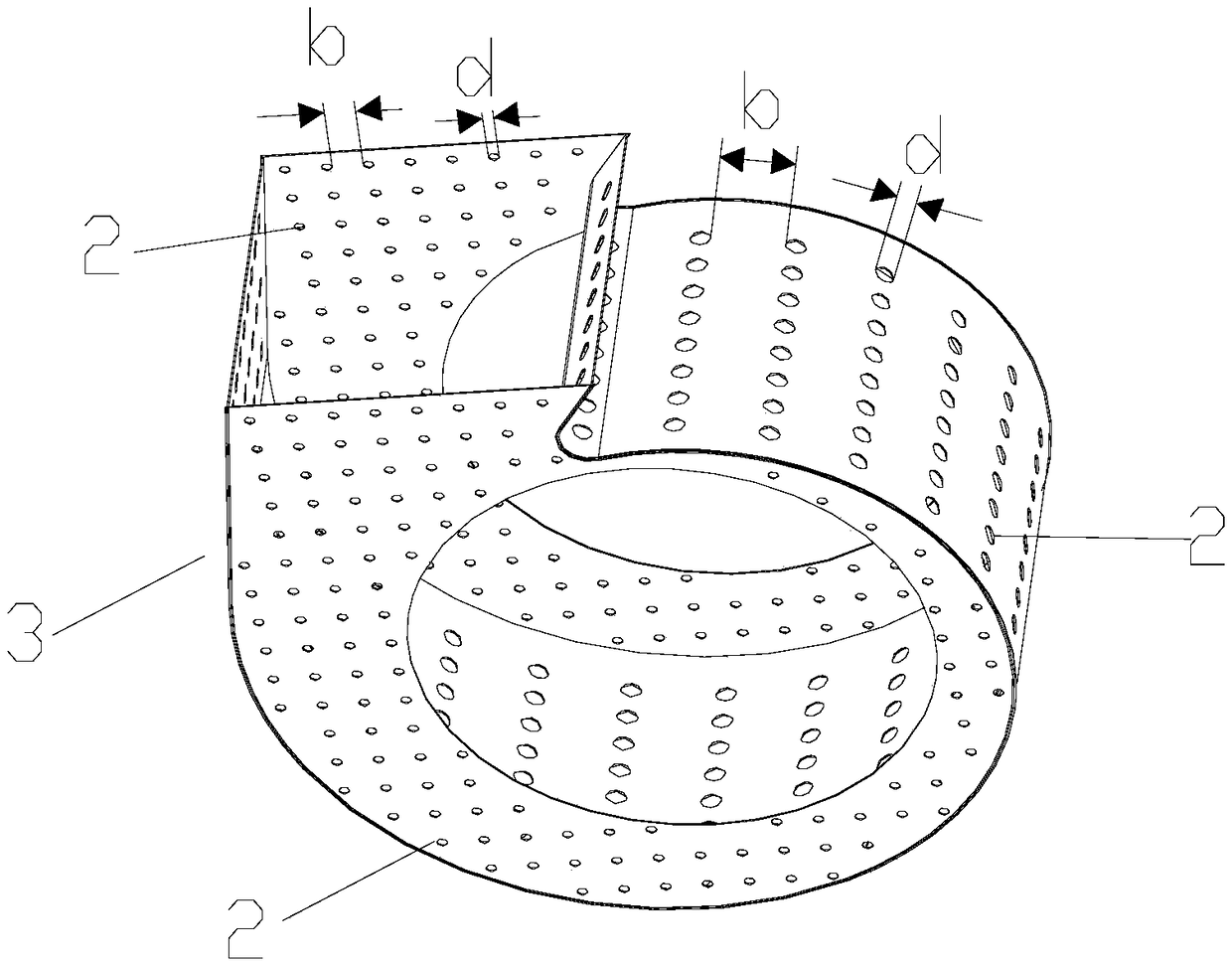

[0062] A range hood with a noise filtering function guide assembly, such as Figure 4 and 5 As shown, other features are the same as those in Embodiment 1, except that the flow guide assembly 1 of this embodiment is specifically a metal flow guide assembly 1 . The volute 3 is specifically a metal volute 3 .

[0063] The noise elimination frequency range of the volute 3 and the guide assembly 1 is 100Hz-8000Hz.

[0064] It should be noted that the flow guide assembly 1 of the present invention can also be a plastic flow guide assembly 1 or an alloy flow guide assembly 1 . The volute 3 can also be a plastic volute 3 or an alloy volute 3, and the specific implementation depends on the actual situation.

[0065] The thickness of the guide assembly 1 and the volute 3 of the present invention is less than 20mm, because too thick will increase the overall weight of the range hood.

[0066] Both the guide assembly 1 and the volute 3 in this embodiment are integrally connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com