A high-efficiency propeller curing furnace

A propeller, high-efficiency technology, applied in household appliances, other household appliances, household components, etc., can solve problems such as large temperature difference, temperature difference, and affecting the quality of composite propellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

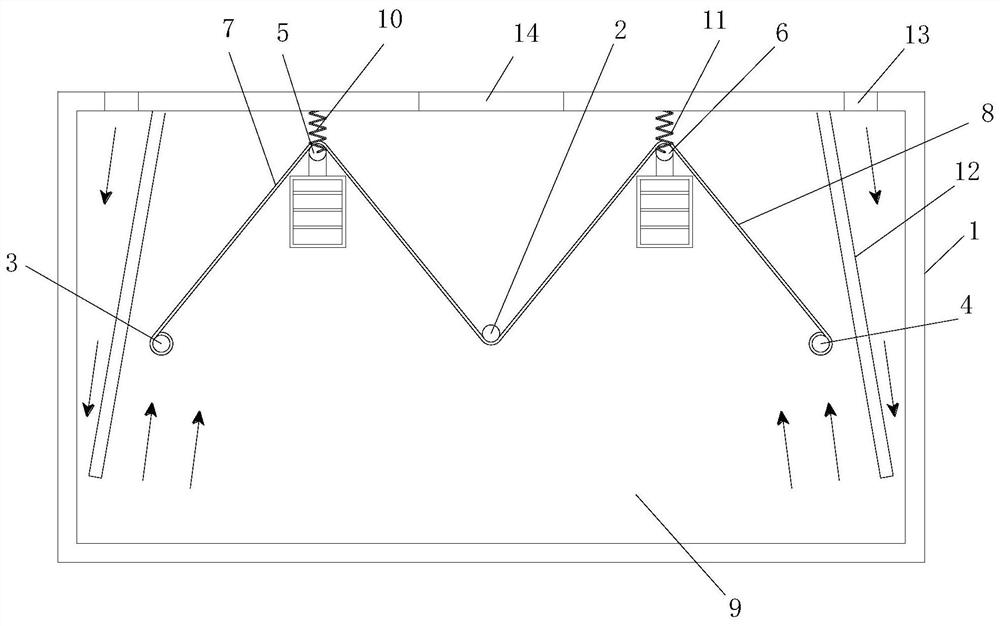

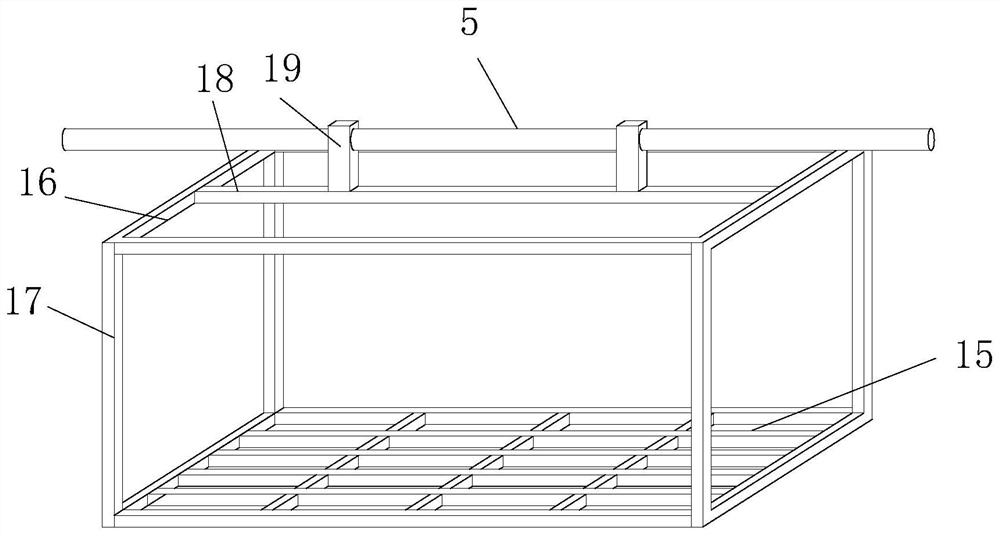

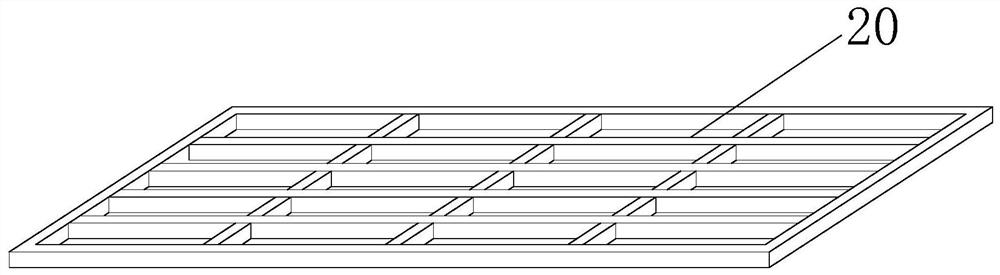

[0023] like Figure 1-Figure 5 as shown, figure 1 It is a structural schematic diagram of a high-efficiency propeller curing furnace proposed by the present invention; figure 2 It is a structural schematic diagram of the first mold frame in a high-efficiency propeller curing furnace proposed by the present invention; image 3 It is a structural schematic diagram of the second grid plate in the high-efficiency propeller curing furnace proposed by the present invention; Figure 4 It is a structural schematic diagram of the second mold frame in the high-efficiency propeller curing furnace proposed by the present invention; Figure 5 It is a structural schematic diagram of the fourth grid plate in the high-efficiency propeller curing furnace proposed by the present invention.

[0024] refer to Figure 1-Figure 5 , a high-efficiency propeller curing furnace proposed by the present invention includes a furnace body 1, a fixed shaft 2, a first material roll 3, a second material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com