High-voltage circuit breaker system with applicable plateau environment performance

A high-voltage circuit breaker and high-altitude environment technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve problems such as safety accidents, changes in the length of insulating rods, occurrences, etc., to achieve increased insulation performance and strong self-cleaning Pollution ability, increase the effect of creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

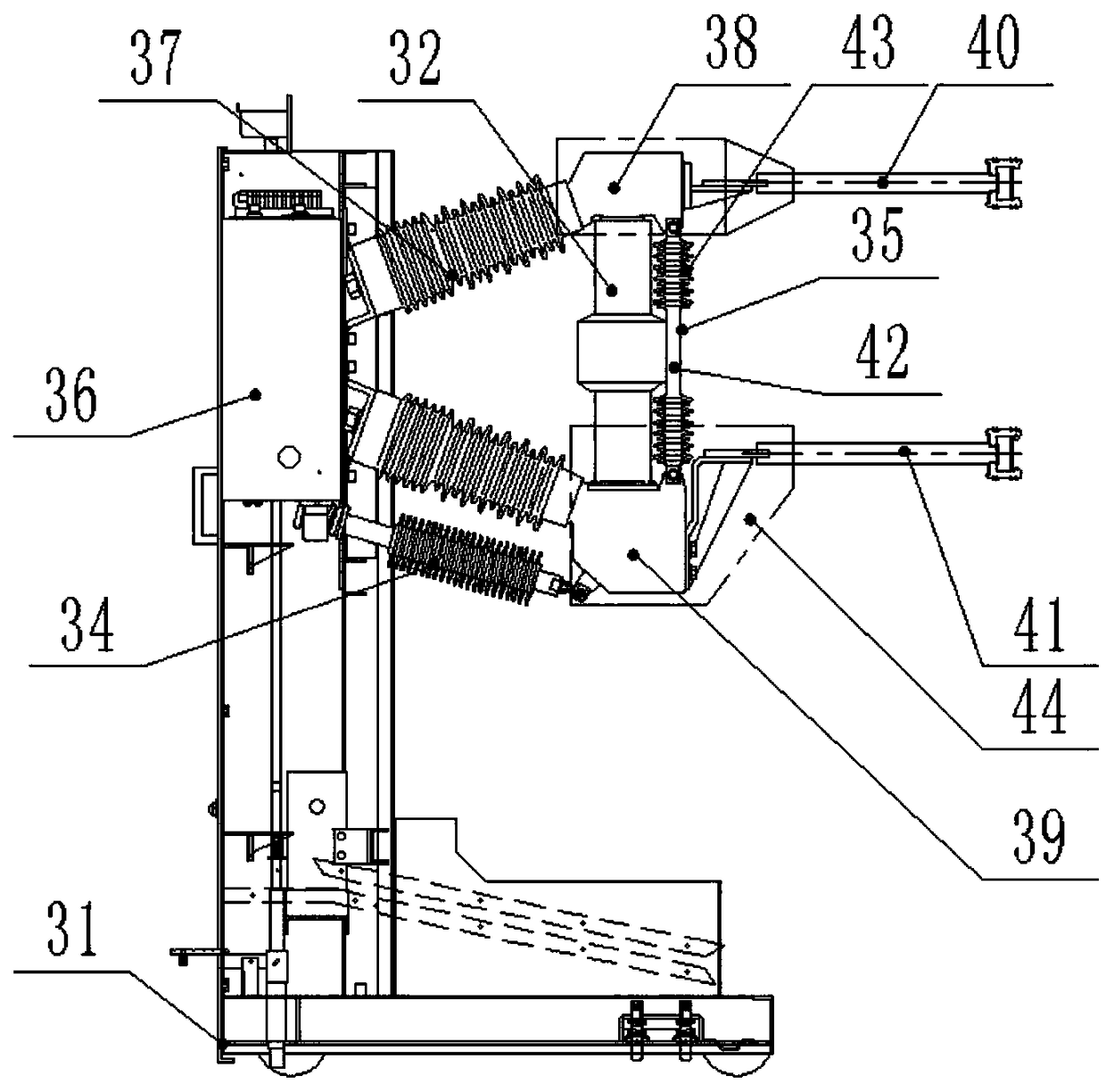

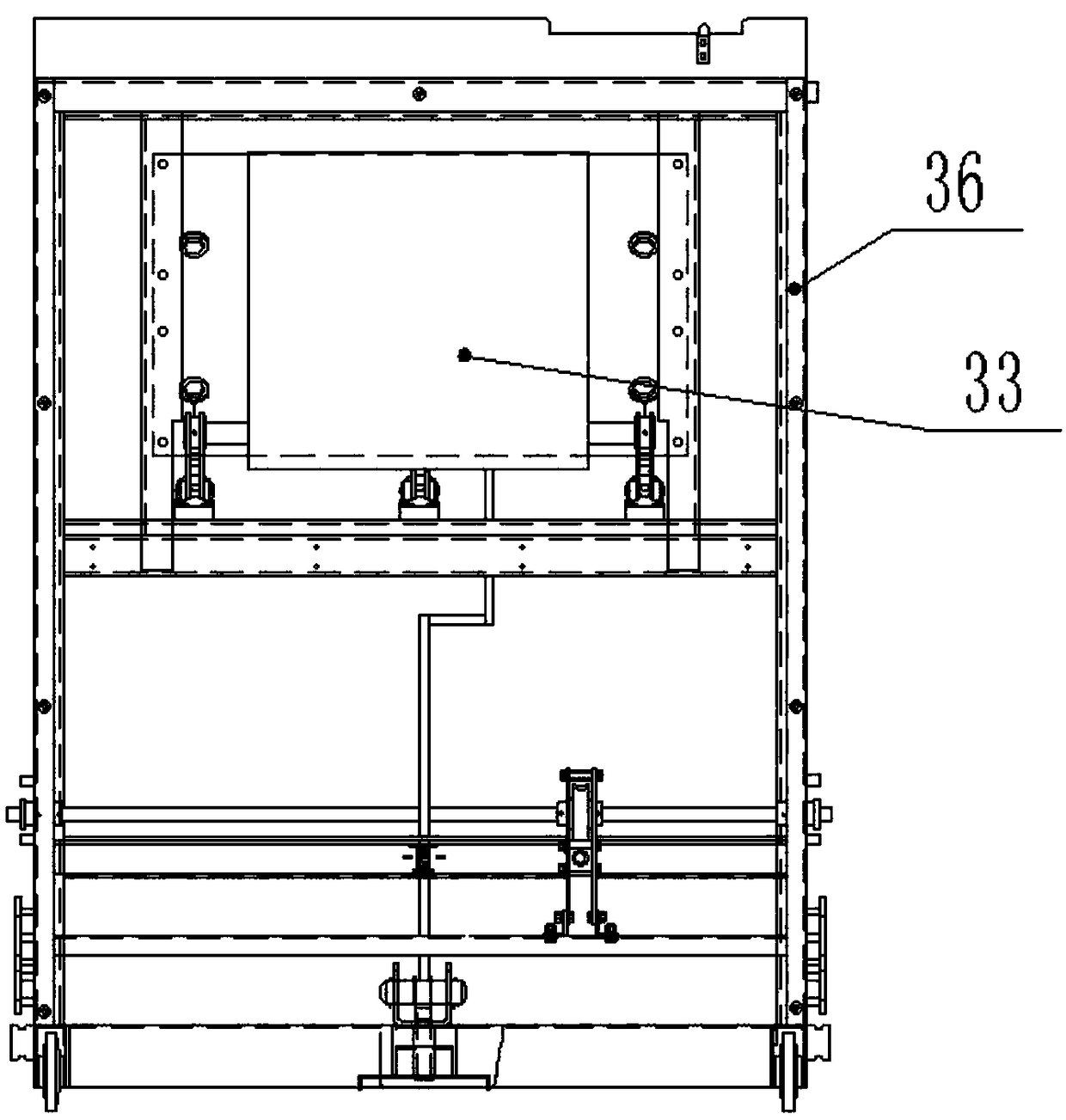

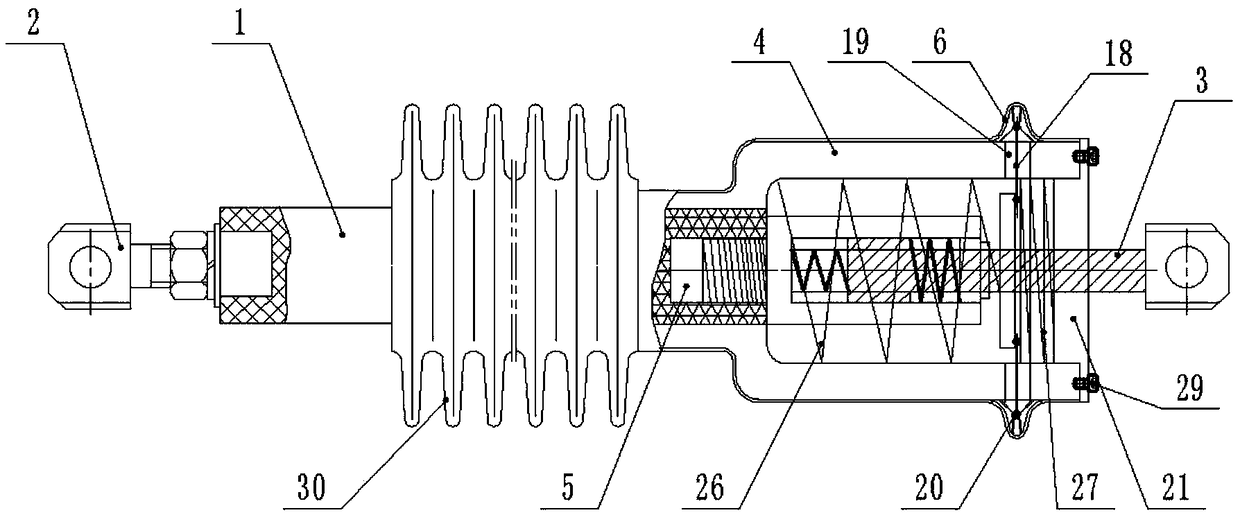

[0055] Such as Figure 1-7 As shown, the present invention is a high-voltage circuit breaker system with performance applicable to plateau environments, including a vehicle frame 31, a vacuum interrupter 32, an operating mechanism 33, connecting insulating pull rods 34 and insulating struts 35, and on the vehicle frame 31 The upper and lower layers of insulators 37 are fixed on the vertical frame 36, and the vehicle frame 31 includes the vertical frame 36 and the chassis vehicle. Position, exit refers to exit from the working position to the test position), the chassis car is used to carry the vacuum circuit breaker, and the driving wheels installed on the chassis car move forward or backward on the track in the switch cabinet. The upper end of the vacuum interrupter 32 is connected to the insulator 37 on the upper layer through the upper outlet seat 38, and the lower end of the vacuum interrupter 32 is connected to the insulator 37 on the lower layer through the lower outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com