Dark field defect detection device for large-caliber ultra-precise surface and measurement method thereof

A defect detection, ultra-precise technology, applied in measurement devices, scattering characteristics measurement, optical testing flaws/defects, etc., can solve the problems of low efficiency of dark field imaging method, inability to automatically measure the overall surface, etc., to achieve simple structure and remarkable effect , The effect of wide adaptability of material types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

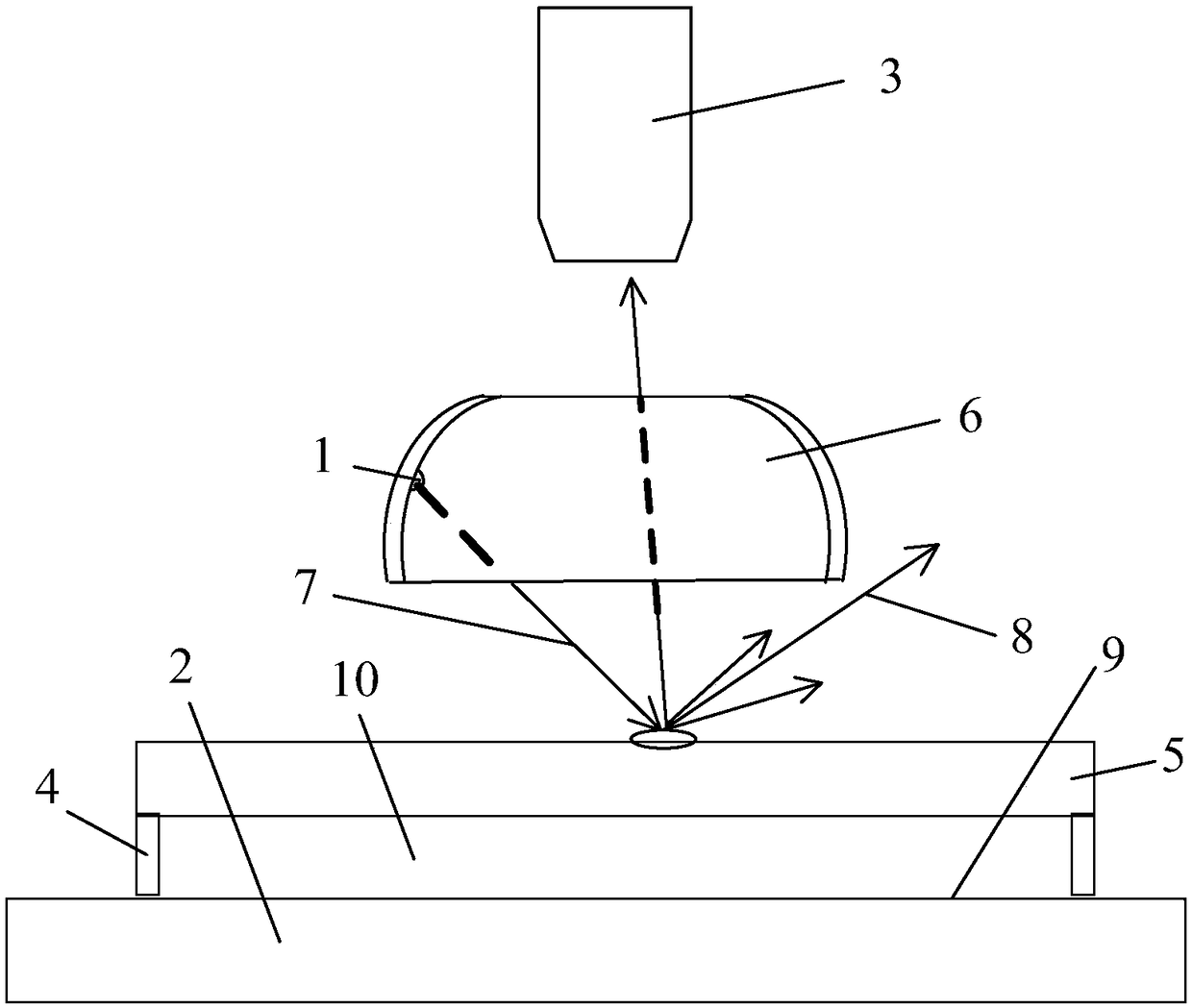

[0031] A dark-field defect detection device for large-diameter ultra-precision surfaces, such as figure 1 As shown, it is used to detect the sample to be tested of opaque material, and the sample to be tested is a large-caliber ultra-precision surface.

[0032] The detection device of the present invention includes: a light source 1, a sample holder for placing a sample to be tested 5, an imaging microscope 3 and a dome cover 6, such as figure 1 shown.

[0033] In the present invention, the light source 1 is arranged in the dome cover 6 , the sample to be tested 5 is fixed on the sample holder, the imaging microscope 3 is located above the sample to be tested 5 , and the dome cover 6 is located between the sample to be tested 5 and the imaging microscope 3 .

[0034] When in use, turn on the light source 1, adjust the height of the light source 1 so that the illumination light 7 emitted by the light source 1 obliquely irradiates the sample 5 to be tested, and the main reflect...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that this embodiment further optimizes the setting of the structure of each part, which can effectively improve the detection effect. The specific settings are as follows:

[0039] First, the setting of the light source 1 is optimized. In the present invention, the illumination light 7 emitted by the light source 1 is preferably white or blue. Secondly, the setting between the imaging microscope 3 and the dome cover 6 is optimized, that is, the aperture size of the imaging microscope 3 is smaller than the aperture size of the top opening of the dome cover 6 .

[0040] Example 2

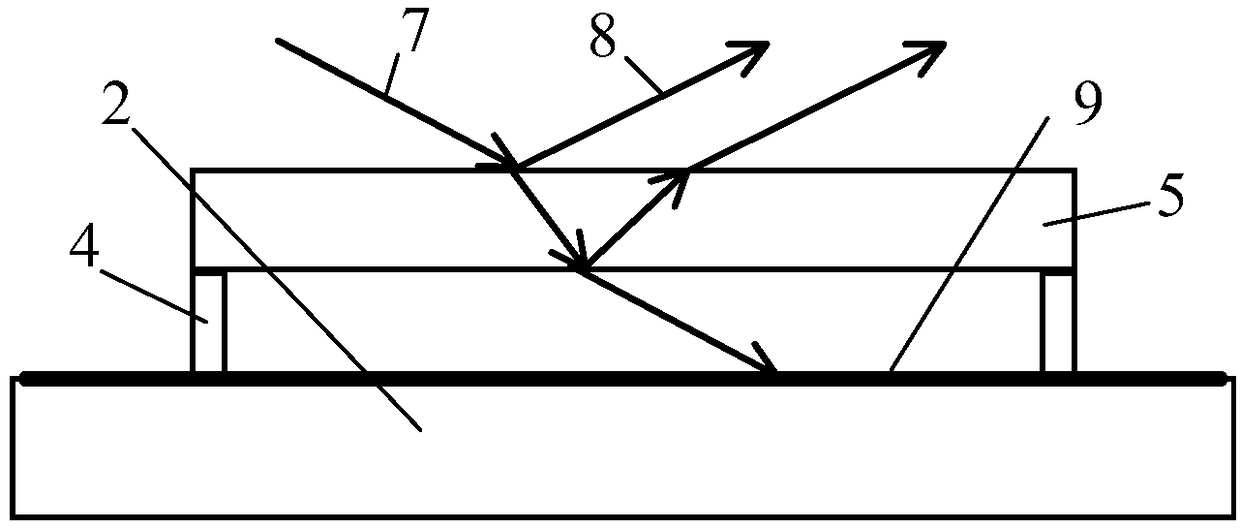

[0041] The difference between this embodiment and Embodiment 1 is that the structure of the sample holder is optimized in this embodiment, which is effectively suitable for testing samples of transparent materials, that is, it is suitable for large-caliber ultra-precision components with transparent surfaces, and the specific settings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com