Mounting device for a print head

A technology for installing equipment and printing heads, which is applied in printing, printing devices, inking devices, etc., and can solve the problems that fine mechanical solutions are easily polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

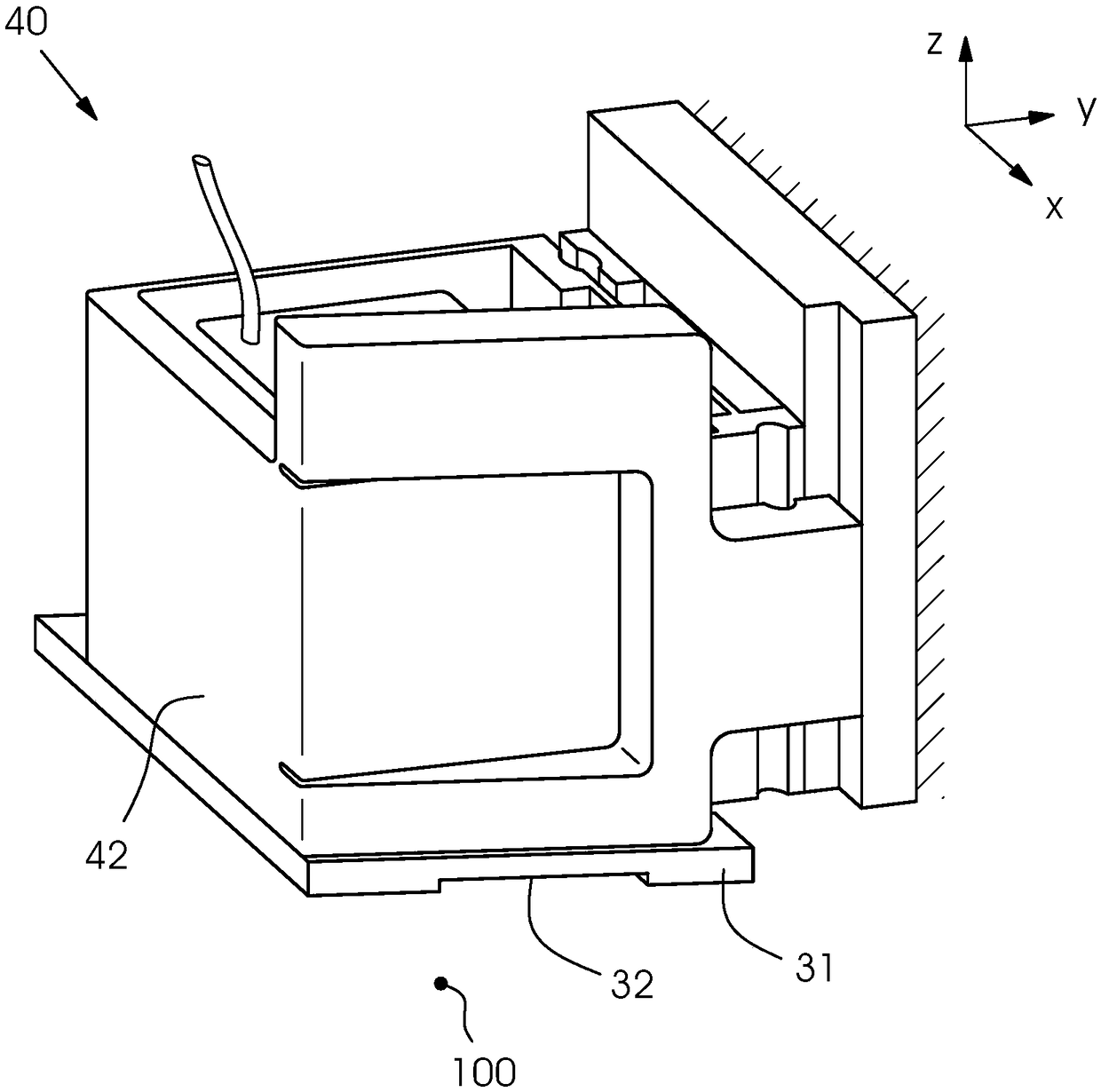

[0029] figure 1 The spatial view of is given an overview of the mounting device 40 and its structure. The mounting device 40 serves to receive the printing head 31 in a calibratable manner. For this purpose, the mounting device 40 has a frame 42 which can be fastened to a rigid carrier 41 . The rigid carrier 41 may be part of the frame of the digital printing machine 10 . The printing head 31 is received by the frame 42 in such a way that the area of the frame 42 surrounds the sides of the printing head 31 , ie the printing head 31 is arranged in the center of the frame 42 . The printing head 31 has a nozzle plate 32 on its lower end, which protrudes beyond the frame 42 of the mounting device 40, and wherein the nozzles of the nozzle plate 32 can discharge the smallest ink drops, It is used to print an image on a sheet 100 (not further shown) below the printing head 31 . The control lines and the ink supply of the printing head 31 are not further shown in the figures.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com