Colorant for digital printing of polyester fabric and production technique thereof

A digital printing and polyester fabric technology, applied in the field of printing and polyester fabric dyeing, can solve the problems of slow dyeing speed, poor level dyeing, and poor dyeing depth, and achieve good rubbing fastness, clear printing outline, and stable color light Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

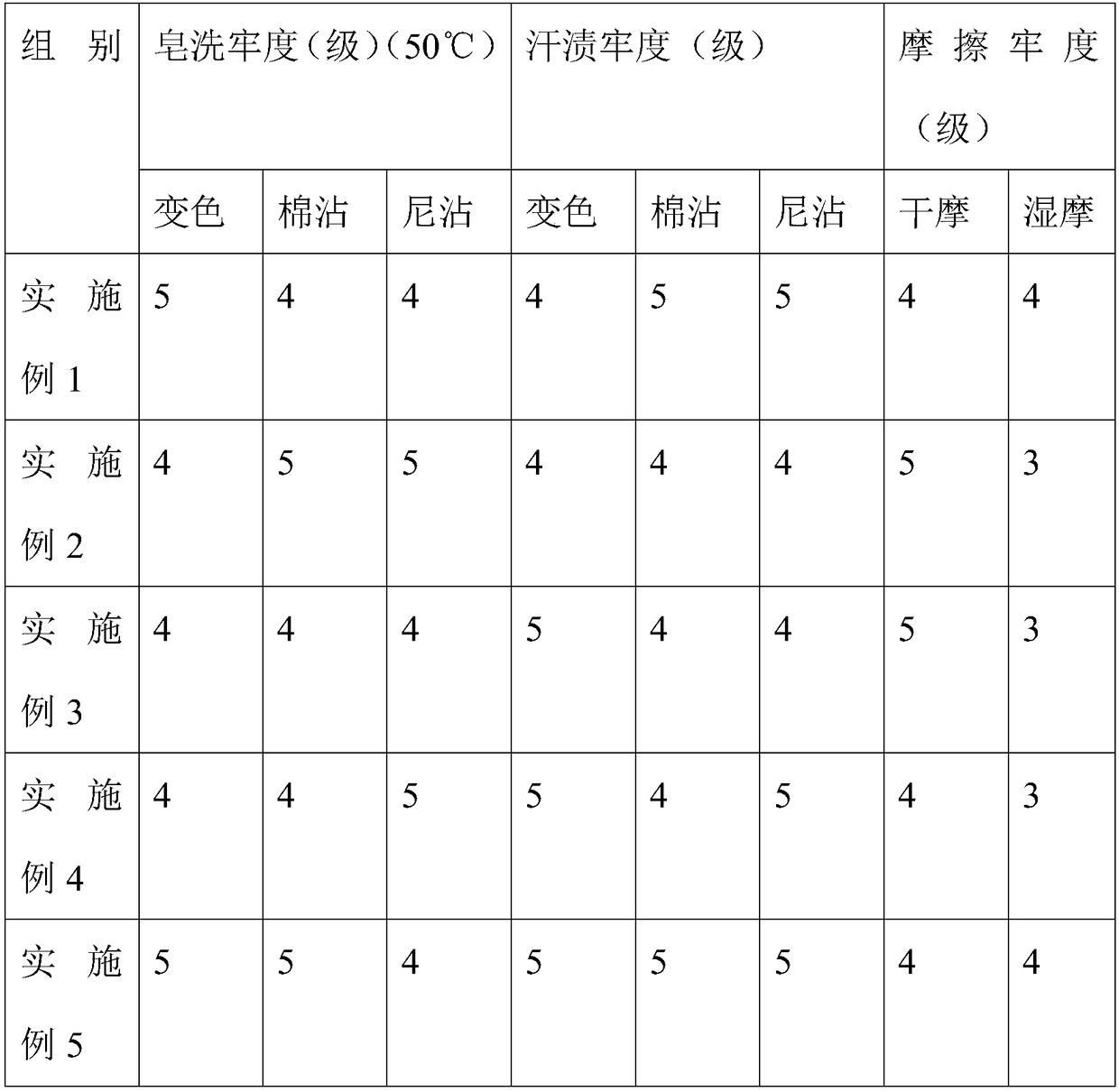

Examples

Embodiment 1

[0044] A coloring agent for digital printing of polyester fabrics, comprising the following components by mass fraction: Disperse Red 60#60%;

[0045] Disperse Rosé BG20%;

[0046] Diffusion agent NNO10%;

[0047] Leveling agent 6%;

[0048] Anti-wrinkle softener 3%;

[0049] Anti-migration agent 1%.

[0050] A kind of production technology for the colorant of polyester fabric digital printing, comprises the following steps:

[0051] The first step is to add 10 ℃ cold water to the dyeing vat;

[0052] The second step is to add the above-mentioned dosage of leveling agent, anti-migration agent and anti-wrinkle softener into the dye vat;

[0053] The third step, adjust the Ph value to 5.5 with glacial acetic acid;

[0054] The fourth step is to raise the temperature to 50°C, add the above-mentioned doses of Disperse Red 60#, Disperse Pink BG, and diffusing agent and maintain it for 8 minutes.

[0055] The fifth step is to continue to heat up to 85°C and maintain it for 20...

Embodiment 2

[0057] A coloring agent for digital printing of polyester fabrics, comprising the following components by mass fraction: Disperse Red 60#70%;

[0058] Disperse Rosé BG15%;

[0059] Diffusion agent NNO5%;

[0060] Leveling agent 5%;

[0061] Anti-wrinkle softener 4.5%;

[0062] Anti-migration agent 0.5%.

[0063] A kind of production technology for the colorant of polyester fabric digital printing, comprises the following steps:

[0064] The first step is to add 15 ℃ cold water to the dyeing vat;

[0065] The second step is to add the above-mentioned dosage of leveling agent, anti-migration agent and anti-wrinkle softener into the dye vat;

[0066] The third step, adjust the Ph value to 6 with glacial acetic acid;

[0067] The fourth step is to raise the temperature to 55°C, add the above-mentioned doses of Disperse Red 60#, Disperse Pink BG, and diffusing agent and maintain it for 10 minutes.

[0068] The fifth step, continue to heat up to 90°C and maintain it for 25 mi...

Embodiment 3

[0070] A coloring agent for digital printing of polyester fabrics, comprising the following components by mass fraction: Disperse Red 60#62%;

[0071] Disperse Rosé BG10%;

[0072] Diffusion agent NNO15%;

[0073] Leveling agent 6%;

[0074] Anti-wrinkle softener 5%;

[0075] Anti-migration agent 2%.

[0076] A kind of production technology for the colorant of polyester fabric digital printing, comprises the following steps:

[0077] The first step is to add 20 ℃ cold water to the dyeing vat;

[0078] The second step is to add the above-mentioned dosage of leveling agent, anti-migration agent and anti-wrinkle softener into the dye vat;

[0079] The third step, adjust the Ph value to 6.5 with glacial acetic acid;

[0080] The fourth step is to raise the temperature to 60°C, add the above-mentioned doses of Disperse Red 60#, Disperse Pink BG, and diffusing agent and maintain it for 15 minutes.

[0081] The fifth step, continue to heat up to 95°C and maintain it for 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com