Spherical lens polishing device

A lens polishing and lens technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, grinding automatic control device, etc., can solve the problem of not being able to check whether the polishing is qualified online, and achieve the effect of improving the efficiency of polishing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

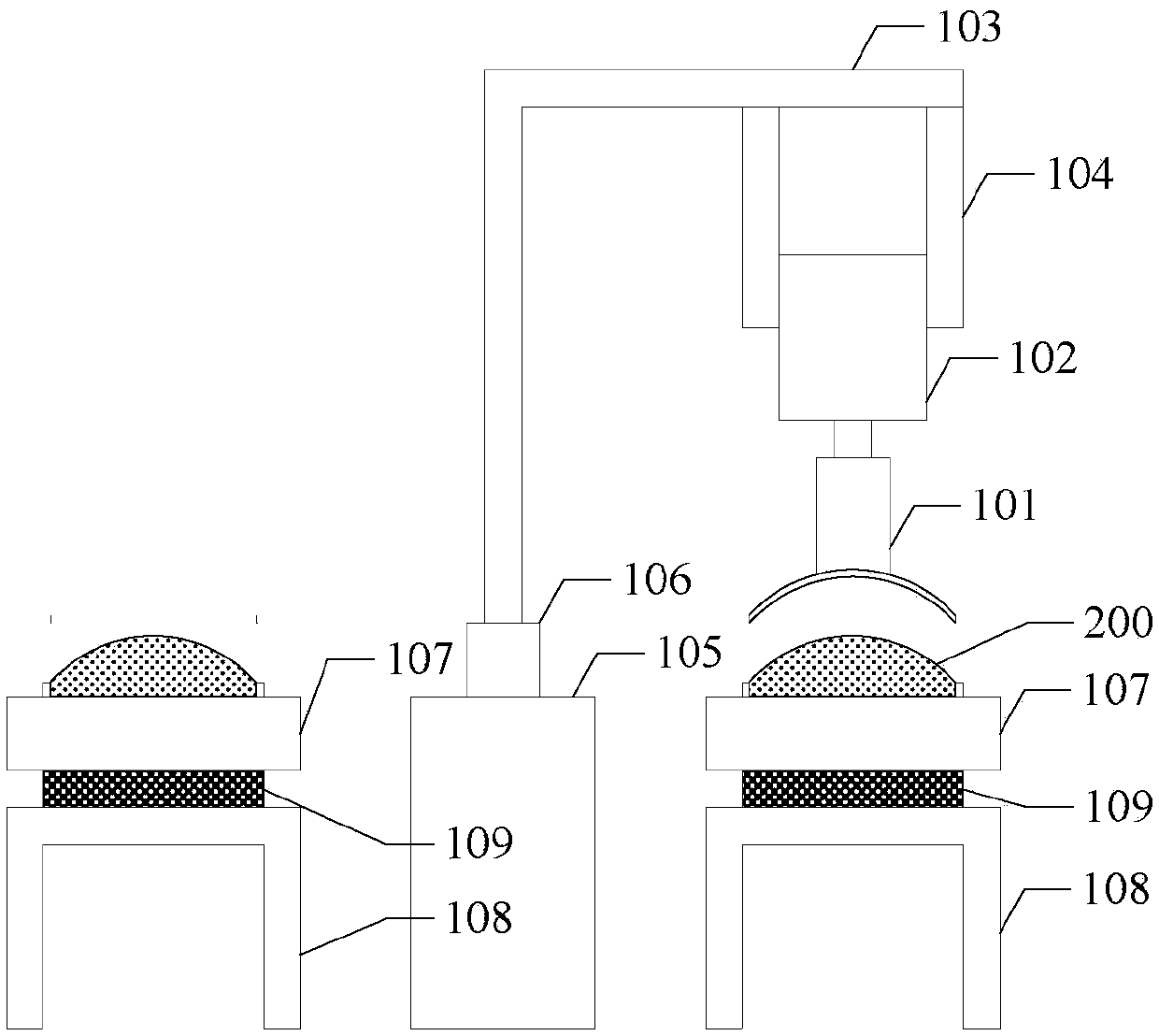

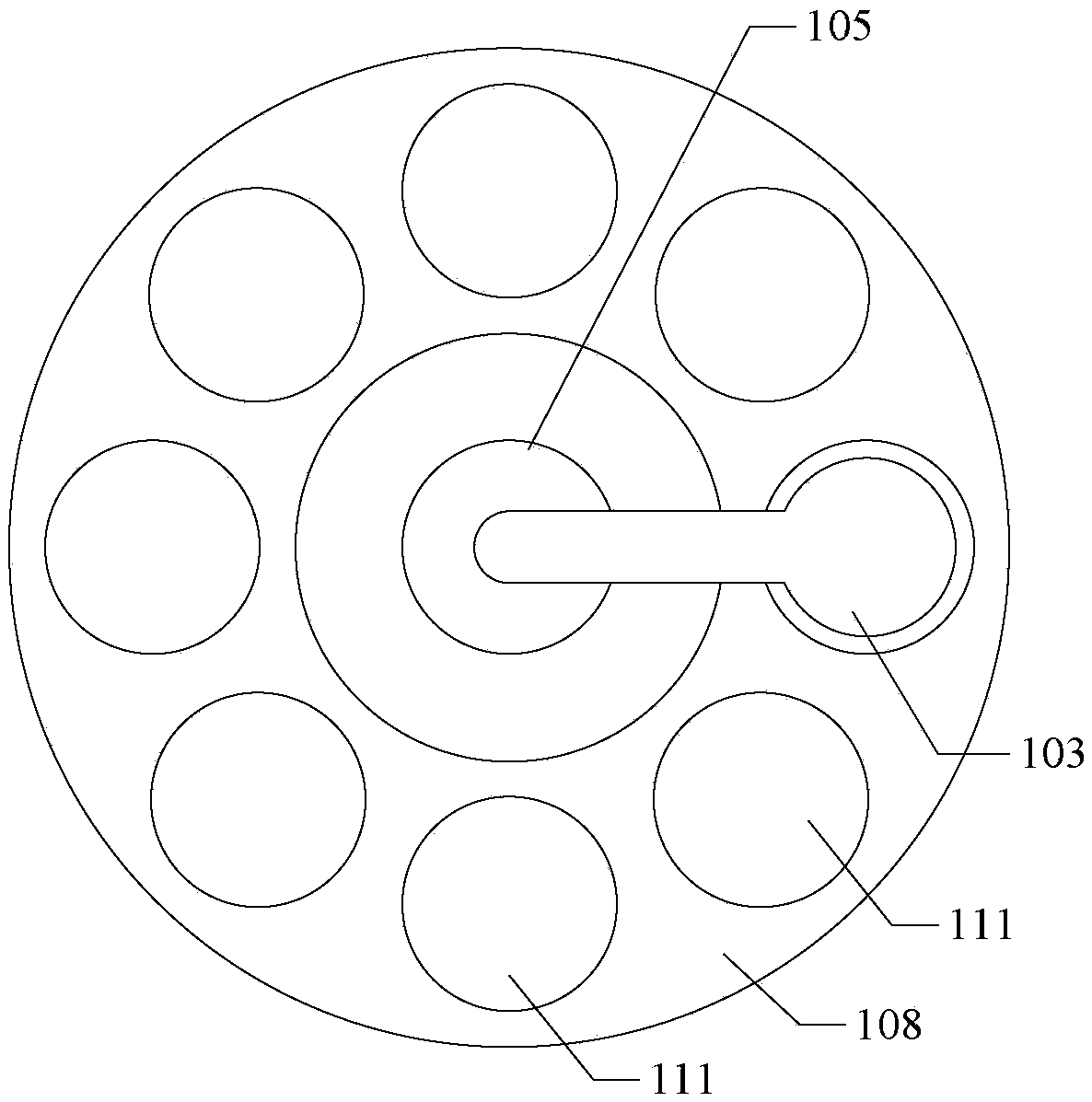

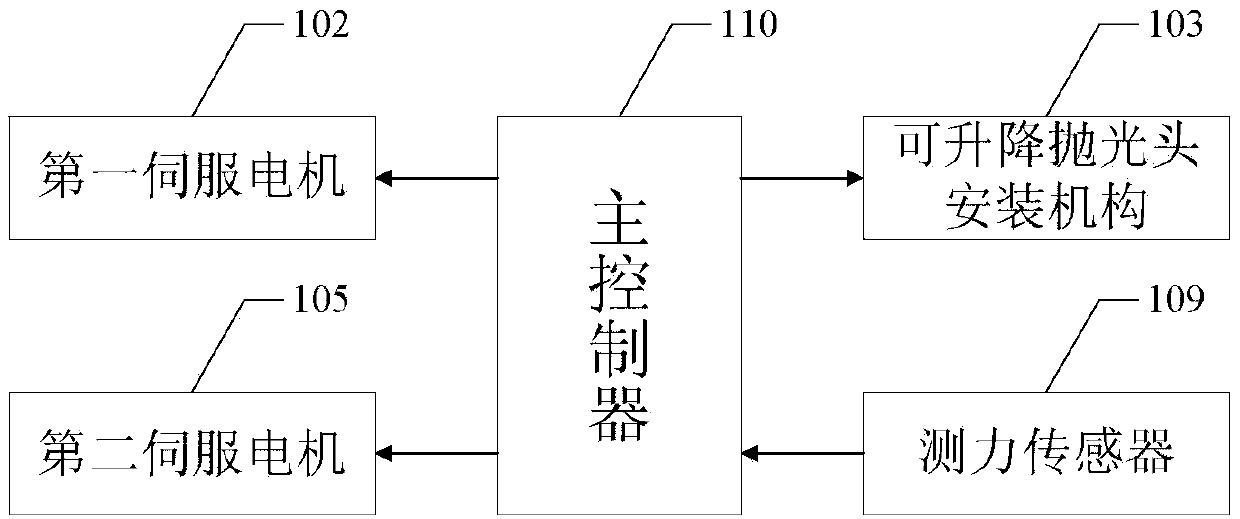

[0039] Such as Figure 1-4 As shown, in the first embodiment of the present invention, a spherical lens 200 polishing device is provided, and the device includes:

[0040] The polishing head 101 for polishing the spherical lens 200, the first servo motor 102 for driving the rotation of the polishing head 101, the liftable polishing head mounting mechanism 103 for adjusting the vertical height of the polishing head 101, Rotate and move the polishing head 101 to adjust the second servo motor 105 of the polishing station 111, the lens mounting table 107, the lens table base 108, the load cell 109 arranged between the lens mounting table 107 and the lens table base 108, and main controller 110;

[0041]The polishing head 101 is connected with the first drive shaft of the first servo motor 102, and the first servo motor 102 is installed on the motor mounting par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com