Automatic production device for carrying out rust-proof treatment on end part of steel pipe

A technology of anti-rust treatment and automatic production, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low production efficiency, achieve the effects of avoiding pollution, improving coating uniformity, and improving spraying uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

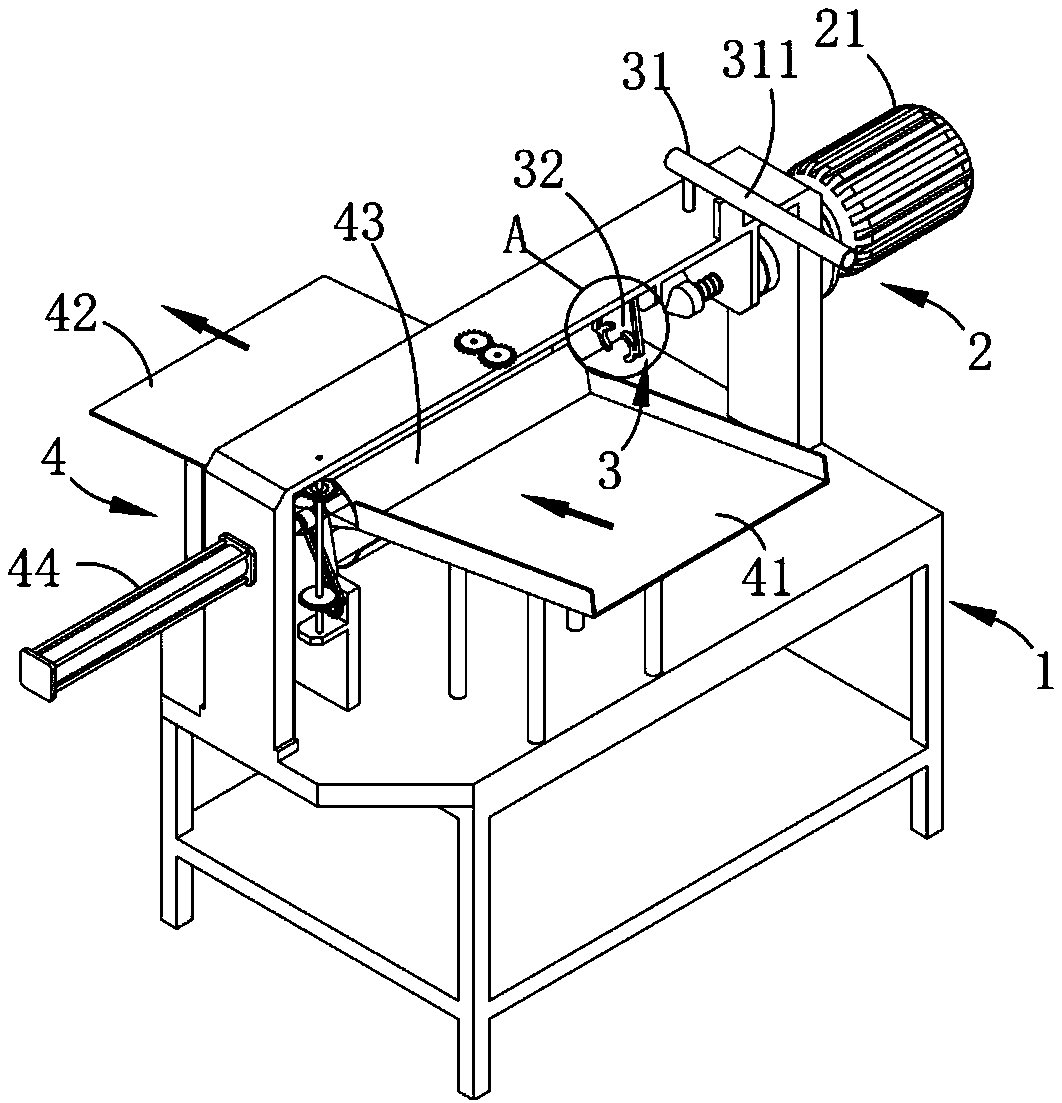

[0039] Such as figure 1 , 2 Shown in and 3, a kind of automatic production device that is used for the antirust treatment of steel pipe end, comprises frame 1, also includes being arranged on this frame 1:

[0040] positioning mechanism 2;

[0041] Oiling mechanism 3, described oiling mechanism 3 comprises the oil spray assembly 31 that is arranged on the one end of described positioning mechanism 2 and is positioned at this end of this oil spray assembly 31 and is away from the coating assembly 32 of described positioning mech...

Embodiment 2

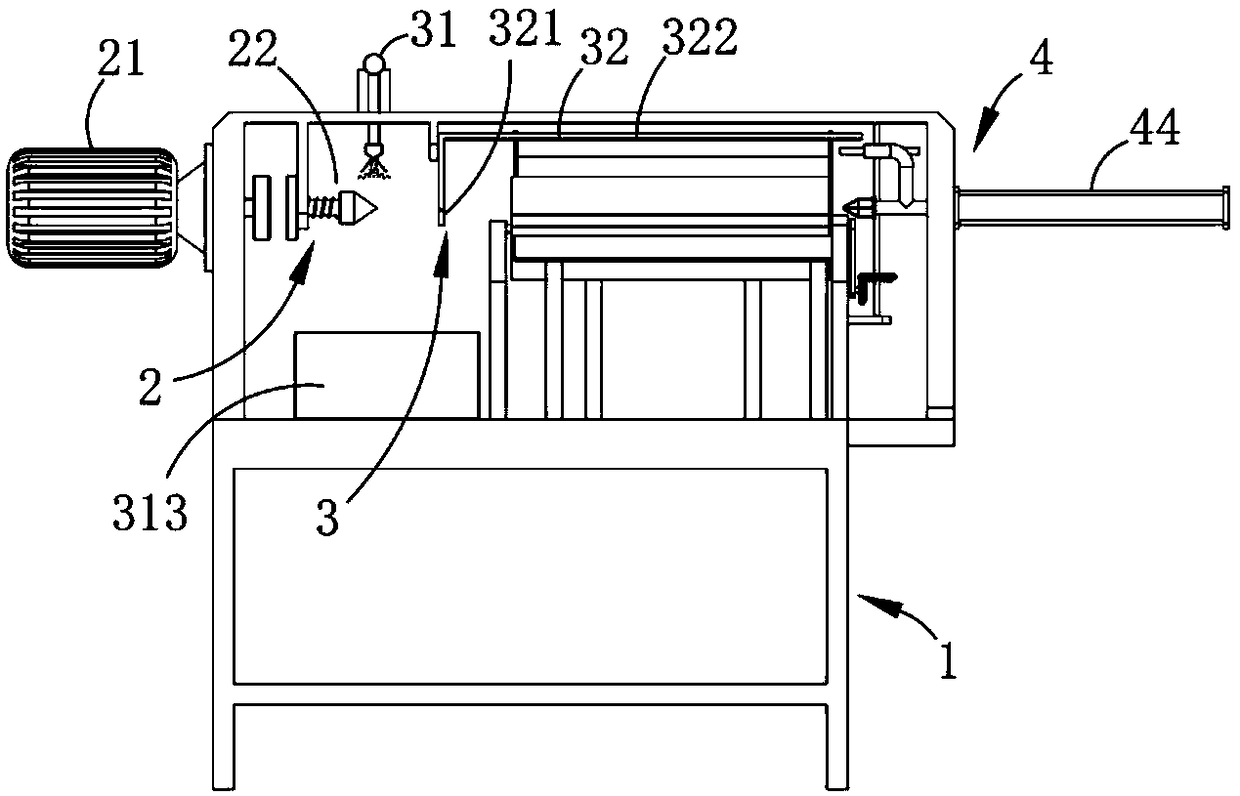

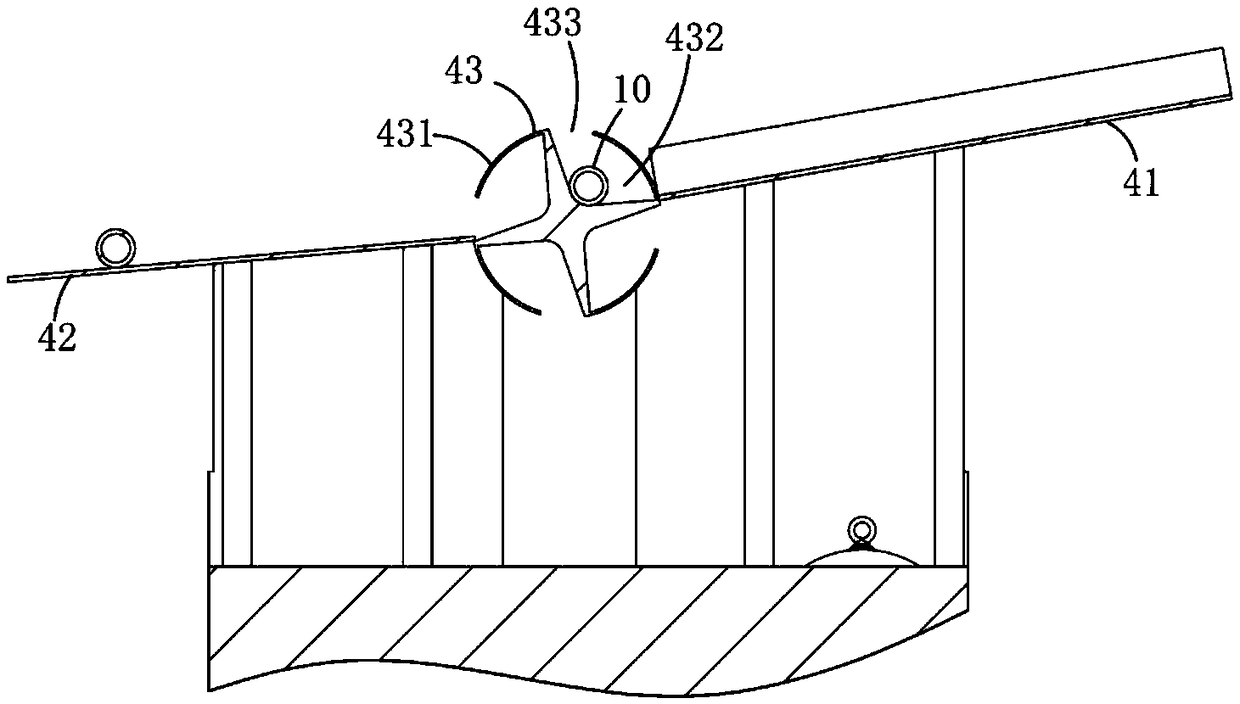

[0045] Such as figure 1 , 2 As shown in and 4, the parts identical or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; The difference is that the positioning mechanism 2 includes a driving assembly 21 and a positioning assembly 22 arranged between the driving assembly 21 and the fuel injection assembly 31, and the positioning assembly 22 is arranged in intermittent transmission connection with the driving assembly 21; In this embodiment, after the steel pipe 10 is pushed to contact the positioning assembly 22 by the pushing assembly 44 , the pushing is continued to make the positioning assembly 22 contact the driving assembly to realize the rotation of the steel pipe 10 .

[0046] Among them, such as Figure 4 As shown, the drive assembly 21 includes a transmission part 212 on which a rotating part 211 is arranged o...

Embodiment 3

[0050] Such as figure 1 , 2 As shown in and 5, the parts identical or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the difference between the second embodiment and the second embodiment is described below; The difference is that the fuel injection assembly 31 is arranged above the positioning mechanism 2, and it includes an oil pipe 311 and a nozzle 312 communicating with the oil pipe 311 for injecting oil to the steel pipe 10, and a nozzle 312 arranged under the oil nozzle 312 for oil injection. In the oil pool 313 where the oil is collected; in this embodiment, the oil injection assembly 31 is connected to the positioning assembly 22, and the friction plate 223 rotates to drive the booster paddle installed in the oil pipe 311 to rotate. The oil liquid in the oil pipe 311 is pressurized directionally by the booster paddle to realize the intermittent oil injection of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com