Laminar flow collecting pipe cooling water quantity control device

A cooling water volume and control device technology, applied in workpiece cooling devices, metal rolling, manufacturing tools, etc., can solve the problems of difficulty in regulating cooling water volume, high equipment manufacturing and operating costs, and improve maintainability and operating costs. Low, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

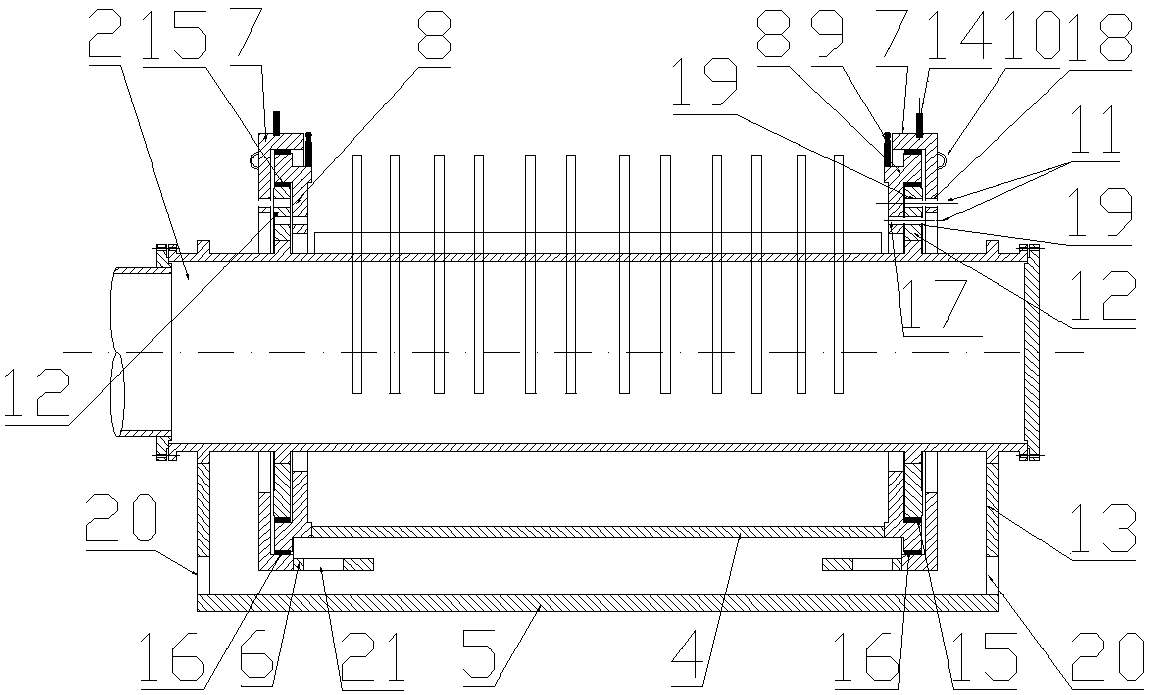

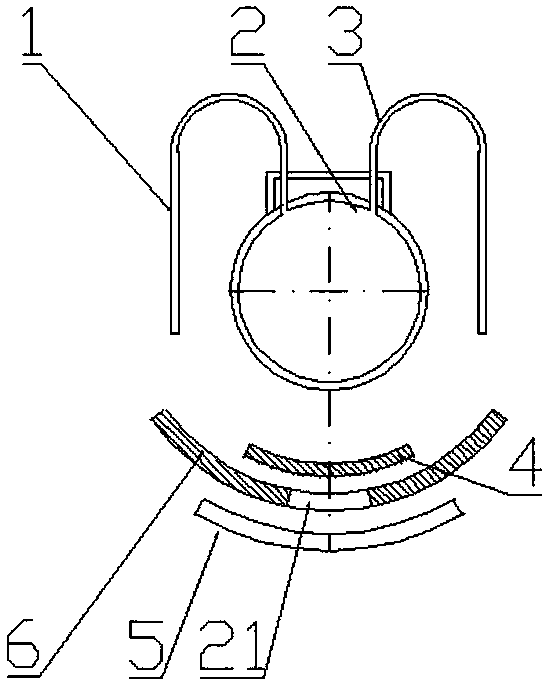

[0034] Embodiment 1, the device of the present invention is used to control the maximum cooling water volume when producing narrow plates, see figure 1 , figure 2 , the header 2 is fixed on the basis of the production line through a bracket, the front outlet pipe 1 and the rear outlet pipe 3 are two rows of headers, which are welded on both sides of the header 2, and the total of the front outlet pipe 1 and the rear outlet pipe 3 The water output is the maximum water output of the rolling line, the water output of the front water outlet pipe 1 is the minimum water output of the rolling line, and the water output of the rear water outlet pipe 3 is between the two. The mounting plate 12 and the header 2 are connected by threads. The inner copper sliding bearing 15 is arranged on the mounting plate 12, so that the flow drive plate 8 can rotate flexibly, and two circles of fixed through holes 19 are arranged on the mounting plate 12, 5 each, so that the fixed pins of the flow dri...

Embodiment 2

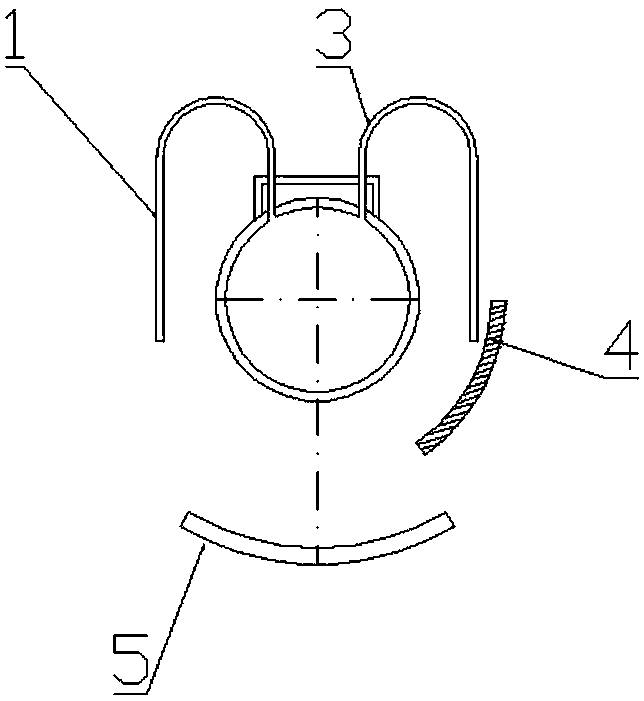

[0035] Embodiment 2, the minimum cooling water regulation when the device of the present invention is used to produce narrow plates, see figure 1 , figure 2 , image 3 , adjust the device in Example 1, rotate the flow drive plate 8 through the flow handle 9, make the non-porous arc plate 4 block the rear outlet pipe 3, and align the flow positioning hole 17 with the fixed through hole 19 on the installation plate 12 , Insert the fixed pin 11, the outlet water of the rear outlet pipe 3 is collected by the chute 5, and flows out through the guide hole 20.

Embodiment 3

[0036] Embodiment 3, when the device of the present invention is used for medium cooling water regulation when producing narrow plates, see figure 1 , figure 2 , Figure 4 , adjust the device in Example 1, through the flow handle 9, rotate the flow drive plate 8 to block the front outlet pipe 1, and align the flow positioning hole 17 with the fixing through hole 19 on the mounting plate 12, insert the fixing pin 11, The outlet water of the front outlet pipe 1 is collected by the chute 5 and flows out through the diversion hole 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com