Automatic ink removing device

An automatic and paper technology, applied in the post-processing of waste paper, printing, and post-processing of printing, etc., can solve the problems of short aging performance, shortened paper life cycle, and small inheritance, so as to increase the life cycle and achieve sustainable development. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

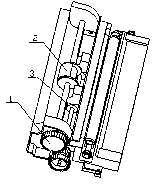

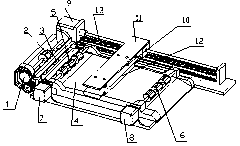

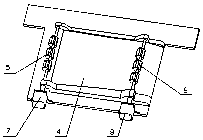

[0017] The automatic deinking device of the present invention includes a sorting wheel (2) driven by a gear (1) to divide the paper into single pages and transmit them to the fixed table (4) through the feeding wheel (3) and six front and rear The fixed wheels (5) (6) are driven and rotated by two motors (7) (8) respectively to compress and fix the paper. The motor (9) drives the erasing arm (12) vertically fixed on the horizontal arm (11) by four springs (10) to complete the erasing of the paper fixed on the fixed table (4) along the direction of the guide rail slide table (13) parallel movement. After wiping, the motor (7) (8) drives the front and rear six fixed wheels (5) (6) to lift up, and the paper is taken out through the horizontal movement of the erasing arm (12).

[0018] The paper feeding mechanism includes a paging mechanism, that is, the paging wheel (2) driven by the gear (1) rotates the paper into single pages and then enters the device through the feeding whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com