Probiotic fermented soya beans and making method thereof

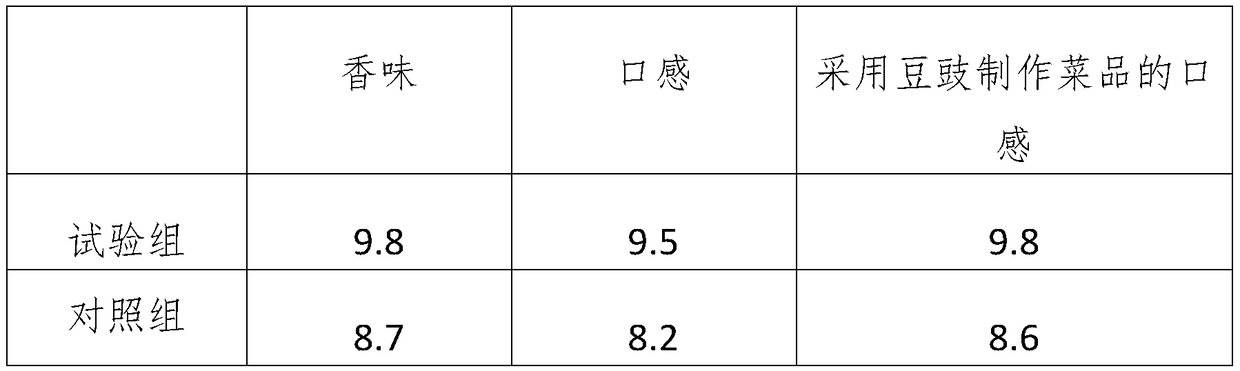

A technology of probiotics and fermented soybeans, which is applied in the field of fermented food, can solve the problems of no fragrance and general taste, and achieve the effects of fragrant taste, shortened fermentation cycle and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Probiotic fermented soya bean of the present invention, preparation method is as follows:

[0027] (1) produce strain activator, glutinous rice flour 8kg, green apple juice 6kg, fresh capsicum 8kg, leek 1kg, garlic 1kg, cowpea 0.3kg, ginger 0.1kg, wild garlic 0.8kg, grapefruit 1kg, blueberry 0.6kg are processed into Add 29kg of pure water to the powder with a particle size of 0.08cm, heat to 90°C, soak in heat for 40min, concentrate under reduced pressure to a water content of 70%, and obtain a culture medium. After the temperature is lowered to room temperature, inoculate 5% of the medium mass Lactic acid bacteria, wherein the lactic acid bacteria are composed of Lactobacillus helveticus, Lactobacillus delbrueckii, and Lactobacillus acidophilus with a mass ratio of 1:1:1, fermented at 35°C for 3 days;

[0028] (2) To prepare the fermented product, heat 16kg of soybeans to 70°C by microwave, keep warm for 20s, mix with 5kg of chickpeas, 7kg of barley, 1kg of lotus root,...

Embodiment 2

[0031] Probiotic fermented soya bean of the present invention, preparation method is as follows:

[0032] (1) To prepare the strain activator, 12 kg of glutinous rice flour, 8 kg of green apple juice, 12 kg of fresh pepper, 2.5 kg of leek, 2.5 kg of garlic, 0.5 kg of cowpea, 0.3 kg of ginger, 1.2 kg of wild garlic, 1.5 kg of grapefruit, and 0.8 kg of blueberry kg is processed into a powder with a particle size of 0.2 cm, added with 45 kg of pure water, heated to 90°C, soaked for 40 minutes under heat preservation, concentrated under reduced pressure to a water content of 60%, to obtain a culture medium, and when the temperature is lowered to room temperature, inoculate 3 % of lactic acid bacteria, wherein the lactic acid bacteria are composed of Lactobacillus helveticus, Lactobacillus delbrueckii and Lactobacillus acidophilus with a mass ratio of 1:1:1, fermented at 42°C for 5 days;

[0033] (2) To prepare the fermented product, heat 18kg of soybeans to 80°C by microwave, keep...

Embodiment 3

[0036] Probiotic fermented soya bean of the present invention, preparation method is as follows:

[0037] (1) produce strain activator, glutinous rice flour 9kg, green apple juice 7kg, fresh capsicum 9kg, leek 2kg, garlic 2kg, cowpea 0.2kg, ginger 0.2kg, wild garlic 1kg, pomelo 0.3kg, blueberry 0.7kg are processed into Add 50kg of pure water to the powder with a particle size of 0.09cm, heat it to 90°C, soak it for 35 minutes, concentrate it under reduced pressure to a water content of 65%, and obtain a culture medium. Lactic acid bacteria, wherein the lactic acid bacteria are composed of Lactobacillus helveticus, Lactobacillus delbrueckii, and Lactobacillus acidophilus with a mass ratio of 1:1:1, fermented at 42°C for 5 days;

[0038] (2) To prepare the fermented product, heat 17kg of soybeans to 75°C by microwave, keep warm for 25s, mix with 6kg of chickpeas, 8kg of barley, 1.5kg of lotus root, 1.5kg of bamboo shoots, 0.8kg of white radish, 0.8kg of papaya, taro 1.5kg, 1.3k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com