Detection auxiliary device for wheel hub

An auxiliary device and wheel hub technology, which is applied in the field of wheel hub processing, can solve the problems of uncompact devices, low dispersion and integration, and large space occupation, achieving high integration, ensuring smooth operation, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

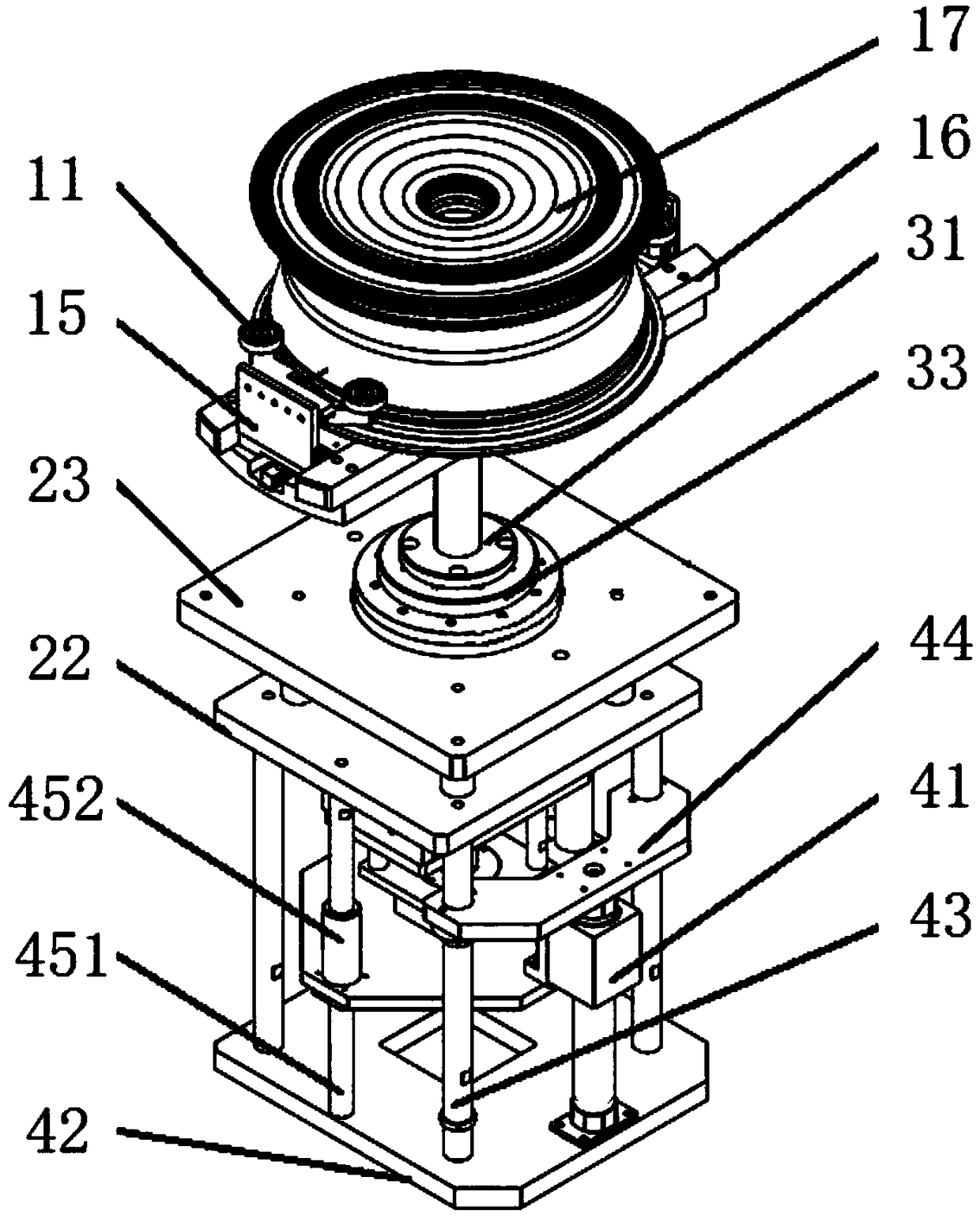

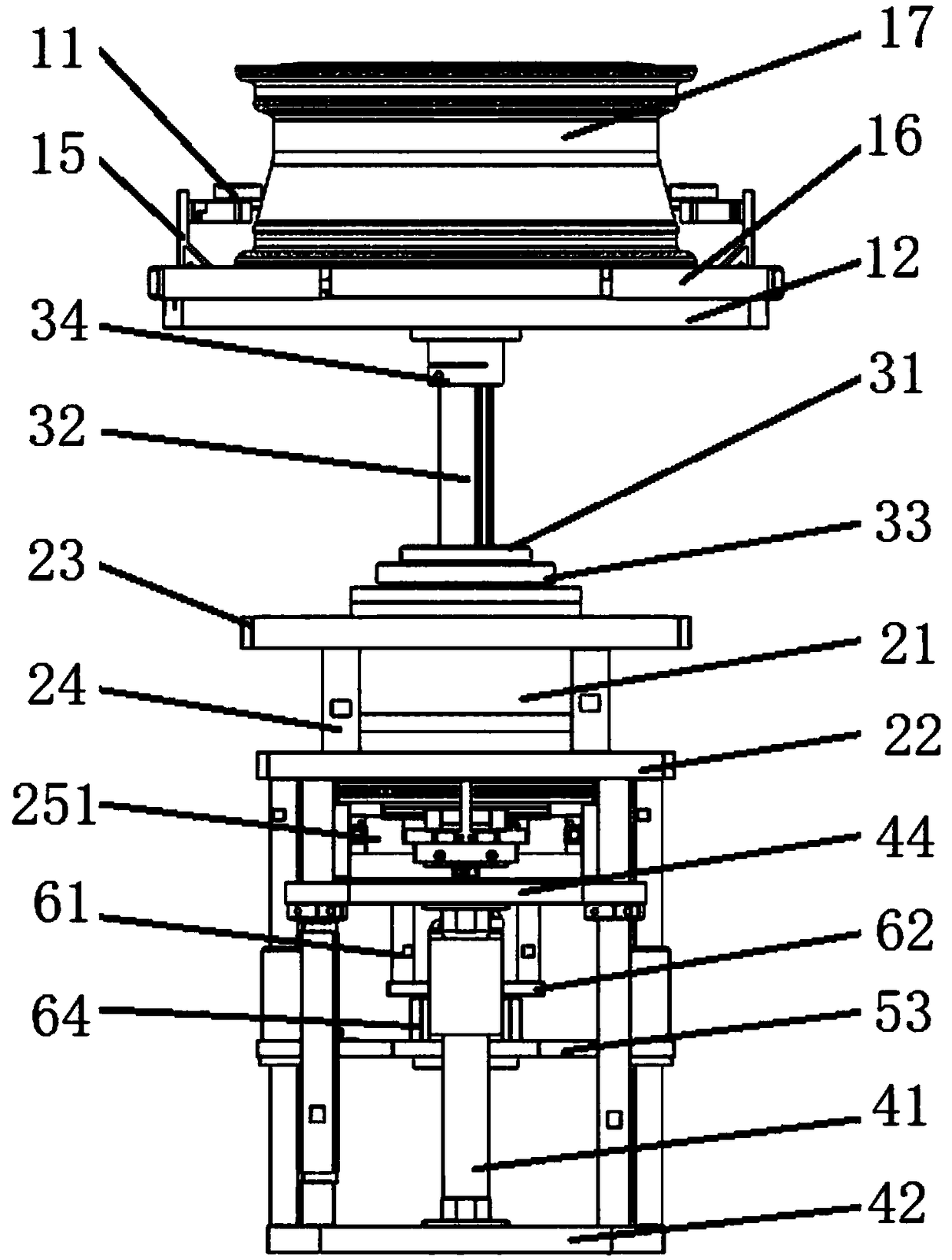

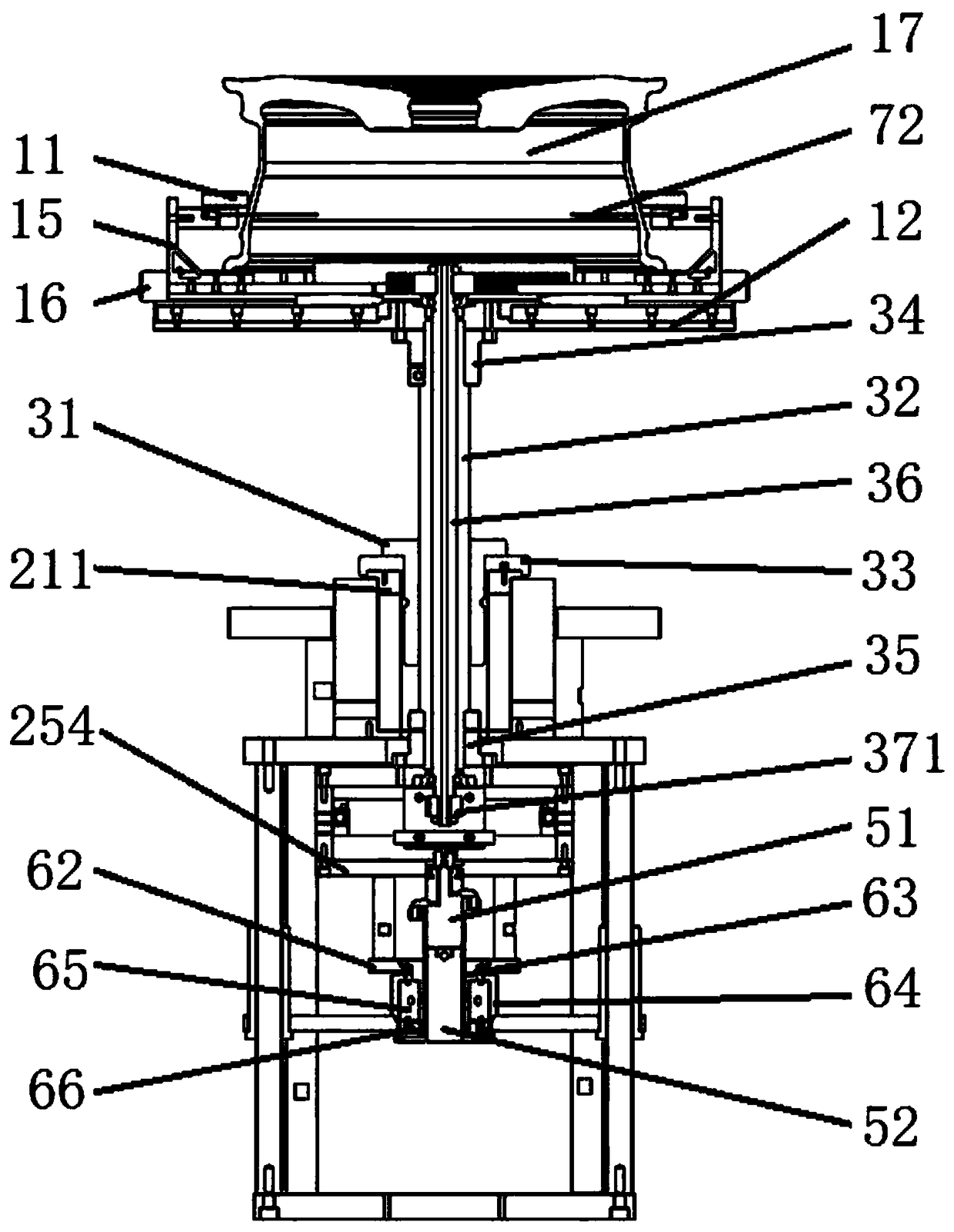

[0056] This embodiment provides a wheel hub detection auxiliary device, which includes: a fixing mechanism, a transmission mechanism, a driving mechanism, a jacking mechanism, an electrical separation mechanism, a position detection unit, and an installation base.

[0057] Among them, the fixing mechanism of the present invention mainly includes a clamping unit for fixing the hub 17; the driving mechanism includes a rotating unit 21 for driving rotation and a clamping drive unit, wherein the rotation unit 21 drives the fixing mechanism to rotate around the center of the hub 17, and the clamping drive The unit drives the clamping unit to move; the transmission mechanism is used to connect the rotation unit 21 and the fixing mechanism, and transmit the torque of the rotation unit 21 to the fixing mechanism; and the transmission mechanism is also connected to the clamping drive unit and the clamping unit, and is driven by the clamping The unit drive causes the clamping unit to clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com