Device and method for measuring multi-longitudinal mode laser resonant cavity FSR by large-amplitude laser self-mixing vibration signals

A vibration signal and laser technology, applied in the field of lasers, can solve the problems of unsuitable monitoring FSR universal measurement method, high price, low measurement accuracy, etc., achieve non-contact real-time high-precision measurement, convenient adjustment of optical path, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

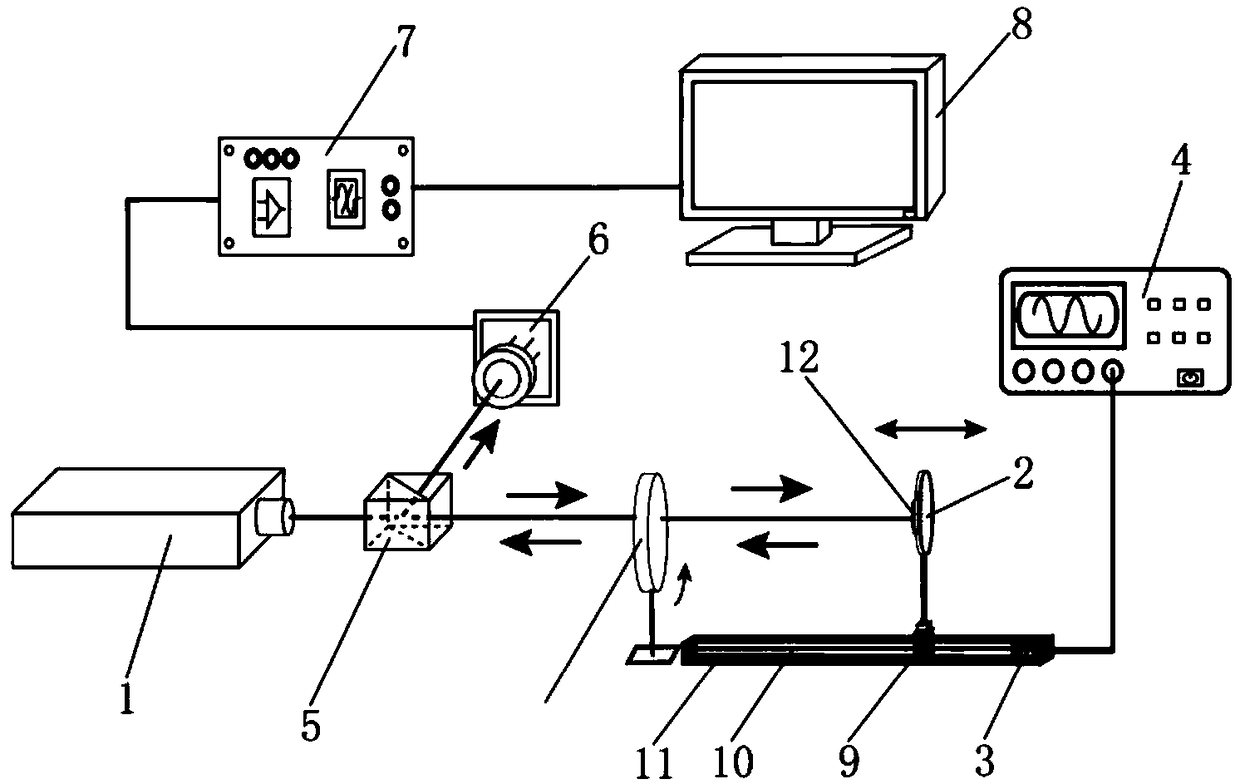

[0059] combine Figure 1 to Figure 5 , a specific embodiment of the present invention is described in detail, but the claims of the present invention are not limited in any way.

[0060] Self-mixing interferometry is a precision measurement technology, which is used for highly sensitive and precise non-contact measurement due to its simple structure, compactness and easy alignment. This technology has been widely researched and applied, mainly in the sensing and measurement of physical quantities related to object motion (such as vibration, displacement, velocity and stress, etc.) and laser-related parameters (such as: line width broadening factor α and feedback level factor C) Measurement etc.

[0061] A laser generally consists of an optical resonator, a gain medium, and an excitation source. Among them, the free spectral region of the laser resonator is defined in the same way as the free spectral region of the FP cavity etalon, and FSR is generally represented by Δν. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com